So far in the IFR Facts and Discussion series, I’ve discussed Gen III and Gen IV fuel cycles and energy densities. In later IFR FaD posts, I aim to explore some possible scenarios for future deployment of the IFR and related technologies. But before I can do this, I need to explain (and justify!), some key underlying concepts — fissile inventory (what Alex Goodwin cleverly called the nuclear ‘spark plug’ in this post on the LFTR), breeding rates, and available fissile and fertile stockpiles. But before I even do that, I should give you the ‘vision thing’.

So far in the IFR Facts and Discussion series, I’ve discussed Gen III and Gen IV fuel cycles and energy densities. In later IFR FaD posts, I aim to explore some possible scenarios for future deployment of the IFR and related technologies. But before I can do this, I need to explain (and justify!), some key underlying concepts — fissile inventory (what Alex Goodwin cleverly called the nuclear ‘spark plug’ in this post on the LFTR), breeding rates, and available fissile and fertile stockpiles. But before I even do that, I should give you the ‘vision thing’.

———————————

After allowing for the benefits from improved energy efficiency, I estimate the world needs to generate roughly 10 terawatts (10,000 gigawatts) of electricity as “clean energy” worldwide by 2050 – a five-fold increase on the energy used today. The world’s current nuclear power capacity, amounting to 380 gigawatts of electricity, has been built up over 50 years. The goal of 10 TWe by 2050 would require a rate of building some 30 times faster. Is that even remotely possible?

To have any realistic chance of achieving this goal — which we must, for the sake of climate change mitigation and peak oil-related energy security — we will need to expand global nuclear power capacity as rapidly as possible over the next 20 years. The most feasible way to do this is by constructing a fleet of generation III+ reactors, such as the AP-1000.

Integral fast reactors and liquid fluoride thorium reactors have so far operated successfully only as demonstration plants and experimental reactors. Nevertheless, a 500-megawatt (0.5 gigawatt) fast reactor is to become operational in India during 2010. Some commercial “generation IV” units have been operated (such as the Phenix fast reactor in France and the BN-350 and BN-600 in Russia) but only a few are currently being built. This is largely because uranium is still plentiful and cheap. That means there is insufficient incentive to invest in this “leap” technology, despite its advantages. Even so, construction is about to start in Russia and China on three BN-800s, scheduled for completion within five years.

Integral fast reactors and liquid fluoride thorium reactors have so far operated successfully only as demonstration plants and experimental reactors. Nevertheless, a 500-megawatt (0.5 gigawatt) fast reactor is to become operational in India during 2010. Some commercial “generation IV” units have been operated (such as the Phenix fast reactor in France and the BN-350 and BN-600 in Russia) but only a few are currently being built. This is largely because uranium is still plentiful and cheap. That means there is insufficient incentive to invest in this “leap” technology, despite its advantages. Even so, construction is about to start in Russia and China on three BN-800s, scheduled for completion within five years.

As a significant number of generation IV units start to come online over the next few decades, they will need fissile “start charges” to kick them off. A new 1 gigawatt fast spectrum reactor, for instance, needs to be fuelled with about eight tonnes* of fissile uranium 235 or plutonium (or some other mixture of fissile actinides) to get it going. After that, it can breed all the new fuel it will ever need from uranium 238.

Yet, if all of the world’s stockpile of weapons material and used nuclear fuel were reprocessed, we could still produce only enough fissile material (about 3,000 tonnes) to launch just 400 1-GWe fast reactors in the decade 2020 to 2030. After that, if nuclear power is to continue to expand at a rapid rate, we would need a reactor deployment program where we continue to build both generation III and generation IV units for the next few decades.

This program would see the spent fuel from light water reactors reprocessed for use in fast reactors, and new fissile material bred from fertile uranium 238 or thorium 232 in fast reactors. It would take about eight years of breeding** for a fast reactor to create enough new fissile material to start another reactor of equivalent size. (This is called the “doubling time” because the original fast reactor would also continue to operate.)

Only in this way can we achieve the world’s growth path to 10 terawatts (10,000 gigawatts) of nuclear electricity by 2050.

