This is Part II of the “Sustaining the Wind” series of essays by David Jones. For Part I, click here.

This is Part II of the “Sustaining the Wind” series of essays by David Jones. For Part I, click here.

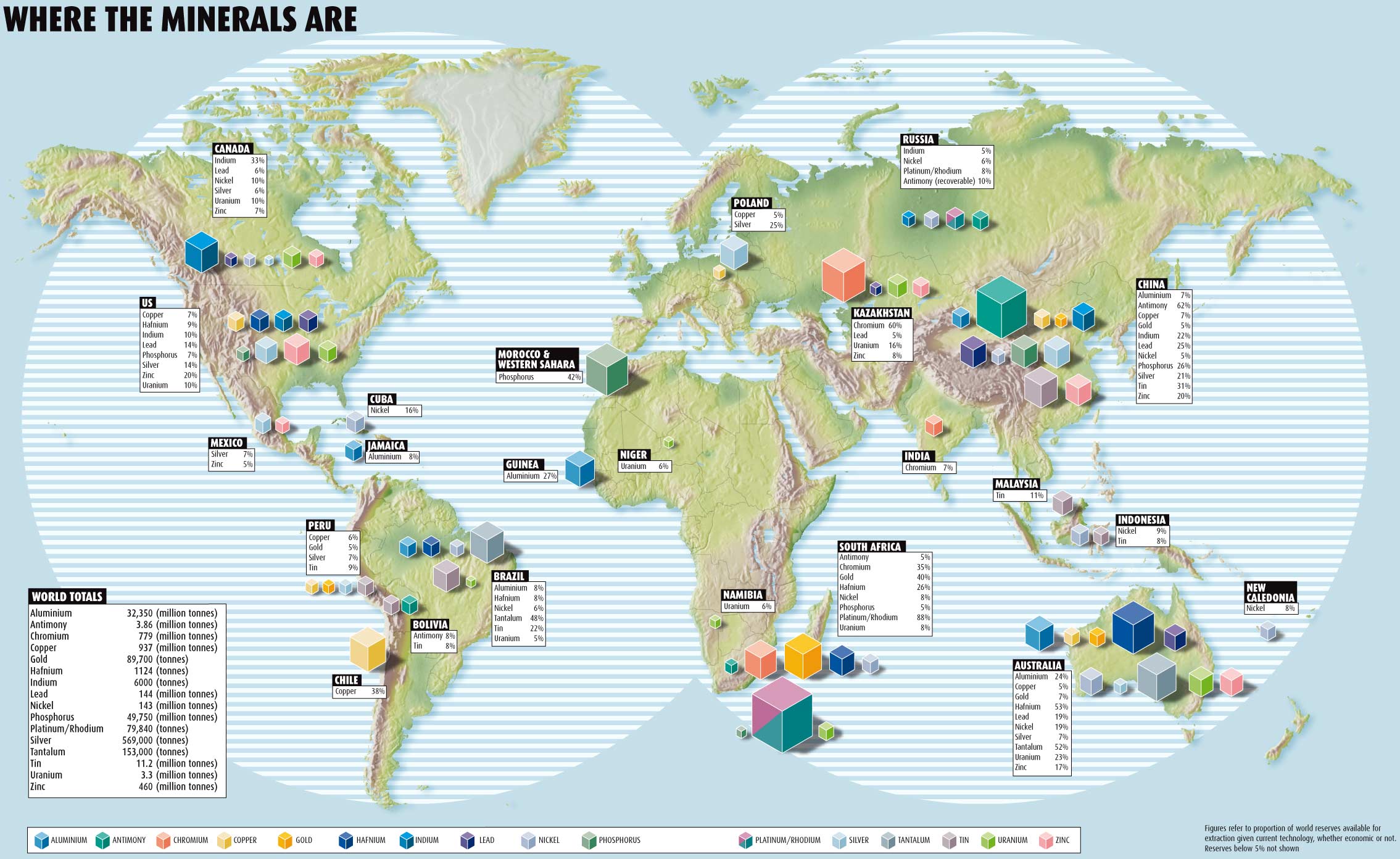

At the conclusion of part 1[i] of this series, we saw that the putative demand for the element indium in order to build some 15,000,000 wind turbines (at a nominal peak capacity of roughly 900 MW) that would be required to produce annual outputs of 90 exajoules of energy, given the low capacity utilization associated with wind infrastructure, was on the order of 18,000 tons. Although predictions about the total geological supply of any element or mineral are inherently fuzzy, we have also seen that if true, it is quite possible, that the indium demand for wind power alone, never mind the solar industry where it is a key constituent of “CIGS” (copper-indium-gallium-selenide) thin film solar cells, might well exceed the geologically available reserves of the element. In this part we will look at indium as a surrogate for the many critical elements on which modern technology depends. We noted in part 1 that a consideration demand for the elements and minerals required to construct so called “renewable energy” infrastructure is one to two orders of magnitude higher than the demand required to construct nuclear power plants. Moreover we examined data connected with the Danish database of commissioned and decommissioned wind turbines to determine that historically wind turbines remain operational of a mean period of about 15 years – with some capacity lasting a little longer than 30 years, and some for less than two years – and thus efforts to expand wind capacity – which now produces less than 2 exajoules of the more than 560 exajoules of energy humanity consumes – will involve not only adding massive new infrastructure, but also regularly replacing worn out capacity.

As we look at indium, we will not assert that the wind industry is completely dependent on access to it. It is always possible that replacements can be found for any material, as we will see, but we will nevertheless show that the game of “material musical chairs” if you will, is a profound challenge, and that often the hand waving and wishful thinking that surrounds issues in energy, especially where so called “renewable energy” is concerned, is at best glib, at worst misinformed to the point of delusion. The fate of humanity is very much dependent on the decisions we will make in this century; possibly no generation has faced such a demand for clear thinking as the immediately coming generations will face, even as the current generation has failed the future miserably.

About indium:

Indium is the 49th element, formally in group 13, in the modern periodic table, a cogener, of aluminum, gallium, thallium, all of which are metallic in their pure state, and boron, which is nonmetallic. All of these elements exhibit a chemical valence of 3. (Thallium also exhibits a +1 state and boron, like carbon, also forms a wide array of covalently bonded structures.) With the exception of aluminum, the most technologically valuable application of indium and its group 13 cogeners is in a non-metallic forms, technically ceramics[ii], as dopants in semiconductors, in things like electronics and solar cells. (Their valence state makes them formally “Lewis acids,” electron acceptor species.) Natural Indium obtained from ores contains two isotopes with mass numbers 113 and 115, with the 115 isotope dominating, representing 95.71% of the total indium. Of the two isomers, only one is stable, the minor 113 isotope. The 115 isotope is radioactive, but has a very long half-life, 4.14 X 1014 years[iii] and thus has easily survived since the accretion of the solar system from radioactive supernovae debris. Yes folks, given that one of the most wide applications of indium is to make “ITO,” indium tin oxide, a transparent electrically conducting ceramic used to make touch screens for computers and phones, if you have an iPhone in your pocket, it is radioactive, although the risk from this radioactivity, like the considerably larger amounts of radioactivity found in bananas, as well as the “Fukushima Tuna” described in Part 1 of this series, is trivial. Apparently, wind turbines also feature trivial indium related radioactivity, although we shall see in Part 4 when we discuss lanthanide mining, any radioactivity attributable to indium is dwarfed by the radioactivity associated with mining lanthanides for the production of wind turbine magnets.

A note on indium’s radioactivity: There is right now, as we’ll discuss, given the many applications for this rare metal, a considerable effort to find new sources it. As this author always makes the point that used nuclear fuel should not be regarded – as it most regrettably often is – as “waste” but rather as a resource containing some very valuable, and in many cases unique materials, it is worth noting that indium is a fission product that is found in such fuel, albeit a very minor one. The fission yields of the two isotope mass numbers that decay ultimately to stable or quasi-stable indium isotopes in question, 113 and 115, from the fast fission of plutonium’s 239 isotope, 239Pu, are, respectively, 0.148% and 0.0995%[iv]. Even if the fission products from fissioning this isotope are low, upon the removal of actinides, the concentration of indium in used nuclear fuel is on order of magnitude higher than is found in zinc ores from which it is currently commercially isolated. Such indium, were it to be isolated from used nuclear fuel, interestingly, is slightly less radioactive than natural indium, and slightly lighter. It can be shown however, that if all the world’s energy consumption today were met by the fissioning of plutonium, rather than the far less safe energy sources we employ today, the yield of indium from nuclear reactors would be relatively modest, about 8 tons per year. (Fast fission produced indium would have a significantly reduced atomic weight than “natural” indium, 113.709 g/mol for the former, vs 114.818 for the latter.)

