With regards to Generation IV nuclear fission technology, most of the attention on BNC has been on the Integral Fast Reactor (IFR), for reasons explained in this post, which I quote:

The focus of this series (IFR FaD) is aimed squarely at the Integral Fast Reactor (IFR) rather than other Gen IV designs, such as the Liquid Fluoride Thorium Reactor (LFTR) or Advanced High Temperature Reactor (AHTR). The reason for this is two fold: (i) I’m more familiar with the IFR technology (and I am in regular email exchange with the world experts on this technology, via SCGI and other links), and (ii) LFTR has a strong and welcoming advocacy group elsewhere, and I’d encourage people to go there to ask more questions about that technology … However, I should make it quite clear that I’m not “for IFR and against LFTR” — both 4th generation nuclear designs hold great appeal to me, and I will sometimes consider IFR vs LFTR comparisons in the IFR FaD series, as a point of comparison or contrast.

I think we need to be pursuing the final stages of research, development and commercial-scale deployment of all of these next-generation fission technologies, since it would require such a trivial input compared to the huge investment that will be required anyway in energy infrastructure over the next few decades (>$26 trillion globally by 2030). However, it is nevertheless useful to consider the relative merits of the individual technologies, and I hope to look at this from a number of angles in blog posts during 2012.

For some initial ideas and to initiate discussion, below I reproduce an email exchange on this matter, including aspects of commercial readiness, that was recently posted on the Science Council for Global Initiatives website. The conversation is from three highly experienced nuclear physicists/engineers, Dr George Stanford, Dr Dan Meneley, and Prof. Per Peterson. I’m sure this will stir some debate! (And, as I said, I will have more to post on this in the new year).

I have also added a few hyperlinks to clarify terms that may be unfamiliar to the general reader; please note that the links and pictures were added by me (Barry Brook), not the original correspondents.

—————-

G. Stanford wrote (11-29-10):

We’ll see what others on this list have to say, but in my opinion, Carlsen’s enthusiasm for thorium is premature, to say the least. The ONLY significant advantage a thorium cycle would have over fast reactors with metallic fuel (IFR/PRISM) is its lower requirement for start up fissile. That advantage is offset by the fact that the thorium reactor is at a stage of development roughly equivalent to where the IFR was in 1975 — a promising idea with a lot of R&D needed to before it’s ready for a commercial demonstration — which puts its deployment about 20 years behind what could be the IFR’s schedule. The thorium community has not yet even agreed on what will be the optimum thorium technology to pursue.

I think that thorium should indeed be investigated as a possible future competitor for the IFR. But what would be gained by putting off demonstrating the IFR/PRISM technology while waiting to see if thorium really lives up to its promise? Nothing would be lost by getting a fleet of IFRs up and running. They could be breeding fissile for decades while a possible thorium fleet gets up and running, and the IFR-bred fissile — several times more than was started with — could be used for expanding the hypothetical thorium fleet at the end of the IFRs’ lifetimes.

If the current perceived urgency is to sequester plutonium to put it out of the reach of proliferators, that can be done much faster with early deployment of IFRs rather than by later deployment of thorium reactors — and each IFR will sequester 8 – 10 times as much plutonium (Pu) per GWe as a thorium reactor.

– George S. Stanford 11-29-10

D. Meneley wrote:

On the matter of thorium, George and others have repeated a . . . realistic picture.

[Boosting thorium] will do no good. This is another idealist’s dream, like large-scale wind energy. They only want to save the world and are not interested in practical details.

If you’ve tried to do control, fuel cycle, and safety system design on a thorium reactor you’ll not be so enthusiastic. The flux shape is a strong function of the past flux shape — because of the protactinium. After you shut the thing down you must account for the later reactivity increase. And then there’s the detail of not having any fissile isotope to start up in the first place.

If you’re using thoria fuel, how are you going to extract the U233 economically?

And so on.

Thorium if absolutely necessary, but absolutely no thorium if not necessary.

-Dan Meneley 11/27/10

P. Peterson wrote:

George,

Your assessment on the relative technical maturity of LFTR versus IFR is correct.

But there are other substantive technical differences besides the lower fissile start up requirement for thorium reactors.

Thorium reactors operate in with a thermal spectrum, which allows them to use graphite as the primary structural material in the reactor core. Graphite can be heated to very high temperatures without losing structural integrity. Combined with the very high boiling temperature of the fluoride-salt coolant (> 1400°C), thorium reactors can deliver heat at substantially higher temperature (between 600 and 700°C with current primary pressure boundary structural materials) than IFR (between 370 and 510°C with current fuel cladding materials). This is a sufficiently higher temperature that several options exist for gas-Brayton power conversion, while at the IFR temperatures steam Rankine is likely to remain the most practical option.

There are a number of substantive theoretical advantages to gas Brayton power conversion (this is the reason Brayton cycles are now used universally with natural gas), but essentially all of the existing turbine and compressor technologies optimized to open combustion cycles and thus substantive development is needed to adapt it to nuclear power conversion. Once successfully developed, though, one would expect substantial commercial pressure to move from steam Rankine to gas Brayton cycles as the dominant approach for nuclear power conversion (as has already happened with natural gas).

There are a number of substantive theoretical advantages to gas Brayton power conversion (this is the reason Brayton cycles are now used universally with natural gas), but essentially all of the existing turbine and compressor technologies optimized to open combustion cycles and thus substantive development is needed to adapt it to nuclear power conversion. Once successfully developed, though, one would expect substantial commercial pressure to move from steam Rankine to gas Brayton cycles as the dominant approach for nuclear power conversion (as has already happened with natural gas).

The other major differences arise from the different thermophysical properties of the two coolants. The fluoride salts have volumetric heat capacity slightly larger than water and about 4.5 time larger than sodium. So the primary systems for thorium reactors are physically much smaller than for IFRs, or alternatively, a primary system of the same physical size can produce substantially more power (factor of a 2 to 4). Thorium reactors have no sources of stored energy that can pressurize containment, so they also can use a compact, low-pressure containment structure and thus a correspondingly smaller reactor building.