———————————

In the above statement, there are two asterisked sections of text. The justification for the figure of 8 tonnes of fissile per GW, and years doubling time is really important, but I don’t want to get into the debate about that in this thread. I’ll be happy to argue these figures until I’m blue in the face in IFR FaD 6 & 7, so please hold fire until then.

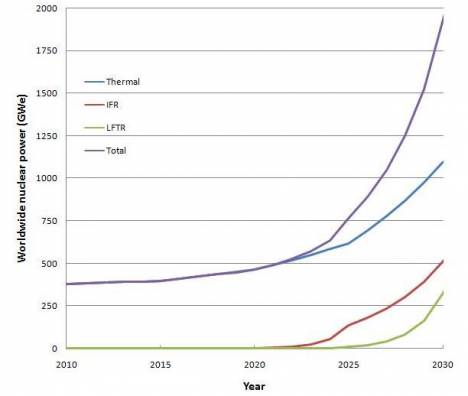

At a recent uranium conference, I presented a forecast for at least a quadrupling of the thermal reactor fleet (gen III) over the next 25 years, to ~1,500 GWe by 2035. I’ll talk more about this projection, and the possible extent and technology mix of the gen IV component, in IFR FaD 9 (#8 will be a brief digression on short- and long-term nuclear fuel supply). The chart above is a teaser…

At a recent uranium conference, I presented a forecast for at least a quadrupling of the thermal reactor fleet (gen III) over the next 25 years, to ~1,500 GWe by 2035. I’ll talk more about this projection, and the possible extent and technology mix of the gen IV component, in IFR FaD 9 (#8 will be a brief digression on short- and long-term nuclear fuel supply). The chart above is a teaser…

Way back in May 2009, I kicked off a discussion thread on BNC called “Should Gen III nuclear power precede Gen IV in Australia?“. It’s interesting to look back at the responses, and reflect on my evolved position. Back then I was uncertain whether Gen III was needed. Why not leap ahead now? More than a year later, I am still consumed by the urgency to get Gen IV going, but Gen III is now certainly also my trusted ally. To explain, let me quote some colleagues of mine from SCGI (we have regular correspondence via a private Google Group).

[The term LWR = light water reactor, that is, gen III thermal reactors (along with heavy water reactors, e.g. CANDU), like the kind now being built by the dozen in China; NRC = US nuclear regulatory commission; S-PRISM = prototype IFR, 300 MWe module; 4S = Toshiba’s nuclear battery (also a sodium-cooled fast reactor)]:

Ray Hunter: “What this country needs now is NRC’s full time attention to get new LWR’s through the process. In addition, industry needs to place many more real licensing requests for LWRs so the country [the US] can begin to make an orderly transition from coal to nuclear. If the government’s mishandling of the waste issue continues to be a deterent for private sector investment for LWRs then we need to proceed with a demonstration facility. When you consider the cost of the waste management i.e.Yucca Mountain, treatment facilities to prepare the material for use in future S-PRISMs can be economical if the private sector becomes the lead as suggested by the new proposed legislation. In summary; A) MANY new LWRs, B) recycle demonstration; C) S-PRISM demonstration”. We could proceed with a IFR demo plant today but we would be missing a key facility required to deal with the LWR waste issue. This is the facility that Yoon has pushing for to demonstate we can convert LWR spent fuel into metal fuel for the IFR. Until this conversion facility is operational, it doesn’t make sense to have a face off between LWR and IFR because the IFR will lose every time. Forget the end of the world strategy, it doesn’t sell.

Bill Hannum: “What we need now for power is many LWRs. In addition, we need to demonstrate the feasibility of efficient recycle in fast reactors, to show that we have a solution to the nuclear waste problem, and a means to utilize essentially all the energy content of the uranium, when and if we need to do this. We do not need a lot of fast reactors now; the LWRs will carry us comfortably for a number of decades. But the political, and public perception that there is no solution to the nuclear waste problem can be removed by a simple demonstration of efficient recycle. The economics can be evaluated after we demonstrate the operational feasibility of such a system. This is laid out in my papers in Tom Blees’ SCGI web site. Disputes as to whether 4-S of S-PRISM or traveling wave reactor is at best a distraction from the need to demonstrate multi-pass recycle in a fast reactor. The key is LWRs now, and demonstrating recycle technology, not the [short-term] transition to a fast-reactor based economy.”