The fact that indium is always found, with the exception of a few very rare minerals, in very dilute solid solutions has implications in both cost as well as in the environmental impact associated with its isolation. As we discussed briefly in Part 1 of this series the chief source of indium in zinc ores, where it’s concentration is generally lower than 100 parts per million. Generally, zinc is refined by “roasting,” heating its sulfide under mildly oxidizing conditions using heat. (It would be safe to assume that in most cases, the source of the primary energy for generating this heat is dangerous fossil fuels: Despite the trillion dollar expenditure in the last decade, discussed in Part 1 of this series, on so called “renewable energy” the growth in absolute terms in the use of dangerous fossil fuels continues unabated, as does the concentration of dangerous fossil fuel waste in the planetary atmosphere. Although a great deal has been published about putative “solar thermal” approaches to obtaining process heat for things like roasting zinc blende[v], the number of commercial solar zinc refining operations on the planet is zero.) Under these conditions, volatile constituents often condense in the exhaust stacks; these are known as “flue dusts.” While the precise procedures for the recovery of indium are generally industrial secrets,[vi] the general approach is understood to involve leaching these dusts with acids to collect indium and other metals, precipitating them with electrolytically obtained hydroxides – indium hydroxides are one of the most insoluble hydroxides known – and refining them electrolytically. This is obviously an energy intensive process.

A few indium based minerals are known, but they are extremely rare, and will never be of commercial importance.

This leaves seawater: In part 3 of this series, we will discuss at length the chemistry of metals in seawater, particularly the chemistry of uranium. The recovery of metals from seawater is an interesting topic. In the 1920’s, Nobel Laureate Fritz Haber, a somewhat rabid German nationalist who would later be exiled from his country on the grounds that he had Jewish ancestors – his Nobel was for inventing a process to fix nitrogen, thus making 20th and 21st century agriculture possible[vii] – made a huge effort to recover gold from seawater, where reserves vastly outstrip the quantity in terrestrial ores, this in hopes of paying off Germany’s onerous post “Great War” debt, only to fail, because the process costs at that time were more expensive at that time, the 1920’s, than the gold recovered by using it. While the recovery of gold, uranium and many other metals has been evaluated in many settings, because of the extremely low solubility of indium hydroxide – despite our best efforts to acidify it by dumping acidic dangerous fossil fuel waste into atmosphere, the ocean, being buffered by borate and other species, still remains slightly basic – indium in the ocean is found at extremely low concentrations, concentrations so low as to be barely detectable by even the most sensitive analytical instruments known.[viii] In fact, the element has been described thusly: “indium is known as one of the elements which have the lowest levels of concentration in seawater among all the elements that have ever been reported to date.”[ix]

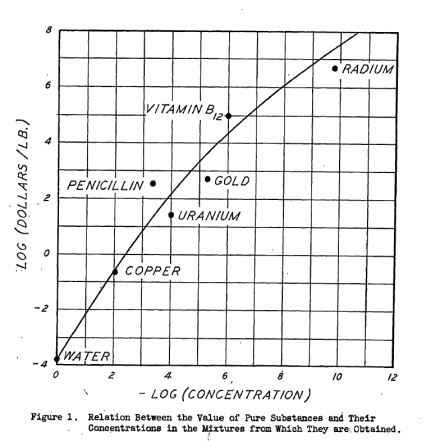

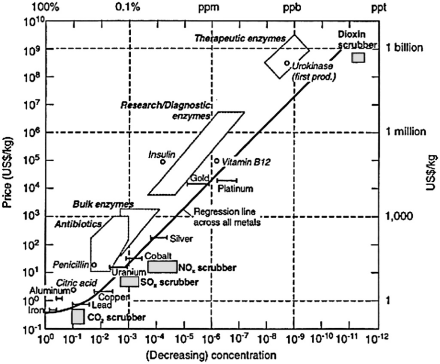

In 1959, MIT Chemical Engineer Thomas Sherwood, in an address given as he accepted the Priestly Medal – one of the highest honors that can be bestowed upon American chemists –discussed the concept of a plot that now bears his name, the “Sherwood Plot” a log-log plot of the concentration of a molecule of an element or compound in it source matrix vs. the cost of isolating it. His original plot, from the published version[x] of his award talk is here:

The reason that cost is tied to concentration is fairly obvious. Since entropy is disorder, a dilute solution has much more entropy than a pure solution, irrespective of the phase, solid, liquid or gas of the solution in question. Since a fundamental feature of the universe is to favor high entropy over low entropy, in order to overcome this entropy, “the entropy of mixing,” one must invest energy. Since energy has a cost, both economically and environmentally – internal and external costs – it always involves energy to isolate pure materials.

An updated version of the Sherwood plot, this one in connection with a study by House et al[xi] I encountered while writing an unpublished piece on the feasibility of capturing carbon dioxide from the air is below. (Note that the carbon dioxide on this particular version of the Sherwood plot refers to carbon dioxide from a scrubber that processes dangerous fossil fuel waste in “flue gas,” a relatively concentrated form of the gaseous, concentrations orders of magnitude higher than the concentration of dangerous fossil fuel waste in the atmosphere. The plot does not apply to the atmosphere containing said waste. Nevertheless, the recovery of carbon dioxide from air was the subject of the House paper. House’s paper did not evaluate the recovery of carbon dioxide from seawater, which is a different game.)

In the case of indium (not shown) it appears, that of this writing that indium prices are running around $720/kg[xii], which is less than the value one would estimate when looking at this more recent version of the Sherwood plot and considering the concentration of indium in zinc ores.

The reader should keep in mind that Sherwood plots, while useful as a first order approximation, do not necessarily account for refining process details, as well as the value of the other components of matrix from which a specific purified compound or element is produced. In the case of indium, the zinc from which it is separated has significant value; whereas in the case of therapeutic enzymes, the biological broths containing the genetically modified cell cultures from which they are separated are simply waste. Irrespective of specific cases, it is clear, to reiterate, that the reversing dilution implies an economic cost which at its basis derives from a thermodynamic cost, thermodynamic costs themselves almost always implying an environmental cost since the “currency,” if you will, of thermodynamics is energy. This is an important factor to keep in mind.

The practice of selling or distributing products which contain rare materials is in itself, if one reflects for a moment, a case of dilution whose reversal will require energy. Consider the indium tin oxide in “smart” phones. If one travels to a store to purchase such a phone, consuming a certain amount of gasoline, and then wishes to recycle the materials therein one will need to travel to the recycling center for that purpose. Unless one lives within walking distance – or bicycling distance – of such a center, energy will clearly be expended again. Following the collection process, the materials to be recycled will be shipped to a recycling plant: These days such plants can be on opposite sides of the planet from the point of collection. The reason that plants are often at the other side of the planet from the point of use is that the recycling of these materials, as we discuss briefly below with respect to indium, has rather profound health consequences on the workers engaging in these practices. Electronic waste is not only contains significant amounts of toxic elements,[xiii] but also considerable inventories of fairly toxic organic chemicals, for example, brominated diphenyl ethers, “BDE’s” utilized as flame retardants in many electronic (and other) products. As the protection of workers from these health consequences involves, in many cases, expensive equipment, it is considered more “cost effective” simply to use poor people with low levels of education to do the work, who are less likely to complain about, or even be aware of, the risks. Thus, under current conditions, only when the products have been shipped across the planet, with an expenditure of energy, to a suitably poor country – or a country with a subculture of poor people and weak environmental and health regulations – will the additional energy required to address the thermodynamically relevant operations inherent in mechanical or chemical separations of the materials to be recycled. Many efforts are made to quantify, often in terms of energy, at other times in terms of carbon dioxide generated, and sometimes in terms of health consequences, or, on a more primitive level, in terms of money, the cost of these processes. This is the general discipline of life cycle analysis, or “LCA.” The outcome of any LCA evaluation of any product will depend, of course, on one’s focus. Most frequently in the literature, in the general opinion of this author, who tends to focus on energy issues, the focus is on carbon dioxide. Nevertheless, human and environmental consequences – of which carbon dioxide is only one feature – might have, and should have, standing.

The point of all this is that, with the exception of the elements thorium and uranium which are in fact, destroyed by use, while elements cannot be destroyed, access to them can effectively be lost by the simple act of dilution. In many cases, the technology for the recovery of particular elements from very dilute sources may not exist, or may not have even been evaluated, in other cases, the thermodynamic penalty, which translates into an environmental penalty, will be too extreme to justify the process.