These are substantive technical differences that are likely to affect the relative levelized cost of electricity (LCOE) produced by the two systems. But one of the major issues with LFTR is that one must overcome multiple, substantive technology development problems simultaneously (gas-Brayton power conversion, qualification of materials for corrosion resistance, on-line fuel processing, licensing for fluid-fuel reactors). This creates a significant activation energy problem, even if the final LFTR technology would have desirable LCOE and sustainability characteristics. One of the reasons that we’ve been working on solid-fuel variants at UC Berkeley is to see if one can reduce the activation energy barrier by capturing most of the LCOE benefits (which come primarily from improved power conversion efficiency and reduced capital cost relative to advanced light water reactors [ALWRs]) while keeping the licensing approach much closer to that used for passive ALWRs and not taking on the technical issues for fluid fuel.

In the end, LCOE will be a dominant consideration in commercial decisions to deploy nuclear power. In the near term the best opportunities involve further improvement to ALWR technology and construction methods (with AP-1000 providing the best role model to date). In the longer term some mix of uranium fast spectrum and thorium thermal spectrum reactors is likely to emerge as optimal.

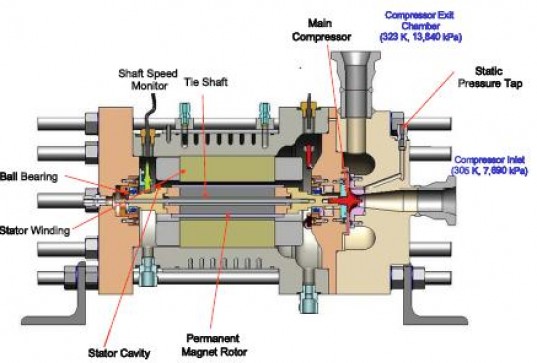

-Per F. Peterson 11/29/10

G. Stanford wrote:

Per:

Thanks much for the additional information, clarifying the technical challenges and strengthening the case that thorium power is worth pursuing and might well have an important role down the line.

While the LCOE will undoubtedly be an important consideration, it seems to me that breeding potential also is destined to be important if we are to have abundant clean energy. It also seems likely that thermal efficiency per se will not ba a major issue, in view of the very low cost of fuel for breeders (or “isobreeders” like the LFTR) — but you point out that the Brayton cycle potentially offers significant additional advantages.

I gather that you do not take issue with the proposition that it would behoove us now to complete the development of what is currently closest to commercial readiness with the characteristics needed for an assured indigenous energy supply — namely LMFBRs with metallic fuel and pyroprocessing. At present, that appears to be a U.S.-developed technology that we have abandoned, bequeathing it to other countries for exploitation.

Cheers,

– George S. Stanford 11-29-10

P. Peterson wrote:

George,

For LFTRs, the breeding potential may not be particularly important, as long as they can achieve isobreeding. Uranium from seawater provides a backstop technology that sets the maximum cost of fissile material, much as coal-to-liquids provides a backstop for the cost of oil (absent a price on carbon dioxide emissions). The startup of an isobreeding LFTR requires about 1/4 to 1/2 the fissile needed to start up an LWR, and uranium from seawater will have a cost around 4 times greater than current uranium prices. Thus the capital cost for the fissile to start up isobreeding LFTRs will be comparable to the current cost for the initial core loading for LWRs, which constitutes a modest fraction of the total capital cost of current LWRs.

Our experience to date is that “backstop” energy technologies never emerge to be economically competitive, because lower cost alternatives tend to be developed instead (at the scale that we use energy, the economic incentives are very large).

So I would be very surprised that the cost of fissile will ever rise to the point where one would actually begin commercial efforts to recover uranium from seawater (although there is always some slim probability that the government might in the future enact a “seawater uranium portfolio standard,” to create an assured market for seawater uranium, so the technology will be brought to commercial readiness regardless of cost). Absent such government intervention, the cost of fissile to start up LFTRs will likely remain lower than the cost of fissile to start up current LWRs, in perpetuity.

My expectation is that the LCOE for electricity from ALWRs will drop well below the LCOE for new pulverized coal plants before the end of this decade, as Westinghouse’s costs to build AP-1000′s and enhancements to the AP-1000 drop and as competing LWR technologies for the AP-1000 emerge, and as construction methods improve further. Financing nuclear construction will likely remain a challenge, although SMRs may prove to be helpful in this respect.

But we need an aggressive effort to develop multiple technologies that can improve upon and ultimately replace ALWRs. Fast-spectrum reactors clearly have advantages, along with thorium cycles, from the perspective of fuel cycle. IFR metal fuels are vastly better than conventional oxide fuels from the perspective of affordable and secure fuel recycle. LFTR is also a potentially attractive technology, but clearly has substantial technology risk. So yes, I strongly support demonstration of IFR technology. The key issue is that IFR needs to remain a part of a portfolio of technologies the federal government invests in, and that IFR demonstration needs to sustain discipline to assure that federal investment is likely to result in commercial success

A simple type of evidence, which Congress has required for the next-generation nuclear plant (NGNP) project, would be 50% cost sharing by commercial interests. I think that this approach is too simplistic, since it does not recognize how risk changes during design, licensing, and construction of a demonstration reactor. The best approach is to require very small or zero commercial investment at the stage of conceptual design and NRC pre-application review, moderate commercial investment during detailed engineering and NRC licensing, and substantive commercial investment for the construction of a prototype unit (where the intellectual property and up-side commercial potential ends up being owned by the commercial entities who invest).

A simple type of evidence, which Congress has required for the next-generation nuclear plant (NGNP) project, would be 50% cost sharing by commercial interests. I think that this approach is too simplistic, since it does not recognize how risk changes during design, licensing, and construction of a demonstration reactor. The best approach is to require very small or zero commercial investment at the stage of conceptual design and NRC pre-application review, moderate commercial investment during detailed engineering and NRC licensing, and substantive commercial investment for the construction of a prototype unit (where the intellectual property and up-side commercial potential ends up being owned by the commercial entities who invest).

This sort of decision framework is also easier to implement in statute, since one can authorize the needed expenditures, but the actual appropriations can depend upon progress being made and commercial investment materializing.

What commercial interests will tell you is that it is much easier to make a decision to make a substantial investment if they have an NRC construction license to build a reactor, while it is almost impossible if the reactor is just a concept that needs a lot of detailed engineering work. But in the end, the commercial entities that perform this reactor development work are also in the best position to assess its commercial potential-so a lack of willingness to place some commercial money at risk (less earlier and more later) should be viewed as evidence that the concept needs more R&D, not accelerated demonstration.