Dan Meneley: “The right path is to build A LOT of thermal reactors right now, quickly, and then move to the IFR. If humanly possible, the thermal reactors should have a high internal conversion ratio. Then the FBRs (aka SFRs) can be brought in as the uranium and thorium prices start to get out of control (as we see happening now with oil). We need to recognize just where the centre of gravity is right now — it’s with the LWR — and plan the IFR program so that it eventually wins, instead of being stamped to death by those nasty and brutish LWR proponents. Saying that “in the end” the IFR will dominate is no solution. It is like saying that a wonderful life awaits us, if we will just stop breathing for a day or two.”

———————————

There’s plenty more discussed within this group on this issue, but you get the gist. We need Gen III, and we’ll need Gen IV. Time to start considering the pathways for getting both of them through and past the current bottlenecks.

.png)

Barry,

Yes, we need the LWR spent fuel for it’s fissile material and it can start up a fleet of LFTRs, which require less fissile material than IFRs. Here’s a snippet from a draft of an article in the next American Scientist.

Radioactive waste

LFTR reduces nuclear waste storage issues from millions of years to a few hundred years. The radiotoxicity of nuclear waste arises from two sources: the highly radioactive fission products from fission and the long-lived actinides from neutron absorption. Thorium and uranium fueled reactors produce essentially the same fission products, whose radiotoxicity in 500 years drops below even that of the natural uranium ore to power a PWR. LFTR creates far fewer transuranic actinides because Th-232 requires 7 neutron absorptions to make Pu-239, whereas U-238 requires just one. After 300 years the LFTR waste radiation would be 10,000 times less. In practice, about 0.1% of the LFTR transuranics might pass through the chemical waste separator, so the LFTR waste radiotoxicity would be 1/1000 that from LWRs. Geological repositories smaller than Yucca mountain would suffice.

Existing PWR spent fuel can be an asset. A 100 MW LFTR requires 100 kg of fissile material (U-233, U-235, or Pu-239) to start the chain reaction and the neutron flux that converts fertile Th-232 to fissile U-233. The world now has 340,000 tonnes of spent LWR fuel containing approximately 3,400 t of fissile material, enough to start one 100 MW LFTR per day for 93 years.

In summary, LFTRs will produce < 1% of the waste of LWRs and also consume the long-lived fissile materials in existing spent fuel.

Many problems with fast reactors would be solved if they are used for thorium cycle as well as uranium cycle breeding. This is exactly what the Indians plan to do. The Indians also plan to do this starting next year. Metal cooled fast reactors are at least 10 years away, and possibly longer. Fuel reprocessing is still going to be expensive, and there will quite possibly a plutonium loss problem. It does not make a whole lot of sense to fish fuel out of a reactor, and then dissolve it in a molten salt solution and then take it back out. melt it down into fuel rods, and then insert it back it back into the reactor. A better idea would be to dissolve uranium and plutonium chloride salts in a carrier/coolant fluid of other chloride salts, and use MSR technologies including MSR fuel reprocessing technologies like distillation. This would make fuel reprocessing a whole lot easier, and liquid chloride salts are a whole lot safer than liquid sodium. The idea was first thought of in Oak Ridge, so i guess that solution wont fly with the ANL crowd.

The perspective is one that I”ve advocated here as well, Barry. I also advocate it within Ken’s LFTR forum as well…that *all* future Gen IV technologies are tied to the success of Gen III. They are not counterpoised and while representing very different approches to fission and all this implies, they bound by hips in their long term success, which I think you articlulate well, here.

At any rate…we are going in that direction iat any rate.

There are substantial 3-way synergies between Gen III plants, IFRs and LFTRs, particularly if the Gen IIIs are CANDUs and derivatives or you put some thorium in their fuel. There is a paper from the French MSR group discussing this. Last time I posted about this it started a most uncivil discussion on energyfromthorium, but judging from the graph above, Barry read it, or derived a similar result.