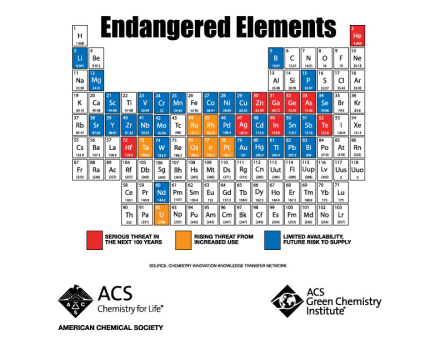

If one pokes around a bit, both in the scientific literature and elsewhere, one can find many examples – they are not all identical – of periodic tables of the elements that look like this[xiv]:

I note that one of the elements identified as being “seriously threatened” in the key of this particular version of the table, zinc (Zn), is essential to life, and six of those identified as having limited availability and future risks to supply, magnesium (Mg), phosphorous (P), manganese (Mn)[xv], cobalt (Co), copper (Cu), and selenium (Se) – the latter two are toxic in large concentrations, but essential in lower concentrations – are also essential to life, and thus, among other things, to agriculture. As we have just described previously, the exhaustion of zinc ores will certainly impact the supply of indium. It is also worth noting that all of the elements shown on this version of the periodic table in so called “CIGS” thin film solar cells of which renewable energy advocates are so proud, and on which they are willing to bet the future of the planet, are either seriously threatened or at least of “limited availability.”

That I have reproduced this periodic table here doesn’t imply that I’m totally satisfied with what it represents by the way. While I agree more or less with what it implies, I don’t think that the supplies of element 92, uranium, are as threatened as some people think, and have argued elsewhere[xvi] that supplies of element 92 might well prove infinite, at least when utilized as an energy source. I will elaborate on this argument in Part 3 of this series, and include in this part by referring to a published criticism of it in the primary scientific literature. Additionally I have expressed concern elsewhere[xvii] about the supplies element 75, Rhenium (Re), not included in this table, although I have argued that element 43, technetium, the only “ore” for which is used nuclear fuel, might replace it In its most important application, as an alloying agent in so called “superalloys” which exhibit high strength at high temperatures, as well as exceptional corrosion resistance.

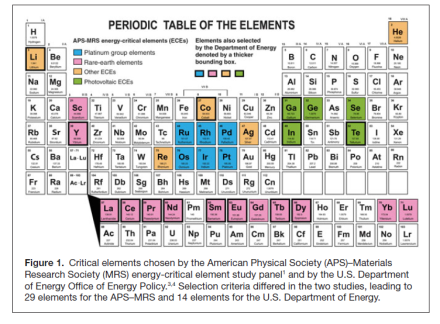

Here way of contrast, from the Materials Research Society[xviii] (MRS) is the “energy critical” threatened elements as defined, in concert with the MRS by the US Department of Energy:

It is interesting that this different periodic table, of “threatened elements” for the energy industry- it does rightly include rhenium – doesn’t include element 48, cadmium, even though this toxic element, along with the toxic elements selenium and/or tellurium, has played an important role in the absurdly expensive and poorly producing solar PV industry, a technology alternate to “CIGS.” (In China, which dominates world supplies of cadmium much as it dominates the world supply of lanthanides, up to 70% of the rice crop in markets in Southern China has been shown to have cadmium contamination levels of concern, with 10% of the rice crop having levels of concern for the nation as a whole.[xix] (But don’t worry; be happy; solar PV is “green” energy.)

We might imagine, including cadmium, selenium and tellurium for the solar industry, a periodic table of “threatening elements” which would include several elements widely distributed in the planet’s atmosphere (and ultimately its soil and water supplies) because of the very stupid practice of burning coal and dumping its wastes indiscriminately; this list would include of course, mercury, lead, and carbon, but no matter…

The standard rebuttal to any argument about the depletion of any resource is that when the resource in question becomes scarce, either that higher prices will impel new discoveries of sources, utilization of lower grade or more difficult to access resources (as supported by higher prices as supplies dwindle), with such access improved by new technologies, or the development a suitable replacement will be found by the application of new scientific discoveries and their development into technologies. In the short term – and we are a culture of short term thinkers with no sense of scale, least of all a sense of time scales – there is much evidence to support this objection to scarcity arguments.

The most recent example of this case in support of these arguments is that of petroleum, the dangerous fossil fuel whose waste products in the form of air pollution are responsible of many millions of deaths over the last decade, and indeed, tens of millions of deaths in the decades preceding. In recent times, there was a huge international discussion of “peak oil,” all stemming from work published in the 1950’s and 1960’s by M. King Hubbert, a Shell Oil geologist, stating that oil production would follow a more or less Gaussian curve when plotted against time. At one time there was a well trafficked US blog devoted to the subject, The Oil Drum,[xx] to which posting stopped in 2013, probably because despite the excitable enthusiasm – to the point of near breathlessness – of the website’s patrons, hydraulic fracturing – “fracking” – made their predictions of the “disaster” of oil depletion seem specious. Even though I’m right in the middle of an appeal to a “peak indium” argument, which may or may not also prove specious – God forbid that we lose access to our iPhones – let me be clear that I have generally found “peak oilers” to be annoying. It’s not like I enjoy hanging out with these kinds of people. Indeed, admittedly my impression of the Oil Drum website’s patrons is based on a few cursory visits, one to a deliciously funny post there about one of my least favorite energy commentators, the rote anti-nuke Amory Lovins[xxi].

Peak oilers annoy me because of my feeling is that they have bordered on making an argument that dangerous petroleum, as opposed to air and water, was essential to life, that if we ran out of fossil oil, it would be the end of everything, our cities, our culture, even our food supplies. (A particularly egregious example of this unfortunate mentality is represented by a book written by the barely scientifically literate journalist – is there any other kind of journalist these days? – called “The Long Emergency[xxii]” by James Kunstler. The book is self-reported by the author to be a work of “non-fiction” even though it contains an dystopian account of a future – devoid, unsurprisingly of the literary depth of an Orwell or a Huxley – in which the author delineates the new borders of the putative nations of the disintegrated United States, which will include Mexico, Mexico having finally recovered the territory stolen from it in the military conquest of the American Southwest by the unjust war of 1848.)

From where I sit, this sort of rhetoric about how the loss of oil will be the end of the world as we know it can only inspire more homicidal adventures like the two US-Iraq wars, and one thinks, other awful outcomes, including the employment of technologies of the type that resulted in the Deepwater Horizon tragedy, not to mention the mining and processing of oil sands. Speaking only for myself, I am convinced, after much study of the issue, that in a sensible world, dangerous oil and dangerous natural gas would be replaced by superior options, with nuclear energy as the primary energy source, that are clearly technically feasible. Unlike the “peak oilers” I am not disturbed by the fact that we might someday run out of oil, but by the fact that we haven’t done so already.

I refer to peak oilers because this entire discourse was inspired by an excerpt of comment in my first post on Brave New Climate which I reproduce here:

First thank you for an interesting article and many interesting comments as well. I agree with you that Tesla style thinking is impractical to deliver cheap and environmentally safe transportation to the masses…

… What I simply do not understand is your strong anti wind views…

…As much as I agree that there never will be shortage of nuclear fuel provided breeder designs such as those you describe materializes, then you have to factor in cost of Uranium extraction provided that (sic) the methods you suggest. Ugo Bardi has in his study “Extracting Minerals from Seawater” analyzed the economic viability of extracting various metals from sea water and found limited grounds for optimism due to huge energy cost…[xxiii]

The author of this comment – before lapsing into a discussion of Saudi oil prices, about which I personally couldn’t care less, and after announcing with bourgeois surety that “cost is king” (as opposed to suggesting that considerations about human decency might also have standing in decision making) – did not provide a reference for the “Extracting Minerals from Seawater,” “study” to which he referred. (I almost always want to roll my eyes when a defender of the so called “renewable energy” industry refers vaguely to a “study.”) Nevertheless, having probably spent several weeks of my life searching for, collecting, reading and contemplating papers about the extraction of uranium from seawater, all the while never having heard of Ugo Bardi, reference to whom was supposed to stop me in my tracks as I considered the point, I decided to look into him and see what was in the “study” in question assuming I could find it.

On locating Ugo Bardi’s paper[xxiv] entitled “analyzing the economic viability of extracting various metals from seawater,” I was unsurprised to see that of the thirty-three references in the paper, three were to posts on The Oil Drum, (one of which was written by Bardi himself), and two were to the website[xxv] of “ASPO Italia,” which one can garner, even if one doesn’t speak Italian, is an Italian “Peak Oil” website. One of the ASPO Italia web posts referenced in his “study” was written by Bardi himself and the other to a link reproducing a 1970 paper, in Italian, on the extraction of uranium from seawater. Two other references seem to refer to thorium in seawater, which is completely irrelevant to a discussion of uranium in seawater, since thorium is almost completely insoluble in seawater, the solubility for thorium being on the order of pg/liter as opposed to μg/liter of uranium (as a carbonate complex)[xxvi], the difference a factor of roughly 1000. Of the four other references that are actually references to papers from the primary scientific literature and actually extraction of uranium from seawater, two date from 2003, and one of dates to 1982, and the other to 1983. A Google Scholar search on amidoxime resins and uranium – amidoxime resins are just one technology for the separation of uranium from very dilute matrices such as seawater – shows that during and before 2010 approximately 1,000 papers were published on the subject, 65 of which were published in 2009 alone. To repeat, this count refers only to amidoxime technology, which is hardly the only technology for the solid phase extraction of uranium. More recent publications detail entirely different approaches for solid phase extraction. For example an appeal to resins having primary amines[xxvii] which are said to have a mass efficiency that is three to four times greater than amidoxime resins has been recently published. An intriguing paper is now apparently in press,[xxviii] claims to have a process utilizing activated carbon electrodes, which, crudely analyzed – should the claims hold up which is in no way assured – that may produce uranium from seawater in a price range between $23/kg and $460/kg. The higher figure would have little effect on the cost of nuclear power, since the cost of fuel is a trivial component of nuclear generating costs. The lower figure is significantly lower than the cost of uranium from terrestrial ores using extraction systems now utilized.