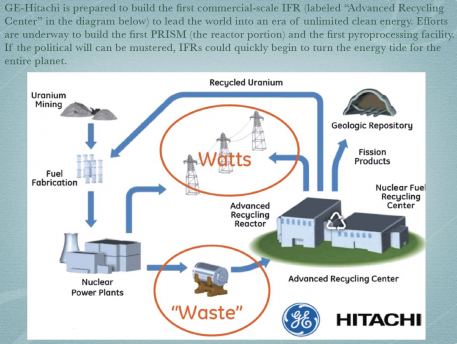

For IFR, though, the availability of affordable fuel is a big issue. It requires the capacity to recycle used LWR and IFR fuel, as well as to test and qualify recycled fuels for use in IFRs. This is a problem that the commercial sector is not going to be willing to take on, and thus it requires purely federal effort.

-Per F. Peterson 11/29/10

George Stanford wrote:

Per,

Thanks for the further elucidation.

To get quantitative about LFTRs, suppose the world were to want 50,000 GWe of isobreeding LFTRs by 2100, primed with 10% EU at 1 tonne of U-235 per GWe. That U-235 would be contained in 10 tonnes of EU, which would come from ~200 tonnes of Unat. Thus the amount of uranium to be mined would be ~ 50,000 x 200 = 10 million tonnes of Unat — which is well within the realm of the possible.

However, a downside would be the perpetuation and global expansion of uranium enrichment infrastructure, with its proliferation implications. Also, left over would be some 9.5 million tonnes of orphaned depleted uranium containing 9.5 million GWe-years of unavailable (and unwanted) energy.

– George S. Stanford 11/30/10

D. Meneley wrote:

George, Per:

You guys seem to be intent to ignore the only fully developed, in service, economically competitive, high conversion ratio, and safe medium size reactor system on earth [namely, the CANDU-type heavy-water reactor]. Perhaps you could explain why.

Dan Meneley 11/30/10

G. Stanford wrote:

Dan:

Sorry if I slighted the CANDU. It’s a fine reactor design, struggling to acquire a bigger share of the international market. To believers (like you and me) in the importance of conserving fissile material, its high conversion ratio is an important asset. But – apart from the fact that it doesn’t need enriched uranium — to a first approximation it’s just another thermal reactor. Since most of the generalities about LWRs apply also to CANDUs, much of the time it’s convenient to use the term “LWR” as shorthand for “uranium-based thermal reactor.”

While I can’t speak for Per, of course, I suspect that he would ascribe less importance to a high conversion ratio than I do.

George S. Stanford 12/01/10

.png)

Is anyone here attending the thorium symposium next week?

http://www.thoriumaustralia.com.au/symposium.html

Where did they advertise this and why does it have to be in Canberra? That looks like an excellent symposium, provided that they’re talking about LFTR and not LightPower etc.

The emphasis seems to be on MSRs. It appears to be largely backed by the Cheks, given the preponderence of Chek presenters. I became awate of it through the media. The registrations have closed now, but I was wondering if anyone else had arranged to attend.

It would be great if they were recording the presentations. It would be quite interesting to hear the Hon. Martin Ferguson’s views on thorium and nuclear power in a broader context, especially given the upcoming ALP National Conference.

Without pre-empting the discussions at the thorium conference it’s not clear that the claim it can produce baseload power means before or after the development of the MSR. Australian companies Lynas and Arafura will become a major thorium producers from about 2013 with a larger tonnage than uranium.

http://www.smh.com.au/business/the-rise-to-power-its-elemental-20111106-1n1vc.html

Here’s something I wrote about a year ago:

Here are some of the advantages/disadvantages relative to IFR (Integral Fast Reactor).

LFTR is better than IFR because:

* better coolant:

* chemically stable liquid salt instead of liquid sodium which reacts violently with air or water

* higher heat capacity

* 1/5th the fissile load per megawatt

* Liquid fuel

* fuel integrity cannot be damaged by radiation and not subject to fatigue or pressure failure

* fuel allows continuous removal of Xenon so no startup transient poison

* suitable for continuous online reprocessing for fission product removal

* safer

* minimal geometric configuration, so cannot become super critical through an accidental reconfiguration

* already fully moderated, so cannot become super critical through accidental moderation (like core becoming physically close to materials containing hydrogen such

as concrete or water during an overheat meltdown accident)

* can be designed with no excess reactivity and continuous online refueling

* thermal spectrum operation makes it much easier to control as all operation is below nuclear resonances

* burning Th232 produces ~1% of the long-lived higher actinide waste compared to burning U238 (the fertile fuel starts with 6 fewer heavy nucleotides)

* lower breeding ratio so easier to control the proliferation of reactor operators by controlling access to startup fissile material

IFR is better than LFTR because:

* has been much more thoroughly studied and funded

* burns U238 which is very widely stockpiled

* burns spent PWR fuel which would be nice to get rid of

* high theoretical breeding ratio (1.8 vs 1.3) so more reactors can be started up more quickly — this was true, but now the world has so much stockpiled bomb plutonium that this may no longer be a practical limitation

* U238 is more available from seawater than Th232

Ultimately I think a mix of a few fast-spectrum reactors (IFR or chloride salt fast MSRs?) and a much larger number of thermal spectrum thorium burners with breeding ratios just under 1.0 are probably the safest and easiest to control. But I think that starting with the harder fast spectrum design is more expensive and less safe. But of course, I’d rather build IFRs than just sit around while we wreck the atmosphere.

Some would argue that we can only afford the resources to develop one technology branch. I disagree. The amount of money required to develop a technology is quite small compared with the cost of 20-50 years of the world’s energy consumption. The real problem is an under-investment in technology development combined with the stifling effect of draconian regulation. The main advantage (from my perspective) of different nations pursuing independent nuclear technology development programs is that some of those countries are relatively free from excess regulation. Others might argue that this lack of regulation will result in radiation spills or nuclear weapons being used and that is even more unacceptable than systemic climate change. In my opinion, those dangers are overstated and those priorities are inverted. Let’s build all of these:

1. more Gen III LWR like AP-1000

2. Advanced high temperature, salt cooled reactors like Per’s AHTR

3. thermal spectrum, liquid fluoride fuel Th-232/U-233 reactors like Kirk’s LFTR

4. fast spectrum, liquid chloride fuel U-238/Pu-239 reactors

5. and even fast spectrum, liquid metal cooled, solid metal fuel U-238/Pu-239 reactors with integrated reprocessing like IFR.