Thanks Luke, yes, I’d read the French paper — it’s also listed as a ‘to read’ on the SCGI site, and it helped shape my thinking. I believe some of their calculations are incorrect (actually, I should say, I disagree with some of their assumptions – including about build rates), but the thrust of the paper is good and it’s definitely worthwhile reading. Thanks for the reminder/link.

This looks like the only viable path to take at present, unless of course we want to build dedicated Pu breeders à la mode de le Cold War. The French paper tiptoes around this basically by making the Pu breeders generate power as well, but in my view this will likely be seen for the fig-leaf that its.

The problem here is not the technology, but the politics. Any cycle that involves the production of Pu is going to draw fire from several quarters and this will probably be the biggest issue that will need overcoming.

The other issue is the uranium supply. While historically mineral availability estimates have been poor indicators of what is really accessible, (RAR* figures not withstanding) the fact remains that the market has been seriously distorted by the introduction of ex-weapon fissile material. This has led to a much reduced rate of prospecting and opening of new sites and has inhibited the development of new mining techniques that will be needed to exploit a greater range of deposits.

Thus it may be that to meet the target of 10 terawatts, a much more aggressive program will be needed.

*RAR = reasonably assured reserves – normally a conservative figure, based on the output worked mines.

Well reasoned post – thank you; I look forward to the remaining parts of the series.

Also very good to see focus on the reprocessing of thermal fuel for GenIV. In my view this is the key component that can persuade most folk to aggressively adopt nuclear.

If we cannot show an economical way to reduce the gen III waste half life to manageable proportions we should not do this thing.

Barry, I have today posted an account of India’s long term Generation III+ and Generation iV development programs. The Indians view the development of advanced Generation IV and Generation III+ technologies as complimentary, and are planning to use large numbers of Generation III+ reactors well into the 21st century,

Thanks Charles, for reference to BNC readers, the link is here:

http://nucleargreen.blogspot.com/2010/06/indian-long-term-nuclear-development.html

India are clearly developing as THE world leader in both the rapid commercial deployment of fast reactors, and with the best-planned strategy to capitalise on the Gen III+ to Gen IV synergy. They also have a lot to gain — perhaps more than any other nation — in making the thorium cycle develop into a seriously economic and scalable prospect.

Barry,

I suspect Australia has plenty of Thorium too. We just haven’t gone looking for it yet. I have no basis for this statement other than the average concentration of thorium is about 3.5 times the concentration of uranium i the Earth;s crust.

Average concentration in the Earth’s crust, in ppm, of Thorium and a few other elements:

Th 9.6

U 2.7

Sn 2.0

Ge 1.5

Mo 1.5

Peter at 9.6 PPM thorium is recoverable with a positive ERoEI from LFTRs. There are of course many attractive thorium sources with far higher concentrations. Rare Earth deposits are often associated with high concentrations of thorium.

Something that will have to be considered here is the materials issue. It is all very well to build a demonstration plant and run it for a few years, but a commercial plant will have to have a reasonable life expectancy, and material selection is a large factor in achieving this.

The core of a nuclear reactor is where the fuel is located and where nuclear fission reactions take place. The materials used to encase the fuel in fuel rods, to hold fuel rods together in fuel assemblies, and to hold fuel assemblies in place are all considered ‘core structural materials’, as are the materials used in control rods and core monitoring instruments and their supporting structures, this includes the materials of the first wall and blanket chamber (if present.)

The core structural materials have to retain their functionality to maintain integrity of the fuel rods and fuel assemblies, preventing release of radioactive materials from the fuel to the coolant. To support higher burnups, improved radiation resistant materials need to be developed that can withstand harsher irradiation environments and higher temperatures.

Materials behaviour under irradiation has been studied for more than 50 years, with most experience in thermal reactor materials. Some experience has been acquired in the area of ‘fast reactor materials’, but the high temperature reactor (HTR) area is much less explored.Materials to be used for Generation IV reactors and future fusion reactors will operate at even higher temperatures 500ºC–1000ºC.