We will address, at considerable length, aspects of the question of “peak uranium,” in part 3 after we finish raising the point for “peak indium,” as it applies to the wind industry and other industries, most notably the solar industry, where issues connected to it are being discussed.

I will confess, that on reading the paper[xxix] I referenced in Part I of this series relating to the quantities of various “critical” elements and compounds used in wind turbines that I was surprised to see indium listed among elements utilized by the wind industry. Gold, silver, platinum one can believe in electric contacts or conductors, the conflict metal tantalum in electrical components such as inverter capacitors, as well, but indium…indium…

Without wasting too much time digging into the engineering of a technology, wind energy technology, that has thus far proved demonstrably nearly worthless (despite massive consumption of resources, as noted at the outset of this series), one can speculate on the function of indium in wind turbines. Since the 1940’s[xxx], indium has been widely used in making coating alloys for bearings that show high wear resistance. The rationale for using a soft metal or alloy for this application – often the indium is electrolytically coated on bearings in the form of a lead-indium alloy – is apparently involved with lubricity.[xxxi]

One might also reason thusly: Indium tin oxide is a piezoelectric material, one that generates an electric signal or current in response to the application of pressure. Much as “smart phones” respond to pressure from fingers, it seems that devices can be constructed using indium tin oxide to measure wind pressure, speed and direction, and thus can be utilized as control elements to, for instance, control the yaw of a turbine or turbine blades to minimize the potential for damage, or to balance load in fluctuating weather systems. It’s easy to imagine such a thing, but it turns out that there is little evidence to support this application.

So neither of these cases, appear anywhere in the literature of wind turbines, at least as far as my admittedly cursory approach to the question suggests. It is perhaps more reasonable that some indium ends up in bearings in wind turbines, than it is that a piezoelectric system is involved. It turns out, however, that this author’s speculation is not too far from the mark. More likely the application is a LIDAR (Light Detection And Ranging) system[xxxii] for measuring wind speed, a related application although not a piezoelectric application but rather an optical application, in order to adjust the turbine blade pitch for load reduction by measuring wind speed at a distance from the detector itself. In this case, the indium is used in a detector for laser light; one type of detector for this system is a gallium arsenide indium antimonide, GaAsInSb, composite of two ceramics.[xxxiii] Note that all four elements in this ceramic are identified in the first periodic table in this part as being of concern, three of them identified as being of “serious concern.” It needs to be stated that the application for these types of detectors is hardly restricted to the wind industry. Similar devices certainly have applications elsewhere, the air traffic safety industry for example (and as much as people like this author may object, to military applications). A similar technology utilizing the a very similar kind of detector, substituting an atom of arsenic (As) for an atom of antimony (Sb) albeit not for wind speed measurement, has been proposed for the noninvasive biological and medical imaging using near infrared energy.[xxxiv]

The application here, the conversion of energy from a light source, in this case laser light, to an electrical signal or current, of course, far more important to the so called “renewable” solar industry than it is to the wind industry. Indeed, many of the papers written about the putative shortage of indium concern the solar industry, this, again, in connection with the “CIGS” thin film technology. A paper[xxxv] published by the US NREL (National Renewable Energy Lab) on the long term degradation rate of CIGS solar cells – no, they do not last “forever” – notes at its outset that as of 2008 these were the most “efficient” solar cells available. Now, if you are old enough to have outgrown your pimples and if you have been paying attention to the so called “renewable energy” rhetoric, you have certainly lived through a fairly large share of breathless “solar breakthrough” announcements of reduced cost and higher efficiency, as if this process were to go on indefinitely.[xxxvi] Nevertheless, as of 2015, the solar industry remains a trivial form of energy. In contrast to the dangerous petroleum industry that is or was of such concern to “peak oilers,” if the solar industry were to vanish tomorrow, no one would notice, whereas – even though it is certainly replaceable on a sufficiently lengthy time scale – if the petroleum industry were to vanish tomorrow, pretty much everyone would notice. This said, we are already discussing shortages of critical materials. A publication[xxxvii] from the same organization, NREL, which is certainly not unenthusiastic about the so called “renewable energy” industry, since the jobs of everyone working there, depends on it, has this to say on the subject:

For PV to achieve energy significance will require global annual production levels on the order of hundreds of GWs to TWs. If we are to become an industry of such a size, one key-enabling factor will be to avert potentially debilitating increases in the prices for critical feedstock materials. This will require a detailed plan, especially with regards to a timely coordination between the desired level of PV deployment and the corresponding supply of modules. In order to enable manufacturing the PV technologies that have been discussed at the hundreds of GWs to TWs scale, it is apparent that the supply base for the critical elements tellurium, indium and gallium will need to be expanded.

Note the words, written just two years ago by experts in the field after decades of cheering for solar energy “For PV to achieve energy significance…will require 100s of GW to TW…”

A terawatt of energy operating at 100% capacity utilization for one year, a “terawatt-year” is just shy of 32 exajoules, this would be out of the 560 exajoules humanity now consumes each year. (Today the solar industry produces less than one exajoule of energy per year.) However the solar industry will never operate at 100% capacity utilization since it is widely reported in various places around the world that the sun appears to go down every day, and sometimes, in some places, it gets cloudy, or it rains, or it even snows. So here we have an insignificant industry, operating at significant costs, producing very little energy and already worried about supply shortages.

It’s a good thing we didn’t bet the future of the planetary atmosphere on this technology, um…um…um…or did we, are we?

The question is though, is indium essential for wind turbines, or might not an alternate technology be developed that serves to accomplish the same task? If not, is it possible to locate other sources of indium?

With respect to the second question 600 metric tons per year – or even three or four times as much – of indium seems a rather modest requirement when compared to the still modest amount of ten thousand or so metric tons of uranium to which I have obliquely referred herein and which we will address at length in Part 3. Unfortunately, as discussed above, the concentration of indium in seawater – its concentration is not homogenous throughout the ocean – is extremely low[xxxviii], three to four orders of magnitude lower than that of uranium. Although we will discuss the extraction of uranium with solid phase resins, including the amidoximes mentioned above, solid phase resin equivalents for the extraction of indium from seawater have been developed mostly for analytical chemistry purposes, to concentrate indium to levels at which sensitive instruments such as ICP-MS can detect it.[xxxix]

As for other sources, it does appear that some other ores similar to zinc blende ores, lead sulfide ores, may contain indium[xl], which may be separated from flue dusts. It’s not clear that this will result in a huge increase in supply. One doubts it.

Of course, in many cases like this there is a lot of talk about recycling. Let’s be fair, those of us who advocate for nuclear energy use the word “recycling” frequently. In the case of indium, great deal has been written about recycling it. Indium recycling has been under quite a bit of discussion lately. Rather elaborate solid phase resins[xli] have been developed for the extraction of indium from waste waters, and from “urbine mines,” aka electronic waste heaps. It is often, practically always, assumed that so called “renewable energy” is “safe,” but as it turns out, recycling and indeed, processing of indium has a significant health risk to workers in the industry. At least two deaths – this in a relatively small industry – have already been reported[xlii] among indium workers. It is now well understood that working with indium tin oxide, ITO, without protective gear leads to lung disease and that this disease is irreversible, and again, can have fatal consequences. Reading through an account[xliii] by Chinese scientists of their process for recycling ITO, this in a journal devoted to “sustainable” chemistry, caused me to shudder as I thought of the health of the poor graduate students who probably did the laboratory operations: I hope I’m misunderstanding their process. In any case, whether or not this disease is associated with the chemical form of the indium, the tin oxide utilized in cell phone and computer touch screens, is not clear. This said, one should note that since indium recycling will involve acid leaching, given the extreme insolubility of its basic form as mentioned earlier, in the case of CIGS, containing selenium, hydrogen selenide is sure to be generated during the processing, since this is a risk whenever selenium or its inorganic compounds are treated with acid. Hydrogen selenide is an extremely toxic gas, one that is industrially utilized to be sure, but one that certainly has the potential for tragic accidents. Now the fact that hydrogen selenide is toxic does not mean that it cannot and should not be handled. If we banned all hazardous materials and operations, our technological society would rapidly collapse and we would face a new set of risks resulting from a reduced life expectancy as was observed just a century or two ago. Any nuclear energy advocate such as myself would be entirely disingenuous to claim otherwise, some (but not all) nuclear materials are extremely hazardous, though few, gram for gram, as immediately hazardous as hydrogen selenide gas, apparently 300 ppb for an 8 hour exposure will kill a guinea pig[xliv]. The extent to which the recycling of nuclear materials would be of more or less risk than the recycling of indium is, at least in part, a function of the mass intensity. A putative wind or solar industry has, the point being driven here, a extremely low energy to mass ratio compared to nuclear energy. Therefore any attempt to recycle materials connected with a putative so called “renewable energy” industry will involve a huge amount of mass transfer, even a larger scale than the dangerous fossil fuel industry.