Then we can stop worrying about energy costs and damaging the environment. We can do all this for far less than 1% of the cost of the energy we will consume over the next 20 years.

MODERATOR

Chris – please be aware that BNC requires substantiation of personal opinion by the use of refs/links etc. Please supply these.

Chris Uhlik, what does “safer” mean? Is there really a need for more technical safety beyond a certain standard?

Cultural or operational safety is just as significant, IMHO. A workforce which manages complexity or the unexpected safely, which adapts to change safely and does the mundane safely is capable of achieving far higher standards of safety than simply relying on engineered safety systems.

I am not saying this to discredit the principle of continuously improving safety programs, only to suggest that the law of diminishing returns suggests that once the engineering design is appropriately safe, the biggest issues relating to safety will not be improved by further design.

On re-reading what I have just written, I realise that it is a bit clumsy, so I’ll try another tack.

If a technology is safe, and by this I mean really safe, as in fit for purpose, it matters not to me what it is called – IFR or LFTR or whatever – it is adequately safe. More layers of redundant designed-in safety systems suggest to me overdesign and unjustified waste, the cost of which would probably be spent much better elsewhere in the community, perhaps on mental health initiatives or eliminating malaria or something else which has statistically significant personal cost. I’m loathe to put a price on human life, but expenditure must be justified by anticipated returns or we will all end up joining the Helen Caldicott Party.

John Bennetts — Well stated as I have come to expect from you. Current Gen II NPPs are about as safe as eating peanut butter, so additional safety is less an issue that simplicity of desing which ordinarily lowers cost. For example the NuScale Gen III unit, soon forthcoming, requires less concrete and less steel per kilowatt; lower capital cost per kilowatt. But because of its convective cooling desing (which I find quite elegant) it is also about 10-100 times safer than eating peanut butter; fine, a useful sales point.

+John Bennetts, I meant “safer” in the sense that traveling on the ground is safer than flying. It might not be true for a particular situation (e.g. flying a Quantas 747 may be safer than walking through a jungle) but in general flying involves high kinetic energy and weather which can cause dramatic problems. A low pressure, inert coolant has fewer ways to go wrong and will likely go wrong in a less dramatic fashion than a high pressure steam system or a liquid sodium metal system. That said, any of those systems can be engineered to any properly specified level of safety at some cost. Just as the modern jet transport is highly refined and quite safe. But it takes many years of experience to get there, and more years are required for systems that are intrinsically more prone to energetic phenomena.

> BNC requires substantiation of personal opinion by the use of refs/links etc. Please supply these.

I said many things that I think are self evident. Please ask a more specific question and I’ll back up that statement.

Perhaps some confusion is due to the posting being stripped of leading whitespace. This makes my outline look more like a list.

I regret that I did not answer George Stanford’s message of 12/01/2010, earlier. NO, the CANDU is not “just another thermal reactor”. The difference lies in its high internal conversion ratio, and its ability to operate primarily on a mainly-thorium cycle. China and India both see this difference very clearly.

It is obvious that the world must build many, many thermal reactors very soon, to overcome the serious consequences of our over-dependence on coal and oil. Then, we will need to pay attention to the shortage of available fissile materials. This leads us directly to the need to build thermal reactors with high internal conversion ratio, in order to reduce the demand on enrichment services as the world nuclear fleet grows into thousands of units. (See “Transition to Large Scale Nuclear Energy Supply”, at , under Members Views).

There is only one fully developed nuclear energy system now in existence that can satisfy this need for a thermal reactor that can prepare us for the coming transition to a sustainable long term energy system based on uranium and thorium. It is the CANDU system.

Sorry, my previous message was altered by removal of the reference which is necessary to the argument. That reference is to the website of the International Nuclear Energy Academy.

Just google it.

https://inlportal.inl.gov/portal/server.pt/community/inea/696/meeting_reports_and_news

I’m planning to go to the Canberra symposium next week. Looks like the initiative came from one of the miners, but there are some pretty heavy actors on the program, including the minister, the deputy head of the department, and the head of ANSTO. It will be interesting to hear what the Czechs are up to.

@ P. Peterson 11/29/10:

This paragraph caught my eye

Could you provide any links about the cost projections.

@ John Bennetts, on 17 November 2011 at 3:24 PM

Here, here to that comment.

I see how sodium coolant is always listed as a disadvantage of the IFR system. I can see that point. If not threatening to the reactor itself, sodium fires have been a nuisance at fast reactor prototypes all around the world, leading to shutdowns and increased cost of operation.

Why not switch to lead? Lead has already been used in fast reactors in the Soviet Union and it doesn’t react violently with water or air.

Barry, George, Dan, Per,

I have little understanding of the alternative Gen IV’s and it is not my focus. However, I would like to see a simple table with the most likely Gen IV contenders compared on the most important parameters. Some important parameters that come to mind are:

1. A realistic estimate of LCOE (by a defined date).

2. Most likely date by which their LCOE could be competitive with Gen III+, recognising that the LCOE of Gen III will decrease over time

3. Construction duration

4. Plant life

5. Suitability for use in under-developed and early-stage developing countries

Any other parameters that are relevant regarding commercialisation and cost. I intentionally did not include “safety” as a key parameter. As far as I am concerned, any Gen IV that gets through licensing will be safe enough, although I accept it will have accidents just like any other industry. So the safety is actually included in the LCOE.

Can either IFR or LFTR do all we need alone or will we need both?

@Max: I can just imagine the outcry from the anti-nuke campaigners the first time there’s a molten lead leak… (never mind the phenomenal amounts of lead emissions from the various smelters around the world!)

I thought I remembered that there are chemical problems with using molten lead as a coolant (affecting steel alloy strength), but Wikipedia tells me it’s been done since the early 70s, and commercial designs are on the drawing board. I must have been thinking of some other coolant…

One of the questions about IFR technology is their likely breeding ratios. Oral claims of 1.65 breeding ratios have been made, but this how much R&D is required to get there is unknown, and there are grounds for doubting the safety of a high breeding ration IFR.

A better approach might be a lower breeding ratio IFR which offers both Uranium and thorium fuel cycles.

Considering thorium’s breeding process as — Th 232 +n -> Th 233 -> Pa 233 -> U 233

The long half life of Pa 233 (27 days ) must put a significant constraint on the design options for a thorium reactor. In order not to lose too much Pa 233 to neutron absorption as U 234, the probability of neutron absorption by Pa 233 has to be less than the probability of its beta decay to U 233. That could be arranged, either by having a low neutron flux across a large core, or by having a long resting time for fuel removed from the core.