The lack of high temperature neutron sources is going to make the search and qualification of new materials very difficult. Thus one of the first steps must be to build such a facility , or we may be learning some very expensive lessons in the field.

DV82XL. Good point. It’s going to take longer to get to commercial Gen IV than many people think.

Charles Barton, Yes, I should have made it clear that the figures I gave are the average concentration of these elements in the Earth’s Crust. All elements are concentrated in some places. When the concentration is high enough, and the element is in sufficient quantity, it may be economic to mine. What I was trying to point out is that mineral exploration has only scratched the surface – and not much of it – yet. On this basis there will be lots of thorium in Australia too. We just haven’t found it yet. There has been little incentive to look so far.

The materials science for the SFR has been worked through systematically over many decades, and is much better understood, and tested, than your comment might imply DV8. It is more than ‘some experience’. The EBR-II alone ran for 30 years, and there is further experience (in just the US) from the FFTF, FERMI I, EBR-I and so on. The outlet temperature for an IFR would be ~530ºC. Peter, I don’t think your first sentence is therefore justified – at least not for the most mature of the Gen IV technologies. I would not even class fusion reactors as Gen IV — they are Gen V, or beyond.

I was not trying to imply that fusion is a GenIV technology – an artifact of my poor grammar only, I assure you.

However, I don’t see the materials issue as solved in any way as yet for high temperature, high neutron flux reactors. I have followed this area for some time, and while good work has been done, it is not just a simple matter of performance, as is in fact the case for material selection in any technical domain. Issues like cost, difficulties in fabricating, scalability, availability and other similar questions have not all been answered

While the results from the work done with EBR II are encouraging the fact remains that this reactor was only rated for about 65MWt, and it simply not the case that material performance scales well or even linearly. Consider wood, which is an excellent material for marine and aviation applications up to a certain size, and then becomes unusable above.

At any rate I was not suggesting that these reactors not be constructed. I was pointing out that development facilities should be built now to explore this regime, rather than assuming that all the preparatory work has been done in this area. The EBR II was one of those facilities, as was the Fast Flux Test Facility. Unfortunately, while much was learned, I’m not convinced that the materials issue was closed, and another such reactor is needed.

That was the thrust of what I was trying to say.

Barry,

I do think your article is really excellent and thank you for it.

I don’t have much knowledge of Gen IV. However, I come at the Gen III/IV in Australia issue from a different perspective. I see how long it takes any technology and any industry to mature. We are 40+ years into Gen II and Gen III and they are still having major design changes (EPR, AP1000, and the latest changes that are being required to both). They are very costly in part because of these ongoing design changes and ongoing changes in requirements. We only need to read the discussions on this web site to realise just what an early stage of development the Gen IV is at. I watched the progress of Synrock. And the CANDU’s had problems with pressure tubes splitting around 20 years into their life. Most of the early versions needed major refurbishments as a result. So on this basis, my gut feeling is we have many decades to go before Gen IV is a commercial proposition for Australia. Ziggy Switkowski says 2030 at the earliest and I accept that.

I also believe that Australia cannot lead in this. We can talk about what other countries are doing, but right now our focus should be in removing the barriers to Gen III. We’ll get to Gen IV when it is commercial.

I have been advocating for some time that Australia start funding the universities and research orgnisations to work out hoew to get nuclear power established in Australia at least cost and soon. If we get too involved in Gen IV I forsee that our research establishments will put too much of their effort into Gen IV since it is the exciting new horizon for researchers.

If we divert a significant proportion of our attention to explaining Gen IV now, we are spreading our effort and adding to confusion. IMHO.

I understand what you are arguing, but I still feel our effort would be misdirected if we focus too much on Gen IV.

ps. As DV82XL says, commercialisation of technologies is a very long, costly and high risk process. AECL had the Oil cooled reactor at Whiteshell, the SlowPoke reactor, a nuclear battery and others. The never became commercial. The oil cooled reactor at Whiteshell was claimed to be far superior to the CANDU but AECL couldn’t afford to commercialise it. They’s sunk too much money into the CANDU (so I ujnderstand).