Finally, no amount of recycling will be useful to sustain an industry if the total availability of the element being recycled is less than the industry requires. In the case of indium, it’s not clear that any of the demands on the industry, be it computer and cell phone screens, solar cells or other applications can scale much higher than they already have. Therefore it is probably silly to speculate about recycling the indium in “CIGS” solar cells, although people do so.[xlv] Their clearly isn’t enough indium on the planet to make “CIGS” type solar cells a meaningful form of energy, where we define meaningful as being at least at a 10 exajoule per year in scale.[xlvi] Therefore it is useful, probably also wise, to ask the question “Why bother?” when addressing this particular “solar breakthrough.”

With respect to the other question raised above, “do replacements for indium exist?” huge efforts, in support of the electronic device industry, are being made to accomplish the piezoelectric task without the use of indium. Many of these approaches are involved in studies of the properties of graphene or functionalized graphene, graphene being a material that consists of a single atomic layer of carbon atoms arranged as they are in sheets that make up the structure of graphite. Similar options may exist for many of the “critical elements” we’ve been discussing.

Indium however, as we defined at the outset of this part, is just a representative case; it is certainly not the only case of an element that may not be available on scale for many of its potential. Generally, indium is the element is thought to be the industrially important element in the most danger of depletion, some people claim its supplies will be severely constrained, if not vanished, in 10 to 15 years, but even if this does not happen other elements will surely follow the same path, as the periodic tables shown above make clear.

Now, let’s be generous and assume that my speculations for the use of indium in wind turbines are correct. Any use in bearings is probably trivial to replace; materials science today is so advanced with respect to tribological studies that it is difficult to imagine that many alternatives to the use of indium in bearings are not possible. It is also very unlikely that it is impossible to develop an alternative for GaAsInSb detectors in LIDAR wind speed detectors. Of course, it should be intuitively obvious that one could pretty much eliminate the entire LIDAR system with a simple mechanical anemometer. However a related question is whether the replacement will function as well as the original. Almost certainly the LIDAR units on wind turbines are designed to change the pitch of the blades before wind bursts strike the turbines, not during the burst. Wind turbines today are massive machines, pretty much useless machines where addressing climate change is concerned, but nevertheless massive. Presumably huge torques are developed, huge stresses, and the rate at which these stresses take place will have important implications with respect to their lifetimes. If a device needs to experience a strain in order to detect a strain, this will obviously require design constraints and require higher, possibly more expensive and less reliable, design tolerances. In Part 1 of this series, we have already discovered that wind turbines historically have had relatively short lifetimes, on the order of one or two decades – rarely three decades. It is quite possible that untested alternative technologies to those currently in use will negatively impact these already insufficient lifetimes.

And let’s be clear about something: We are running out of time. Many serious environmental issues are already exigent, most famously, but not uniquely, climate change. We don’t have another half a century for performing “R&D” during which we will promise one another that so called “renewable energy” will work. We’ve been at more than 400 ppm of carbon dioxide for most of 2015. “Time’s up!”

To reiterate, shatever the current case might be, it is incumbent to ask whether the replace of LIDAR systems using GaAsInSb or something very much like it might not have a profound effect on the sustainability of the wind industry. The conceit of the so called “renewable energy” business is that their products will continually improve, but if things like LIDAR – and one can imagine thousands of permutations of other types of systems of subtle but real import – are unavailable, or available only at levels that function with shorter lifetimes or less efficiency, this claim of continuous improvement in cost and reliability becomes more dubious. It is possible that resource constraints will make these products worse performers, in spite of the fact that after a half a century of excited marketing about how wonderful they are (or more often “will be” or “could be”) are still not working very well.

The operative point, to summarize, is that the so called “renewable energy” industry has an intensive mass requirement, even higher than the unacceptably high mass requirement associated with the dangerous fossil fuel industry, and as is the case, ultimately if not immediately in the case of dangerous fossil fuels, many of the elements on which it depends are not infinitely available and are not renewable, the advertised name for the industry, the renewable industry, needs to be questioned to see whether it is, in fact, an oxymoron at best, doublespeak at worst. The argument presented here suggests that it is anything but “renewable.”

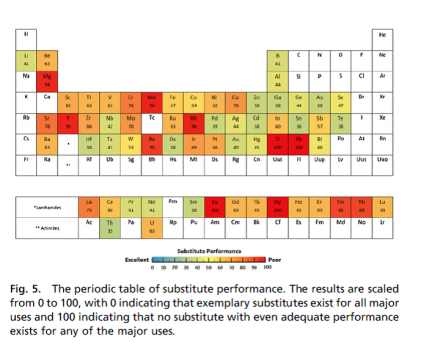

In closing, let’s take a look at yet another of the “critical elements” periodic tables[xlvii], this one which ranks the elements on how easy it is to develop alternate, at least as we understand the case today, approaches to the technologies that employ them should their supplies vanish:

We see that indium, (In) has a score of 60, in this rendering meaning that replacement of it is deemed possible by the authors of the paper from which it is reproduced, although that the replacement material might not function as optimally as indium itself does. Of course, in the case of the wind energy industry, which already has a very low level of performance even with optimal materials, one wonders how many such substitutions the industry could afford without making its marginal performance even worse.

In the periodic table above, one of the elements considered most irreplaceable is the lanthanide element dysprosium, (Dy) which has a score of 100, according to the authors of the paper, thus being irreplaceable. One of the major consumers of dysprosium on the planet is, in fact, the wind industry.

In part 4 of this series, we’ll take a closer look at dysprosium, and speculate, as many have, on what it means to the sustainability of the wind industry. And let’s note something else; in all these questions we raise, we will not be concerned with merely our generation, or even the next two generations or the next five or the next fifty. We need to concern ourselves with all generations, something we will take a stab at doing in the next part, part 3, when we look at uranium.

Have a nice day. I’ll see you next time.

[i] NNadir (Brave New Climate) Sustaining the Wind, Part 1.

[ii] C. Barry Carter, M. Grant Norton, Ceramic Materials, Springer, 2013. Ceramics are broadly defined in this excellent introductory text on ceramics as “a nonmetallic inorganic solid material” a definition which includes things like table salt as well as diamonds. (cf. page 4)

[iii] IAEA Table of Nuclides (Accessed June 20, 2015)

[iv] NNadir, (Brave New Climate) Current World Energy Demand, Ethical World Energy Demand, and the Centuries to Come See reference 18 therein for the source of the data and a description of how to generate this data from the BNL data pages.

[v] L.O. Schunka, W. Lipinski , A. Steinfeld Chemical Engineering Journal 150 (2009) 502–508. This paper actually refers to a process involving the thermal dissociation of zinc oxide, which is similar to the thermal dissociation of zinc blende ores (zinc sulfide). The thermal dissociation of zinc oxide can be incorporated into the ZnO hydrogen cycle designed to split water into hydrogen and oxygen. Another variant of this cycle reduces carbon dioxide to the monoxide, affording access (with hydrogen) to “syn gas” which can be utilized in the replacement of pretty much every important product now obtained from dangerous fossil fuels, in particular petroleum. These processes may be confidently predicted to never be sustainable with solar energy, however they may be adapted to nuclear energy, if supplies of zinc can be sustained.

[vi] Thomas Goonan, Material Flows of Indium in the United States 2007-2008, USGS Circular 1377, (2012).

[vii] Vaclav Smil, Enriching the Earth, MIT Press, 2000. One of the most fascinating and interesting books on the history of technology I have ever read.

[viii] Amikawa, Alibo, and Nozaki, Geophys. Res. Lett. 23, 18, 2473-2476 (1996) . Although the sensitivity of ICP-MS has greatly improved over the last 20 years, the detection limits at the 60 to 90 femtomole per kg level claimed for Pacific Ocean seawater would still be a challenge, particularly today, where one might easily find contamination from electronic devices in the lab, or in the pockets of lab scientists and technicians carrying phones.

[ix] Masahiko Murakami, Naoki Furuta Analytica Chimica Acta 556 (2006) 423–429

[x] Thomas Sherwood, Mass Transfer Between Phases, 33rd Annual Priestly Lectures, April 13-17, 1959, Published by the Pennsylvania State University, University Park, PA copyright 1959.