At first glance, it would seem that thorium reactors have to be big to be self-sustaining. However, neutron economy could be augmented by the addition of recycled plutonium , which would be one way to burn the stuff without breeding more plutonium. It might also allow the design of small “thorium” reactors.

An IFR could be lead-cooled as well. Lead coolant would be more acceptable to the public, since the fire hazard of sodium is often the No.1 argument brought forward against the deployment of fast reactors.

Or is there something about lead coolant which makes it less desirable? Is it more difficult to achieve high breeding ratios with lead or why are there so many sodium-cooled designs?

It can’t be material issues, since lead-cooled systems have already been successfully demonstrated as mobile power reactors on Soviet submarines.

I found something:

http://www.ne.doe.gov/pdfFiles/SodiumCoolant_NRCpresentation.pdf

Sodium vs LBE vs lead vs helium

Outlines why sodium is the preferred coolant.

I definitely don’t want to see helium-cooled fast reactors. Sounds like a recipe for disaster. Apparently they aren’t even sure whether natural helium circulation would be able to remove the decay heat of a fast reactor in shutdown when all power to the pumps is lost. They would have no safety advantage over present-day light water reactors.

With the best will in the world, chaps, this is a misplaced, and essentially academic argument. We have very much more urgent needs.

The argument is one of priorities, and of what is needed for the sector at this moment.

Right now is probably (Fukushima aside) probably as favourable a moment as nuclear has or will see for years. Interest rates are low, the decarbonisation agenda is prominent, uranium supplies are plentiful, and we have on the stocks a number of designs that have the potential to be built quickly and consistently. I’m not willing to bet things will look half as favourable in a decade or two.

Counter to that we have to acknowledge that (from an investors perspective) that outside of France and Asia, the nuclear industry’s track record on delivery stinks. Plants arrive years late and heavily over budget, and even when eventually delivered take years to get to a point where they perform to design specs (look at US capacity factors from the 1980s and the present day).

A big contributor to that, in the US and most of the world, has been the complete failure to settle on standardised designs, and then “productionise” them – think six different BWR generations with God knows how many variations within each, for example. Think of the plethora of demonstrators and prototypes.

That is NOT the hallmark of a mature industry.

And we should be a mature industry. It’s 55 years since Calder Hall and its Russian equivalent started supplying power to the grid, 53 years since Shippingport started up. In the same timescale aviation went from the Wright Flyer to the Boeing 707.

To use that analogy to the aviation industry, it’s as if after building the first dozen 707s, Boeing radically revised the design producing something else with no common parts, different flight controls etc. Oh, and to make it worse, that redesign necessitates a whole new regulatory licensing process.

That – in the eyes of the people who take the decisions to buy and fund new plants – is roughly where we are. Worse, unlike the aviation industry, we’ve no track record of eventually getting the situation stabilised then being able to give reliable dates, prices, performance and cost figures and so on. Instead, we’ve got the Olilkuoto/Flammanville debacle setting us back even further.

That’s why the US industry has needed a loan guarantee programme. Loan guarantees don’t change the long term economics of plant, but what they do is protect lenders and investors against the risk of companies buying the plant going into default because they’ve gone bust – as a result of delays and over-runs. It lowers borrowing costs by removing the risk premiums. But that’s largely failed, because the calculation of the “insurance premium” based on past experience has been horrible (the fact that the same logic hasn’t been applied to renewables isn’t relevant).

So, what at this stage would be a smart response? Is it to launch on yet another round of demonstrators, prototypes and radical new technologies, which will inevitably in their turn hit delays and over-runs (think B787 and Airbus 380) and worsen an already bad reputational problem?

And especially is it smart for the enthusiasts for some of the new technologies to argue that the current choices are fundamentally misconceived, to imply that they’re inherently unsafe or to argue on the basis of fuel economy – when there’s no realistic prospect of uranium shortages for a half-century or more?

After all, no-one realistically regards any of the GIII+ designs as anything other than extremely safe; and they can all happily run conventionally recovered MOX should those putuative uranium shortages manifest themselves.

Or is the smart choice to knuckle down and focus the limited available resources and capital on showing that the current designs can be delivered reliably? Even better, to concentrate on the learning curve, economies of scale and incremental improvements to those designs, and deliver them cheaper, faster and with better performance?

To put it another way – to establish investor confidence we need a dozen AP1000s consistently delivered on plan, and getting down to 36 months construction time a lot more than we need an IFR prototype that might be commerically competitive in 30 years, if uranium prices skyrocket. We need eight or ten EPRs up and running, and maybe testing burnable poison fuel (so they can run for four years without refuelling) more than we need yet another an HTGR demonstrator.

Let’s return to the Boeing analogy. Imagine they’ve built the first dozen 707s – they’ve been late, expensive and it’s taken several years in service to get each one to be reasonably performant. However, most of the bugs have been worked through , and we’ve got a manufacturable and operable version just about ready to go. Boeing wouldn’t now turn around to Government, customers and investors and say, “we’ve thought of something much better – a blended wing design. So we’re going to focus our R&D effort on that on that. Oh, you can forget all the investment on the 707, that’s old hat”. I’d expect the CEO – rightly – to last about 5 minutes….

The sane thing to do instead to do what the GIV consortium is actually doing. Focus on lab scale R&D and paper studies with the possible deployment of pilot plants in the 2030s, at which point there MAY be some indications of the fuel issues that would make thorium or fast reactors attractive.

In the meantime, concentrate on getting the GIII+ designs really working, and then (only then) exploit them more. Get build times down to a consistent 36 months. Demonstrate availabilities of 95%+ within two years of start up, and show economically attractive load-following. Then we might see nuclear utilities with the same cost of capital as non-nuclear ones – that alone would make nuclear hugely more competitive. At that point, think about a stretch the AP1000 to 1400MW and the EPR to 1800 or 2000MW for the same unit prices as they cost at the moment, or less, or extending refuelling intervals.

Once that’s been done, and only then should the industry will be in a place to look for funding for radical alternatives

MODERATOR

This comment is off topic on the discussion of IFR vs LTFR. A general opinion on the state of the industry,financial aspects etc should be on an appropriate/or Open Thread. Further violations may be deleted.