Peter Lang, on 12 June 2010 at 8.30 Said:

WR-1 operated for twenty years as a test bed for organic coolants, and carbide fuel, as well a neutron source for other experiments. The CANDU-OCR that was to be designed from the work done there was cancelled simply because at the time the advantages of that design over the CANDU-PHR were marginal given the cost difference.

Now however a reactor with over double the burnup rate and a ~450C outlet temp would have a market in the Oil Sands and there is some talk of reviving the idea, WR-1 also burnt test thorium fuel bundles at very improved rate compared to the standard CANDU

The SLOWPOKE series was a very successful little reactor, and several were built. It is the only reactor ever licensed for unattended operation. It was such a good design that the Chinese started making and selling an exact knock-off of it to several countries calling it the Small Neutron Source thus killing AECL’s export market.

The SLOWPOKE III, which was to be a district heating reactor for communities in the North, was cancelled after things settled down from the first oil crisis, and it was no longer competitive.

I would really be interested in what the relevant folk in SCGI say in response to DV’s comment about the “materials issue.”

DV82XL, Thank you for that info. I didn’t know that China had copied SLOWPOKE and killed off AECL’s market.

This highlights the enormous commercial risk involved in developing new technology. It points out the problems that commercial firms would have with developing Gen IV designs and taking them through to the stage where they are fully commercial. This supports my argument, that it is going to be a long time until Gen IV is an option for Australia. I hope USA, France, Russia, China, India and Korea will continue RD&D, and Australia should be a part of any cooperative international effort. In the meantime, I believe we need to focus on how we can get nuclear started in Australia. I believe the focus needs to be on implementing nuclear in Australia in a way that will give us least cost electricity over the long term. That should be our primary focus. We need to keep it simple like that. When people ask questions about safety, nuclear waste, proliferation, etc, we can answer those questions, but let’s just get a really simple objective:

to implement nuclear power in Australia in such a way that it will supply electricity at the lowest possible cost over the long term.

I’ve written this here on more than one occasion and been answered by [crickets] so now I’m going to shout:

YOU GUYS ARE SITTING ON 25% OF THE WORLD’S KNOWN RESERVES OF URANIUM. MANY OF YOUR ASIAN TRADING PARTNERS BUILD REACTORS, BUT HAVE NO DOMESTIC SUPPLIES OF FUEL.

CUT SOME DEALS, FOR PITY’S SAKE

I will put it to them, as I hesitate to debate further on this issue with a materials scientist…

I’m not trying to throw cold water on the idea of Gen IV reactors. It’s only that there is often a lot of considerations that have to be taken into account when you look to develop something like this, and one can’t leave your flanks to God and good luck and hope that you don’t run into problems.

Four or five years ago, there was great excitement over molybdenum-rhenium alloys for core structural materials until it was found that under certain conditions transmutation was leading to precipitation and segregation that was unacceptable,

On the other hand two composites types are being developed for incore application: carbon fiber carbon composite (CFC), and silicon carbide fibre composite (SiC/SiC.) Irradiation effects studies have been carried out over the past few decades yielding radiation-tolerant CFC’s and a composite of SiC/SiC with no apparent degradation in mechanical properties to very high neutron exposure. So ceramics might come through for us.

The point is that there (IMHO) not enough work being done in this area, because of a dearth of high-flux reactors, and this is not a good thing.

Correction: My son correctly points out that the Chinese knock-off of the SLOWPOKE is the Miniature Neutron Source reactor not the the Small Neutron Source as I stated above

Four or five years ago, there was great excitement over molybdenum-rhenium alloys for core structural materials until it was found that under certain conditions transmutation was leading to precipitation and segregation that was unacceptable,

DV: Please translate meanings in a materials context of “transmutation,” “precipitation,” and “segregation.”