[xi] Kurt Zenz House, Antonio C. Baclig, Manya Ranjan, Ernst A. van Nierop, Jennifer Wilcox, and Howard J. Herzog PNAS108 (2011) 51, 20428-20433 (Reproduced from Grübler, (1998) Technology and Global Change (Cambridge Univ Press, Cambridge,UK)).

[xii] Mineral prices website. (Accessed June 14, 2015)

[xiii] For a recent review of this widely discussed issue, see: Jinhui Li, Xianlai Zeng,,† Mengjun Chen, Oladele A. Ogunseitan, and Ab Stevels Environ. Sci. Technol. 2015, 49, 7095−7108 . The supplementary information of this paper gives a nice breakdown of the countries of origin of electronic waste, predictably dominated by the United States, as well as the types and forms of the waste. A table in this information (table S2) also remarks on the likely lifetime of supplies of “endangered element” supplies, giving the figure, for indium, of 13 years.

[xiv] American Chemical Society Endangered Elements Web Page (Accessed May 31, 2015)

[xv] As an aside, for a very interesting account of the importance of manganese c2ontaining enzymes and their interaction with another “threatened element,” phosphorous – phosphorous besides being important in nucleic acids and in the proteomics of kinases, accounts for the energy storage device used by all living cells – see Dharmit Mistry and Nicholas Powles Org. Biomol. Chem., 2013,11, 5727-5733. While it may be irrelevant to the discussion at hand, it appears that bacterial species manage phosphorous chemistry with “type II” PPPases (phosphoryl anhydride cleaving enzymes) which contain four manganese atoms, while higher organisms depend on “type I” PPPases with enzymes containing three magnesium atoms.

[xvi] NNadir, Atomic Insights: On Plutonium, On Nuclear War, On Nuclear Peace

[xvii] NNadir, Technetium: Dangerous Nuclear Energy Waste or Essential Strategic Resource?

[xviii] Alan J. Hurd , Ronald L. Kelley , Roderick G. Eggert , and Min-Ha Lee MRS Bulletin.37.4.2012.405-410

[xix] Hon-Ming Lam, Justin Remais, Ming-Chiu Fung, Liqing Xu, Samuel Sai-Ming Sun Lancet 2013; 381: 2044–53

[xx] The Oil Drum: An End to Eight Years (Posted July 3, 2013), (Accessed June 14, 2015)

[xxi] The Oil Drum: How Walkable Is Your Neighborhood? (Posted by “Glenn” August 26, 2007, Accessed June 14, 2015.) The post refers to the walkability of the offices of the Rocky Mountain Institute, RMI, headed by energy conservation guru, Amory Lovins, who bills himself as “chief scientist,” of RMI, even if, speaking only for myself, I regard his exposure to scientific knowledge and processes to be rather weak. Amory Lovins is very proud of his mansion in the mountains, which – despite his insistence that its existence is somehow relevant to the broad question of energy and the environment – would be irreproducible for any of this planet’s inhabitants who are not living in the top 1% in terms of wealth. Lovins is nonetheless pleased to invite you to tour his mansion, so you can learn how to be just like him, or if you cannot afford to be just like him, at least learn to envy him. The tour guide for the obscene structure, replete with instructions about what you can and cannot touch while in this temple of human excess, is here: RMI Lovins Home Tour Guide.

The “Walkscore” website is still functional: Walkscore. The “walkability score” for the address on tour guide, 1739 Snowmass Creek Drive, Snowmass CO 81654, as of this writing, (June 14, 2015), is zero. (Snowmass, CO, for those who don’t know, is a suburb of Aspen, CO known for its insanely rich and often sybaritic inhabitants.)

If, however, you still wish to drive up into the mountains to visit this structure despite my condemnation of what this monstrous paean to bourgeois indifference and insensibility represents, don’t worry; be happy: There’s plenty of parking.

[xxii] James Kunstler, The Long Emergency, Atlantic Monthly Press, Copyright 2005. The dystopian fiction “Living in the Long Emergency” part of the book begins on page 235 and one can suffer through it if one is in need of a soporific up to page 307, whereupon, thankfully, the whole bit ends.

[xxiii] Op. Cit. Ref. 1. The comment in question, by “Jens Stubbe” was made on April 29, 2015. Later in the comments section of the post, Stubbe makes criticisms of nuclear energy that may have been remotely viable in the 1970’s, when the first nuclear era was struggling with FOAKE (First of a Kind Engineering) issues, but when made today are reflection a low level of familiarity with mature nuclear technology. For example, there are no examples, none, of any kind of electricity generating plants, not even coal plants, which can match nuclear plants for capacity utilization. The persistence of these kinds of sloganeering memes – in this case the claim that nuclear energy is unreliable – long after they have become irrelevant and untrue shows an inflexibility of thinking that borders on being definable as dogmatism.

[xxiv] Ugo Bardi, Sustainability 2010, 2, 980-992

[xxv] Website of Associazione per lo Studio del Picco del Petrolio

[xxvi] S. Krishnaswami and J. Kirk Cochrane, eds. U-Th Nuclides in Aquatic Systems. Vol 13 of the Radioactivity in the Environment Series, Chapter 7, U and Th-Series Nuclides as Tracers of Particle Dynamics, Scavenging and Biogeochemical cycles, by M.M. Rutgers van der Loeff and W. Geibert, Elsevier, 2008.

The solubility of U isotopes and Th isotopes in seawater, including those in the two uranium decay series are discussed on pg. 228 (uranium) and pg. 230 (thorium). The generally accepted value for the concentration of uranium in seawater is 3.3 ppb. Back calculating from the figures in this text expressed as dpm m-3 determined from nuclear decay – internally referring to two different papers from 1986 and 2002 – I calculate 3.7 ppb for the cited numbers. The solubility of uranium is, however, not actually uniform in the oceans, being a function of salinity and thus density, which likewise varies with depth, temperature and location, as well as well as also dynamic carbon dioxide concentrations, and this may account for any discrepancies. In any case, this fascinating volume will tell you everything you want to know about the members of the three naturally occurring extant actinide decay series in the hydrosphere and atmosphere, the 232Th decay series, the 235U decay series, and the 238U decay series, and the use of their components as tracers for a wide variety of atmospheric and oceanographic processes. (The fourth series, the 249Cf/237Np/233U series is, of course, extinct on earth, although many people would like to revive it.)

An interesting thing I learned in this text was that there is disequilibrium in the 234U/238U ratio of 1.14 in seawater, and other matrices apparently related to the injection of 234U into seawater and other matrices as a result of the recoil velocity associated with the decay of its parent 234Th, itself the daughter of 238U found in rocks. (See page 228.) This fact could surely be useful in estimating the surface area of submarine rocks, and thus recharge rates of uranium to seawater directly from exposed submarine rock, were the seas in fact “mined” by solid phase extraction to obtain uranium for fuel purposes.

This topic, recharge of uranium to seawater, will be a major focus of part 3 of this series.

[xxvii] Remy Sellin and Spiro D. Alexandratos, Ind. Eng. Chem. Res. 2013, 52, 11792−11797

[xxviii] Azan Fazli Ismail and Man-Sung Yim Nuclear Engineering and Technology (2015), http://dx.doi.org/10.1016/ (Uncorrected Proof, accessed June 21, 2015.)

[xxix] Junbeum Kim, Bertrand Guillaume Jinwook Chung, Yongwoo Hwang Applied Energy 139 (2015) 327–334

[xxx] W.S. Murray, US Patent 2465329, May 22, 1944

[xxxi] D. R. Eastham, J. Eng. Gas Turbines Power 115(4), 706-710 (1993)

[xxxii] Dunne, Smiley, and Pao, NREL/SR-5000-52098 Subcontract Report (2011)

[xxxiii] Tamer F. Refaat, M. Nural Abedin, Grady J. Koch, Upendra Singh, NASA-TP-2003-212140 (2003)

[xxxiv] Shigehiro Kitamura, Masaya Senshu, Toshio Katsuyama, Yuji Hino, Nobuhiko Ozaki, Shunsuke Ohkouchi, Yoshimasa Sugimoto and Richard A Hogg Nanoscale Research Letters (2015) 10:231

[xxxv] J.A. del Cueto, S. Rummel, B. Kroposki, and A. Anderberg, NREL Conference Paper NREL/CP-520-42856 (2008)

[xxxvi] A fun commentary on “breathless” announcements of “solar breakthroughs,” this in connection with organic solar cells was published nearly ten years ago: Gilles Dennler and co-signatories, Materials Today, Vol. 10, Iss. 11, page 56, (2007) One suspects the plea from solar researchers therein has gone unheeded. Organic solar cells, so far as I’m aware, have not saved the world, despite all of the numbers of “breakthroughs” announced that generated this commentary.