I believe Andy Dawson is right when he says the industry needs to concentrate on delivering a reproducible design. That said, I believe the problem (delays and cost overruns) is rarely due to design issues, but rather regulatory issues. Not licensing issues, but delays due to inspections, changing requirements (regulatory ratcheting), protest movements, non-cooperative state governors, political maneuvering, etc. The aircraft industry has enjoyed the ability to make continued progress while routinely killing hundreds of people while the nuclear industry sneezes a puff of tritium laced steam and the whole world freaks out. To stretch the analogy, suppose a 707 knocked out a runway edge light during a crosswind landing; the fleet gets grounded while the regulatory agency demands that the airplane be redesigned to eliminate the possibility of landing more than 1/2 centimeter from the runway center line. Then, perhaps worse, the industry responds with an improved (but more expensive and time-consuming) new design that actually results in more accurate landings, but at twice the cost and all planes under construction are torn down and rebuilt to incorporate the new features.

This is the aircraft industry’s equivalent to Three Mile Island

http://www.nytimes.com/2010/11/05/world/asia/05qantas.html

A significant system failure where nobody died and the passengers cheering the pilots. The A380 still flies every day yet undamaged reactors in Japan remain shut down and almost nobody is cheering the Japanese for their magnificent and largely successful effort to safe their reactors following the largest tidal wave in 100 years — perhaps roughly equivalent to landing a plane with half a wing blown off without killing any passengers, but severely damaging some airport buildings and leaving the plane a wreck.

“Currently, 43 of Japan’s 54 nuclear reactors are shut down, either because of mechanical problems or routine inspections, which must be conducted every 13 months. Local approval is required to restart nuclear power plants, even after routine inspections, and local leaders fearing repercussions at the polls have been loath to provide it.” — http://www.huffingtonpost.com/2011/11/12/japan-fukushima-reactor-e_n_1089900.html These are not new designs. These are existing plants that were operating safely, but are not being allowed to be restarted out of fear. The nuclear industry is hobbled by fear, not by bad design decisions.

MODERATOR

See my comment to Andy.

(Deleted as off topic please repost in the Open Thread)

(The commenter to which you refer has been advised to move to the Open Thread.)

(Deleted as off topic – please re-post in the Open Thread.)

(The comment to which you refer has been deleted as off topic on this thread.)

(Off topic – re-post in the Open Thread.)

At best the LFTR seems many years away. However within just a few years Australia will be producing more thorium than uranium from monazite sands and rare earth by-production. This suggests using CANDUs as a ready-to-go application for thorium. What I don’t know is how much more energy can be extracted from thorium using LFTRs as opposed to CANDUs and reprocessing if that is applicable. My questions are

1) are LFTRs worth the wait?

2) what do we do with all that thorium?

Here in one the west coast of the USA, our utility PG&E gets 10.5% guaranteed rate of return(*) on their capital investments. That sounds pretty sweet doesn’t it? How much would you like to spend on your next powerplant if you were guaranteed 10.5% ROI for 30 years? Answer: as much as I can get away with. So who cares how much it costs to ensure the safety of the people living near the powerplant. The utilities have a strong incentive to add every conceivable safety feature at any allowable cost. Think of the children!

(*) They asked for 13.1% and were allowed _only_ 10.5%

http://www.portlandgeneral.com/our_company/corporate_info/regulatory_documents/filings/docketed_filings/UE-88/docs/UE-88-Remand_Exhibit_6600_Blaydon.pdf

(The comment to which you refer has been deleted as off topic and asked for a re-post on the Open Thread.)

Max — The Russians have a ‘working’ lead or lead-bismuth cooled design. The Hyperion will be similar, just much smaller.

I suppose these are therefore Gen 4 although I fail to understand just why.

LFTR is a good design for the long run, but it is the wrong design for build out in the next 50 years. The first generation MSR should be the simplest possible uranium fueled reactor. It has several advantages.

1… No continuous online reprocessing. Just replace graphite and clean the salt at 30 year intervals.

2… Uses 1/4 the uranium of conventional reactor. Fuel cost is negligible for the foreseeable future. Next generation reactors do not need to be breeders.

3… Shortest development time and cost in a well funded engineering environment unconstrained by political and emotional constraints. It would be a scaled up version of the technology demonstrated at Oak Ridge in the 60’s, using similar materials running a steam cycle at relatively low temperature.

4… Easiest and lowest cost to mass produce due to compact size and lack of complex safety systems.

5… Highest level of safety without complex active safety systems. Volatile fission products are extracted as they are produced and converted to safe chemical forms that can easily be stored and passively cooled without risk of meltdown or criticality.

With molten salt there is no large bolus of volatile fission products trapped in fuel pellets waiting to be released in an accident with fuel melting; for example, cesium atoms quickly react with fluorine ions to form cesium fluoride, boiling temp 1251 C vs. 671 C for elemental cesium.

Machines designed for high temperature operation are easier to passively cool than machines containing low melting temperature materials like solid metal fuel.

Liquid fuel can be redistributed into a geometry that is critically safe and easy to passively cool while solid fuel reactors must be protected in their existing geometry.

http://www.thoriumenergyalliance.com/downloads/TEAC3%20presentations/TEAC3_LeBlanc_David.pdf

This technology can produce abundant supplies of reliable dispatchable energy at a much lower cost than burning fossil fuel in the shortest time. KWh’s from simple MSR reactors will be available sooner and at lower cost than kWh’s from LFTR or LMFBR.

(The commenter you refer to has been judged off-topic and asked to move to the OT.)

(Deleted off topic on this thread.)

Bill Hannahan, on 18 November 2011 at 9:19 AM said:

How can you have “well funded” and “unconstrained by political and emotional constraints”.

Wasn’t that supposed to be the case for EBR-II, and what happened to it?

(The comments to which you refer have been deleted as off topic.)

(Deleted off topic)

It doesn’t matter much which nuclear fuel we burn for the next several hundred years. What matters is how hot it burns. Simple, set and forget hot heat will enable nuclear to have sufficient mass-market penetration to make a meaningful dent in Global Warming – the goal of the BraveNewClimate web site.

All conventional LWR reactors run about 550F. The IFR comes in at about 900F. But it, in turn, is outclassed by the 1,300F LFTR.

Hotter is better when it comes to heat. The 910F BN-800 IFR is an excellent example of what happens to an amply large reactor – with the most excellent of development pedigree – that still is neither fish nor fowl in the temperature world.