g

[…] IFR FaD 5 – the Gen III and Gen IV nuclear power synergy – why we need both So far in the IFR Facts and Discussion series, I’ve discussed Gen III and Gen IV fuel cycles and energy densities. In later IFR FaD posts, I aim to explore some possible scenarios for future deployment of the IFR and related technologies. But before I can do this, I need to explain (and justify!), some key underlying concepts — fissile inventory (what Alex Goodwin cleverly called the nuclear ‘spark plug’ in this post on the LFTR), breeding rates, and available fissile and fertile stockpiles. But before I even do that, I should give you the ‘vision thing’. […]

In very simple terms:

Transmutation – in this instance an atom changing from one element to another due to neutron radiation

Precipitation – in this instance elements coming out of solution in an alloy

Segregation – the property of these precipitated atoms to clump together with their own kind.

These are concerns because these actions lead to grain-boundary defects that can lead in turn to mechanical failure, due to loss of strength or spontanious cracking.

Some alloys can be treated when this starts to happen by a processes improperly called annealing in the nuclear industry (I say improperly, because they use the term as a catch-all phrase, for several different processes, of which proper annealing is just one) and returned to a serviceable state. Others cannot be short of remelting, and must be scrapped.

There are other considerations like hydrogen and helium sorption that can lead to embitterment.

Again I reiterate: this is not going to stop Gen IV in its tracks – I only bring it up because I don’t believe that there is enough work on going right now on this matter and it is an area that should get more attention.

Look CANDU fuel channels supposedly were proven in the NRX, which was the highest flux neutron source in the world at that time, yet they started to fail prematurely in service after several had been built. They all had to be replaced and this almost killed off the design where it stood. Material issues are not trivial. They can jump up and bite you in the ass when you least expect it.

DV82XL,

Your presence and contributions here are fantastic. I am learning heaps from your contributions and others on your web site.

Barry, I want to say again that the lead article here is really helpful. I’ve just seen this video http://atomicinsights.blogspot.com/2010/04/c-span-studentcam-2010-grand-prize.html and thought “wouldn’t it be great if they had known about the relevance of Gen IV, as you’ve laid it out in the lead article, when they made this video”. Perhaps you could send them you article. I expect they are buried in offers of help, but an email from a Professor in Australia might get through.

I see a general move forward in acceptance of nuclear in USA, UK, and Australia. I believe Australia is approaching a ‘tipping point’ on acceptance of nuclear. Once it reaches it, there will be a substantial change of in the level of public support (or acceptance it is necessary) over a fairly short time period.

I might add that the materials issue may not be as dire for MSR type reactors like the LFTR.

First, core geometry is basically a function of the first wall, and there is no question of core components cracking, swelling, and distorting as would be the case with a solid fuel core.

The first wall itself, (assuming a two-fluid design) would need to be neutron transparent, which of course would mean less damage would accumulate, and it would be in relative pressure equilibrium due to the presence of the liquid blanket, thus suffering less tensional stress, a major plus.

Also, the outer wall would be largely shielded by the blanket, which after all is there to absorb neutrons, and this would mean less radiation damage over any given time. In fact the use of ceramics on the outer wall might well be the way to go, where a fair amount of mass would be inexpensive and could draw on existing metal smelting materials.

The IFR fleet would all have neutron absorbing axial and radial DU breeder blankets, for the first fifty years or so of their deployment, if they’re launched for the purposes of rapidly expanding Gen IV deployment.

Yes, but their cores are more complex because they are solid and are susceptible to failure due to swelling and warpage and cracking of the various elements.

And don’t think I am saying the situation for MSR/LFTR is a done deal ether material wise, only that the suite of problems might not be as large.

The IFR fleet would all have neutron absorbing axial and radial DU breeder blankets, for the first fifty years or so of their deployment, if they’re launched for the purposes of rapidly expanding Gen IV deployment. – Barry Brook

There is a rub. Exactly how high does the breeding ratio have to be before void worth becomes a serious safety problem? Can IFRs safely breed at high enough ratios to overcome their FI handicaps? The papers I have read on the subject seem to suggest that they can’t and that safe IFR breeding ratios may run as low as 1.07 to 1 . If you assert that IFRs can safely breed at higher ratios, where do you find the evidence?