[xxxvii] Michael Woodhouse, Alan Goodrich, Robert Margolis, Ted L. James, Martin Lokanc, and Roderick Eggert IEEE Journal of photovoltaics Vol. 3, No. 2, APRIL 2013

[xxxviii] Sarah Jane O. White and Harold Hemond, Critical Reviews in Environmental Science and Technology, 42:155–186, 2012

[xxxix] For an example see, Masahiko Murakami, Naoki Furuta, Analytica Chimica Acta 556 (2006) 423–429

[xl] Hikaru Sawai, Ismail M.M. Rahman, Yoshinori Tsukagoshi, Tomoya Wakabayashi, Teruya Maki, Satoshi Mizutani , Hiroshi Hasegawa, Chemical Engineering Journal 277 (2015) 219–228

[xli] Birendra Babu Adhikari,Manju Gurung,Hidetaka Kawakita,Keisuke Ohto Chemical EngineeringScience78(2012)144–154 Note that the synthesis of cyclic calixarenes is non-trivial.

[xlii] Hiroyuki Miyauchi, Aoi Minozoe, Shigeru Tanaka, Akiyo Tanaka, Miyuki Hirata, Masahiro Nakaza, Heihachiro Arito, Yoko Eitaki, Makiko Nakano and Kazuyuki Omae, J Occup Health 2012; 54: 103–111

[xliii] Xianlai Zeng, Fang Wang, Xiaofei Sun, and Jinhui Li ACS Sustainable Chem. Eng., 2015, 3 (7), pp 1306–1312

[xliv]. Matheson Corporation, Hydrogen Selenide Gas MSDS (Accessed August 8, 2015)

[xlv] Izak Kapilevich, PhD Andy Skumanich, PhD Photovoltaic Specialists Conference (PVSC), 2009 34th IEEE (Proceedings)

[xlvi] Coby S.Tao, Jiechao Jiang, Meng Tao Solar Energy Materials & SolarCells 95 (2011) 3176–3180

[xlvii] T. E. Graedel, E. M. Harper, N. T. Nassar, and Barbara K. Reck PNAS vol. 112 no. 20 pp 6295–6300 (2015)

As always, this was a serious message wrapped in an entertaining presentation. I look forward to reading the comments.

From Wikipedia nuclear reactor control rods are of an alloy which is 15% indium.

According to a US Department of Energy critical materials survey wind turbines use no indium but solar cells do. It is the lanthinide elements for permanent magnets which are of concern. However some wind turbine manufactures don’t use those elements.

Indium is not required for bearings and I doubt it is used for that any more. I doubt indium is essential for detection of wind shear.

@David Benson.

Some nuclear control rods may contain indium, but the physics of control rods is less material dependent than one might think. Indium is not a strong absorber of neutrons, and in cases where it is found in control rods is probably nonessential and related to material properties that can be managed elsewhere..

Cadmium and some lanthanides, often gadolinium, dysprosium, europium or samarium are also found in some control rods.

In the case of samarium, its accumulation as a non-volatile fission product is partially responsible for the shut down of current commercial reactors before the fuel is fully consumed. This suggests fissiogenic samarium (and indeed europium) as a potential source of control rod material. Truth be told, the types of reactors about which I often think are not dependent so much on control rods as they are on physical manipulation of the fuel. Although the fission yield of europium is relatively low, this is also possible for europium. Under conditions in which it is used as a neutron absorber, some is transmuted into gadolium.

I’m a big fan of utilizing fission products, and in fact, actinides, by putting them back into reactors.

In all cases, the high energy to mass density makes these types of concerns far more trivial than with so called renewable energy.

I agree that indium bearings are probably not essential, any more than indium solder (not mentioned in the text) to build wind turbines. In the first case, I included this disclaimer in the text. (Indium here, is in any case, is a surrogate threatened element in any case.)

However, if one googles “LIDAR” and “Wind turbines” one will get around 68,000 hits. This technology is clearly involved in some wind turbines. It does not mean that wind turbines without LIDAR are not built or that the wind industry cannot exist without them, but clearly the LIDAR systems have been included to address a need. The reference provided – there are quite a few actually – indicate that indium inclusive ceramics are, in fact, utilized in LIDAR systems. My overall point is that given that wind turbines have relatively short lifetimes, any attempt to eliminate LIDAR type technology – whether indium based or not – which almost certainly is included in addressing the poor lifetimes of wind turbines. If such technology is unavailable, so might the effort to make them last for decent periods be unavailable.

Thanks for your comment.

NNadir, how much indium does LIDAR require? I’m pretty sure it’s nowhere near the 1.21 kg per turbine that you mentioned last time.

While I checked that figure, I also happened to notice that you’d said “The mean age of operating Danish wind turbines is 15.25 years, 15 years and 92 days” and “Of those that were decommissioned, the mean lifetime was 16.94 years (16 years and 310 days)” which means you’re seriously misrepresenting it when you say “that historically wind turbines remain operational of a mean period of about 15 years”.

Hi NNadir,

Thank You for great perspective on unreliable energy sources from the point of view of fellow chemist. I’m impatient for the third and further installments. I hope that You will discuss the claims that Uranium in seawater is saturated and therefore extracting it would only result in same amount of it leaving oceanic muddy bottom (seen it many times but never properly references/explained). If it is so then this route for obtaining Uranium is even more attractive for, well convincing sceptics about wonders of nuclear energy (and current PWR/BWR fleet), not that U is in short supply from other sources thought.

I would like to see this topic addressed with research quality(references, numbers) that You put in writing this series, as well as other blog essays of Yours.

Keep up good work!

msxc

Nnadir

Indium in Lidars are not crucial for their function but just one of many possible photo sensor options available to the producers of Lidars. Lidars are however very important for wind turbines and especially wind farms.

Lidars on individual wind turbines serves to measure the speed of the oncoming wind and adjust the pitch of the blades and the yaw of the nacelle in advance of sudden gusts or wind direction changes.

Lidars covering entire wind farms serves to measures the wakes after all the wind turbines and optimize the yaw and pitch of all the wind turbines in the wind farm to increase the total output as well as to limit stress upon wind turbines that are showing signs of beginning component breakdowns. The research in this field is ongoing and it is expected that the LCOE for wind farms will be improved by approximately 3%.

Lidars covering large areas are also now beginning to be used to map wind resources, which can be an important cost saver by siting optimization and hub height adjustment.

Lidars for wind turbines track small dust flakes in the wind and works just like any other range finder except it also calculate the trajectory and speed of the flakes in the wind. In this article it is described how Lidars are used to give planes forewarning of turbulent air, which may save lives. http://science.howstuffworks.com/hidden-threat-in-the-skies-info12.htm

Without knowing the numbers I will assume that the indium used for Lidars in the wind industry is a tiny fraction of a percentage of the indium used in Lidars anybody can buy over the counter or over the net.

With that said I totally agree that the wind industry should wean itself of overuse of materials in general and in particular should refrain from using materials in short supply if possible.

In a few years wind power producers will most likely be able to procure Indium free Lidars just as there is no absolute must for rare earth elements in modern wind turbines.

David Benson

Indeed as of 2013 there was use for Indium in bearings for wind turbines. http://swissmetal.net/physical-indium-prices-climb/

Indium coating on bearings is mainly used because it helps spreading lubrication evenly and is especially used in high speed motors. http://education.jlab.org/itselemental/ele049.html

I expect that Indium coating on bearings will be phased out in the wind industry because bearings are now shifting to ceramic bearings. SKF is a major supplier for the wind industry and they market ceramic bearings with extended lifetime. http://www.skf.com/us/products/mrc/hybrid-ceramic-ball-bearings/index.html

@MSXC:

Thanks for your kind words.

Part 3 is largely written, but probably, as is the case with part 2, which was also written, I will edit it and embellish it.

I have collected and included many references to uranium fluxes, albeit primarily from river recharge. It seems likely that this uranium alone would be sufficient to provide 6 or 7 hundred exajoules per year of primary energy indefinitely. Fluxes from undersea volcanoes, or remobilization of sediments are more difficult to quantify, although I did suggest an approach, examining the disequilibrium between U-238 and U-234 in the note/reference 26. (Barry utilized Roman numerals when publishing the document.) I hope you’ll approve of these references, such as they are.

I don’t think anyone here is happy about climate change, but it’s worth noting that uranium is complexed to carbonate in the oceans, and it follows that the rise in carbonate levels suggests a rise in uranium concentrations in the oceans. The solubility of uranium is also dependent on an oxidizing environment. Before the rise of oxygen in the planetary atmosphere, there was very little uranium in the ocean.

I have not read the entire Krishnaswami and Cochrane monograph referenced as 26 – just delicious excerpts – but I do have a copy in my electronic files. If you’re interested in this issue, it’s an excellent resource. You can dig these facts out of lots of papers if you have access and time, but the monograph has everything all in one place. It’s relatively recent, a great resource.