There are excellent reasons steam temperatures are what they are. Once over 1,100F, you are in a position to make world-standard 1,005F superheated steam, once over 1,200F, supercritical and ultra-critical steam. At 1,300F, you are in Stirling air turbine territory. These applications, in the 1,200 largest of the world’s 30,000+ fossil fuel power plants are where more than 30% of ALL Global Warming is coming from now.

Today’s nuclear reactors have become huge temples of technology moving at all deliberate glacial speed. The IFR is likely to be a continuation of that paradigm. Not a good omen for quickly reining in Global Warming.

A pot, a pump, and pipe was someone’s quip about the omnivorous basic converter type of thorium-fueled molten salt reactor they experimented with at Oak Ridge Laboratories.

I think after what we’ve been through, much simpler, much hotter, and much quicker is what the World needs. Let’s take the LFTR back off the shelf.

(The comment to which you refer has been deleted as off topic on this thread.)

Jim: Hotter is better? No, that is wrong. Cheaper is better, any day. Pressing materials into service at their extreme limit of tolerance is not only unsafe, but it usually is a poor economic alternative. Cheap fuel — natural uranium — at a reasonable temperature is a much more attractive choice.

Andy Dawson @ 3:46: You certainly make many good points, but allow me to comment on a couple. You write: “After all, no-one realistically regards any of the GIII+ designs as anything other than extremely safe; and they can all happily run conventionally recovered MOX should those putuative uranium shortages manifest themselves.” MOX is a non-answer. It increases uranium utilization from 0.6% to 0.8% (whoopee!), costs huge amounts to build and operate the plants translating into fuel vastly more expensive than fuel made from virgin uranium, and can be recycled once, leaving you with virtually the same spent fuel problems we face now (which, admittedly, aren’t that big a problem except in the eyes of the uninformed public and policymakers).

You also write: “… to establish investor confidence we need a dozen AP1000s consistently delivered on plan, and getting down to 36 months construction time a lot more than we need an IFR prototype that might be commerically competitive in 30 years…” The very first two ABWRs were built in Japan in 36 and 39 months and worked fine. This won’t be a problem. Your contention that IFRs “mmight be commercially competitive in 30 years” is a baseless assertion. And good luck getting ten EPRs up and running. The AP-1000 and ESBWR are going to eat AREVA’s lunch.

Your “sane thing to do” reasoning that IFRs and other should be put off until we finally build pilot plants in the 2030s completely misses the point on many of the IFRs strengths: It will be small, mass-producible, easy and cheap to fuel (with the fuel itself being better than free aside from the easy and inexpensive fuel fabrication) and will operate as a non-pressurized system. Once the first pilot plant is completed they could be rolled out very quickly. The only limitation would be on fissile startup inventories.

The IFR is hardly a “radical alternative” except in the sense that it can revolutionize power production around the globe. It’s not like fast reactors haven’t been built and operated for decades. While I agree that Gen III+ reactors should be built, turning one’s back on the IFR just because you’re building III+ is like saying you can’t walk and chew gum at the same time.

Just a word about “hotter is better” and Per’s comments about Brayton vs Rankine cycles: The most recent developmental work with supercritical CO2 heat exchanger systems will very likely result in allowing the PRISM (or other systems) to increase its power output by about 50% and switch to the Brayton cycle. This has been worked on at Sandia and is pretty close to the point where these much smaller and efficient systems will be deployable—almost surely by the time the first PRISM is built. So you’ll be able to have a very efficient 550C system (and, by the way, eliminate the sodium heat-transfer loop, which I suppose will make some people more comfortable).

To reinforce Tom Blees point, I have no issue with seeing a dozen AP1000s delivered on plan — indeed, that is happening in China now. If “we” is the US, and they cost $6 billion per AP1000, then that’s $72 billion for the AP1000s plus another say $10 billion to invest in getting BOTH the IFR and LFTR to commercial ready status (1/7 the cost of the 12 AP1000s). Putting that entire expense in the context of the estimated $26,000 billion required globally in energy investments by 2030, and we’re talking peanuts. That’s the point. Let’s do both, and stop pretending that crises can be solved by taking on only one issue at a time.

Oh, and following the moderator’s advice, let’s move further discussion of where nuclear investments ought to be directed to the Open Thread. This is a post about the IFR and LFTR comparisons. Not Gen IV vs Gen III.

Moderation is not available 24/7 so please be aware of which thread you are commenting on and avoid being led by a commenter who posts off topic. It is important to keep on topic to avoid rambling discourse which deflects from the current discussion. Unfortunately BNC does not have the facility to re-post comments on other threads so deleted off topic comments must be re-posted by the individual.

The 1982 Nuclear Waste Policy Act http://en.wikipedia.org/wiki/Nuclear_Waste_Policy_Act is a problem for IFR and LFTR development. The Act prohibits the reprocessing of spent nuclear fuel (SNF) and the transport of SNF off site. This severely limits what private parties can do to further the technology of either system. Basically, no progress without being a government contractor and complying with stifling rules. This makes the technology development orders of magnitude more expensive than almost any other area. Smart, energetic engineers and scientists in the USA and many other countries look elsewhere for fulfillment.

In this regard, some of the technologies of LFTR (salts and coolants and chemical processes) look like they might be less prone to restrictive control than for example casting plutonium alloys.

+Tom Blees writes:

> The most recent developmental work with supercritical CO2 heat exchanger systems will very likely result in allowing the PRISM (or other systems) to increase its power output by about 50% and switch to the Brayton cycle.

Here’s a good source for supercritical CO2 as a turbine working fluid.

http://www.inl.gov/technicalpublications/Documents/2906955.pdf

CO2 has a critical point at 31.5 degrees C (88.7 degF).

There are two main advantages in using supercritical CO2 as a working fluid:

1. the fluid is relatively dense compared to steam, helium, nitrogen or air at feasible pressures. This minimizes the volume of the machine and allows high power density. A supercritical CO2 turbine will be tiny compared to an equivalent power condensing steam turbine in which the output is nearly a vacuum at ~70C.

2. when compressing the expanded CO2 back to high density, ***if the heat is taken out below the critical point***, very large density increases are available without corresponding increases in pressure. This greatly reduces compressor work compared to more ideal gases. Steam also enjoys this advantage, because the pressure increase (pumping) is done after condensation so the volume change is small. Helium, air, and other more-ideal gases without phase transitions are at a relative disadvantage here.