I will provide information in future IFR FaD posts. (By the way, I don’t know what you mean by “void worth” or FI).

Barry, I encountered the term “void worth” in a number of papers on IFR core design.

See for example here, http://www.osti.gov/bridge/product.biblio.jsp?query_id=0&page=0&osti_id=6018181

And here: http://www.osti.gov/bridge/product.biblio.jsp?query_id=3&page=0&osti_id=5300577

David LeBlanc told me that “void worth refers to how much reactivity increases if the entire coolant turns to void. It is given in units of dollars or cents (strangely enough) where 1 dollar means you will enter prompt criticality. I think just about any sodium cooled fast reactor will have a positive void coefficient but there are many techniques to try to lower it (and negative doppler coefficient will usually save things). It is all quite complex because a void in the center of the core is much different than a void at the edge. Also things like how much Americium is present has a big effect. ”

David also referred me to this Power Point presentation.

http://www.neutron.kth.se/courses/GenIV/GenIVsafety.pdf

R. N.Hill states, “the void worth is much larger ($4 to $5) in conventional lFR core designs.”

Janne Wallenius states,” Positive void worth of 3–4 dollars acceptable if a prompt negative temperature feedback of -0.5 pcm/K is available (Doppler, axial fuel expansion).

Positive void worth of 7 dollars may not be acceptable with a Doppler feedback of -0.2 pcm/K.”

Several papers on the Information Bridge discus IFR designers efforts to lower void worth which all appear to also lower breeding ratios.

Look, light water is considered inferior to other technologies, yet it dominates the market for power reactors. This is largely due to the early adoption and heavy development by the U.S. Navy of light water reactors for marine propulsion.

When a market for civilian power emerged, light water had a large head start, and by the time other technologies were ready to enter the market, light water was entrenched. Not only is the LWR used almost exclusively in the USA today, but this type, based largely on technology developed in the USA, is being used for about 80 percent of all the reactors built or under construction in the world today.’’

This happened because everywhere (except in Canada), military issues were the first to be considered In the U.S., in France and the United Kingdom weapons-grade fissionable material was in demand; in the United States naval propulsion was the main application. When these demands had been relieved or were no longer so pressing, civilian power emerged as the main consideration, and the important characteristics of reactors became cost and safety. After a market for civilian nuclear power was established, these concerns remained in the forefront. Very important in the development of nuclear power, though, was the early interest in military applications. The effects which followed from the military’s definition of “best” have been felt ever since.

While perhaps an appropriate decision at the time, it now seems that light water may have been an unfortunate choice.

I see the same thing happening in the drive to GenIV technology in that short-sighted concerns are driving the selection process with little thought to the long term consequences.

There is simply no rush to put GenIV reactors on-line, and doing so without careful evaluation of the consequences of the chosen design will be with us for a very long time.

[…] despite the enormous medium- to long-term promise of Generation IV (as I recently explained, here). This is not idle speculation -– it is already happening in the world’s fastest-growing […]

[…] IFR FaD 5 – the Gen III and Gen IV nuclear power synergy – why we need both […]

[…] fuel cycle. Indeed, the scenario I think to be most likely is TR1, because it fits logically with a synergistic expansion of closed-fuel cycle ‘Generation IV’ technology like the Integral Fast Reactor and/or Liquid Fluoride Thorium […]

I’m perplexed by the advocacy of the IFR. Allow me to point out that a single molten salt thorium fluoride reactor (TFR) with a one inch thick core the size of a conventional reactor could power the state of California. Perhaps more importantly, it is devoid of the potential for a massive release of radioactive material because the fission products are removed on a continuous basis.

Nothing can touch this reactor concept. Conventional clad fuel designs are so many times more limited and expensive.

I am also confused about this whole non-proliferation advantage of thorium? A major component of the Russian warhead inventory is U-233! Seems like a falacious argument.

In closing, it’s possible that a 15 gigawatt reactor with a dramatically smaller and somewhat irrelevant risk of a release of radioactive material for the cost and footprint of one conventional plant may be something that can be sold much more easily and quickly implemented than any other reactor concept.