I’ve kind of known a fair bit about the geochemistry of uranium for quite some time, so writing Part 4 was more fun for me than part 3, since one reason I write is to learn. I’ve now learned quit a bit I didn’t know about lanthanide geochemistry. In general, I’ve tended to be aware of the chemistry of lanthanides only from lanthanum to europium, with a little gadolinium thrown in, since they are fission products, and their separation from their actinide cogeners, at least from americium onward is an issue. It’s still a challenge to get lanthanide free curium.

Now I’m learning all about dysprosium, definitely a cool element and one about which I didn’t think much previously.

My training and the early part of my career was more oriented toward organic chemistry, which as a practical matter involves very little solid state chemistry beyond, say, polymorphs, and stuff like that. Another thing that’s been fun about Part 4 is that it’s called on me to understand the beauty and subtleties of solid state chemistry. I’ve been heading this way in any case for a number of years because of my new interest in materials science, but the physical solid state chemistry of magnets is, well, fascinating. I hope I’ll be able to pull that part off credibly.

Thanks for your comments and encouragement.

The main potential use for indium for wind power that I can see is for lead-free solder. That’s really easy to replace if indium is in short supply.

Jens, you write that “there is no absolute must for rare earth elements in modern wind turbines.

The thesis of the author of this series seems to be that renewable/”so-called renewable” electricity (pick your own label) sourced from wind cannot meaningfully be developed at a scale where it can reasonably contribute to addressing emissions and development issues, in part because of issues of materials i.e., they use too much (compared, e.g., with nuclear), and they don’t last long enough (are thus oversold). Indium seems to be used as an example. Your point seems to be that such issues are trivial, or at least readily solvable and already being solved, so the thesis is wrong. (Full disclosure: this is my inference.)

For purposes of advancing the discussion, can you identify the “modern wind turbine” models that do not use rare earth elements, along with their market share and capacity factor? My search could not find these.

Frank Jablonski

http://www.enercon.de/en-en/1337.htm

There are several other proven generator technologies that are absolutely rare earth free. The most researched trend is to use Switched Reluctance designs, that are very well-known as electrical motors but there are several other generator designs that are rare earth free. There is also absolutely no necessity for any other scarce resources. Currently the use of scarce resources is simply economically convenient for the wind power companies.

I wish they were more conscious about the harm that their current praxis are but I suppose they are more concerned about cost than about contributing to a less polluted earth at the moment.

Siemens has opted for a strategy where they from now on only source rare a earth from Molycorp which is a US company that presumably operate under US legislation regarding pollution and

the security of the work force.

Greg

Indium in soldering is used in various industries but I assume everyone would do their outmost to limit or avoid such a costly material in soldering.

The solder I buy certainly does not contain Indium. I doubt if wind turbines requires Indium containing solder. If you can dig deeper and find reference to Indium solder and potentially also find out the benefits of using Indium containing solder, I would read it with interest.

Hi NNadir,

I’m a little bit surprised by your harsh comments against the now inactive blog, theoildrum.com. Your portrayal of the site would give one the impression that it was some sort of Greenpeace anti-nuclear blog run by Amory Lovins, which is not the case at all. Indeed, you found all sorts of people posting there, including some very experienced engineers, many of whom had worked in the petroleum and nuclear industries. I gained a huge amount of technical knowledge from reading their posts, and it was great to be able to ask questions (and get answers) from people who were experts in their field.

To be sure, the greenies were there, advocating such “solutions” like making your own methane at home from pig shit, or cooking your dinner by wrapping it in aluminum foil and attaching it to the tailpipe of your car so you could cook while you commuted. Fortunately, those types of posters were few in number, and were often rebutted by more enlightened individuals who would, for example, point out that wasting aluminum foil on tailpipe cooking probably consumed more energy than was “saved” by not cooking dinner on your stove.

It was at The Oil Drum where I met nuclear engineers online who explained such things as the IFR, or why a liquid thorium reactor was a technology worth developing. Overall, my experience on The Oil Drum made me far more pro-nuclear than I ever was before.

Cy: I made it pretty clear that I wasn’t a regular reader of “The Oil Drum.”

I’m sure that there were fine people writing there, and I remarked that I found at least one of them, “Glenn,” to be quite witty. I note that I found him witty not because of his remarks on Amory Lovins were positive, but because they contained a healthy does of sarcasm.

This said, I also made my objections to what I regard, on the part of some – clearly not all – “peak oilers” – is the attitude that life as we know it would end without oil. If you consider it, you will see that my criticism was really not of the web site (which I’m not qualified to judge since I really wasn’t into it), but about the attitude of people like James Kunstler who may or may not have posted there. I believe that this “oil is essential” attitude has resulted in great tragedy. I object to the dystopian fantasy that represents a subset of “peak oilers” that we are doomed without oil, that we’ll all go back to primitive times.

I have encountered “peak oilers” in various places who extend “peak oil” analogies to “peak uranium,” “peak this,” “peak that.” There are times that “peak this” and “peak that” arguments can have merit – I think I have tried to make the case for indium – but there are clearly times that they are expressions of hopelessness, a conservatism that insists that everything must be done in exactly the same way it has always be done or everything will fail.

Uranium is inexhaustible. That much is clear.

I’m not about, in any case, to withdraw my criticism of Ugo Bardi, the peak oiler academic at the University of Florence. I will expand on this criticism in Part III. He’s been very sloppy in his remarks on uranium. Interestingly, the current issue of Environmental Science and Technology has a thematic examination of “critical element” flows, and one of the papers addresses minerals from seawater, citing Bardi. I may find it possible to have some fun with that.

Oil was probably a great transitional fuel. With clear thinking, we might have begun to have phased it out in the 1970s. It is technically feasible – maybe not politically feasible, but technically feasible – to be done with it. It was technically feasible in the 1970’s and if one looks, one can understand that some people got it, not the majority perhaps, but some.

For the record, I often – almost always – use the adjective “dangerous” when referring to oil and/or coal and natural gas. What we have run out of is not oil, but places to put oil waste. The solution to our oil problem is to leave as much as is possible in the ground.

I hope this clarifies my remarks, and I apologize if I’ve offended you.

As a contributor to the now-inactive blog theoildrum.com, I can say with assurance that it was a camp of wildly-differing positions held together by nothing—as a matter of fact, rather vicious censorship was often used to keep some contributors from expressing their full opinions of the positions (and honesty) of others.

As did I. Often censored by the “tone police”.

He didn’t, though he was referenced many times.

Yes, I debated ones such as Gail Tverberg a number of times on that. She believes that many things become impossible without petroleum, ignoring how those things were done BP (Before Petroleum). You can’t get through to some people.

Well… on a scale far beyond the endurance of human civilizations, at least. I don’t see what’s to worry about beyond that.

I see this to the present day (the staff mailing list of TheOilDrum is still active, and I’m on it). The positions are hard. But I think Francois Cellier (evidenced by his protegé was harder than Hugo.

FWIW I read Kunstler’s book The Long Emergency, and while he was overly pessimistic, he did note that to mitigate the problems of running out of oil we should build nuclear power & electric rail.

Count this as a lukewarm defense of him for seeing what should be obvious to anyone who thinks about the issue, though many do not.

I can’t say that I know who Francois Cellier is; I probably don’t want to know; it’s bad enough that I know who Ugo Bardi is.

Ms. Tervberg, I’ve encountered. I used to comment and sometimes post at the Energy Collective and one of my last comments in that space actually involved a…um…um…um…would “insipid” be too hard a word?…comment she made about nuclear power.

I quote her:

“My concern about nuclear is the issue of whether they can be safely operated in a world that is falling apart for other reasons-a financial system that is breaking; a system that provides too low a price for oil, natural gas, coal, and electricity.

In such a system, safeguards that we have been used to, including the availability of electricity going into a nuclear power plant may be lacking. The ability to pay workers may disappear. The ability to keep electrical transmission lines repaired is likely to decline over time, making electricity from nuclear less and less useful. The ability to decommission such plants will disappear, cleating a much higher hazard for nuclear waste problems. These plants have only a 60 year or so lifetime. They require fossil fuels to build, so it is unlikely that we can build replacements.”

http://www.theenergycollective.com/gail-tverberg/588571/low-oil-prices-sign-debt-bubble-collapse-leading-end-oil-supply#comment-156976

I mean she’s predicting that the whole world is going to fall apart – I’d guess she means without oil – and the big concern, the over riding concern is that nuclear power plants will be a problem.

It would be more enlightened of her to engage in some consideration of the number of people who have died from uncontrolled oil waste, not to mention oil based accidents, not to mention oil based terrorism, not to mention oil based wars, not to mention wars caused by oil (World War II qualifies), and not to mention oil diverted to weapons of mass destruction.

But no…she’s worried that we need oil or we’ll all die.

Like I said in the text, I haven’t really spent all that much time on “peak oil” stuff or hanging out with “peak oil” people, probably because some of those I have encountered or read all had the logic that Ms Tverberg demonstrated in that post:

“The world is ending, because we’re out of oil but never mind that, let’s worry if nuclear plants are safe!?!!?!”

;-O.

You can’t make this stuff up.