However, this compression advantage of supercritical CO2 only accrues if the compressor is multi-stage with intercoolers at every stage. These intercoolers need to deliver relatively cold CO2 to the next compressor stage. “Cold” means “below the 31.5C critical point” with 28C being typical of simulations; see the referenced paper. 28C is not easy to achieve on a warm day. Consider that many very high power industrial heat exchangers use a nominal temperature drop of 20-50C. The size of the heat exchanger increases rapidly as one tries to reduce this temperature gap. The super critical CO2 reject-heat heat-exchangers contain high pressure (~1500 psi) and will be very large and expensive. Perhaps the only way to get 28C compressor inlets in most parts of the world will be to use cold sea water on the cold side of the HX. If the sea water is ~8 degrees C, you might manage a reasonable 20 degree C HX drop. Note that the heat exchangers in one of the ORNL thorium MSR designs (ORNL-4528) are the largest parts of the reactor system and they allowed 190F (88C) and 125F (52C) drops. http://www.energyfromthorium.com/pdf/ORNL-4528.pdf (pages 40 and 55)

In my opinion, the excitement about super critical CO2 turbines is missplaced. The physics of real world heat exchangers and the availability of low temperature heat sinks limit the utility of a working fluid with a 31.5C critical point. I’m saying it’s not gonna happen.

Bringing the subject back to IFR vs LFTR, the higher temperatures allowed by liquid salt coolants allow high thermodynamic efficiency to be achieved using off-the-shelf (600C) ultra-super-critical steam equipment.

Chris

High temperatures at the heat exchanger makes for more efficient heating of the working fluid. That increased efficiency allows a shift from the use of steam to the use of air to drive turbines. When they talked about a Brayton cycle in the post, all that was implied was a hot gas turbine. Tom commented that a higher temperature of the PRISM implied “much smaller and efficient systems”, that is, as a hot gas turbine. The simplest would be an open cycle hot air turbine. Ambient air is filtered, compressed, passed through the heat exchanger, through the turbine and dumped directly into the atmosphere.

There are distinct advantages for the expansion of energy delivery systems away from the main grid. For one thing, there is no condenser, cooling system, cooling tower or public eyesore to attract public resentment. Indeed, the nuke and its turbine are likely to be truckable. It is also significant that the power plant doesn’t need to be sited near water. That means that the town or industry it serves does not have to be on a watercourse, so industry can expand away from the existing conurbations along the coast and rivers. Deployed away from the main grid, the small air-turbined nuke would save on the need for transmission lines to connect these consumers to the main grid.

Further, being so transportable, the power plant can be rapidly deployed. As climate change advances, we must expect that the industrial and urban environments will change, possibly rapidly. We need an energy system that can be put in place as fast as we can move our homes. Similarly, we could dismantle such a unit rapidly. Depending on the design, many and perhaps all of its components might be moved from one site to the next with good fuel still in the core. (Would even an MSR be so mobile?)

Fans of giant nukes can point to their superior fuel efficiency, and in the current marketplace, their superior capital cost per power unit. However they are giant things to plan for, requiring gigantic funds to be found, suffer giant costs when delays or disruptions falter construction, and make century-long assumptions about a fixed climate, fixed public values and a fixed consumer base.

Mass production can make small, deployable nukes cheap enough to compete. Hot air turbines can make them rapidly deployable, anywhere. Climate change will require such adaptability.

Dr. Peterson has pointed out some thermophysical advantages of molten fluoride salt coolants: high volumetric heat capacity (5x sodium), high boiling point (>1400 Celcius), electromagnetic transparency (easy online inspection), low reactivity with air and water (some reactivity with water but nothing like sodium’s explosive behaviour).

I don’t think it is testiment of great in depth knowledge from Stanford, to state

Any serious research will reveal, that thorium metal has a higher melting point and superiour mechanical strength moduli, and a higher non-phase transition temperature than uranium metal. It is very much a superiour fuel compared to uranium. It does not make plutonium that can be difficult to reprocess without losses, it makes uranium (U233) as fissile fuel that is much easier to do with fully automated reprocessing. Fast spectrum means U234 absorption product and Pa233 intermediate fast fission very well. There are many other advantages but I don’t have time for that right now, I just want to point out that there are many advantages to thorium fuel. People who are involved in one research area can have little knowledge or patience for other research areas.

I would like to make a suggestion for a combined research effort between LFTR and IFR and suggest a fluoride cooled IFR with thorium metal fuel. Possibly started with plutonium from spent nuclear fuel.

@Max,

Interesting presentation, thanks. Do you (or anyone else) have a descriptions of the colors in the figure on page 21?

Any serious research also will note the awkwardly high melting point of molten fluoride salts. Reactors are not always operating — and you’ll have to have a very good heat source to keep your coolant in molten state.

@ Dan Meneley

Could you please explain the apparent contradictions in your various e-mails?

You forcefully disparage the use of thorium reactor technology in your first e-mail, ending by stating: “Thorium if absolutely necessary, but absolutely no thorium if not necessary”.

Later, you move on to champion the CANDU reactor and take issue with its having been lumped in with thermal LWRs. You state that the CANDU’s great advantage is that can operate with mainly thorium fuel.

@ Cyril R

“I would like to make a suggestion for a combined research effort between LFTR and IFR and suggest a fluoride cooled IFR with thorium metal fuel. Possibly started with plutonium from spent nuclear fuel.”

Could you elaborate? You are, I think, implying a fast spectrum. What fluoride salt combination would you recommend? What vessel lining material would you use? What delays would be incurred in qualifying materials? I like the principle, but not the possible lost time.

Great discussion. The NRC coolant comparison linked upthread is informative and shows that, for a number of reasons, sodium makes an excellent coolant.

It seems to me that the perceived safety threat of sodium’s reactivity is sometimes played up a little too much. It does react with water, which is why there is a separate sodium loop for generating steam. Sodium leaks to the air are apparently not a huge problem, and leak occurrence itself isn’t a big concern since the reactor doesn’t operate at high pressure. So these issues are not insurmountable, and seem to be about on par with sodium’s opaqueness as an engineering problem.

Lead is *really* heavy, the activation products have a long half-life, it’s difficult to keep it in a molten state, and there’s much less experience with it as a reactor coolant.

One thing that’s not clear to me about the LFTR: what kind of neutron source is used to get the reactor going?

Douglas: India and China are both rich in thorium resources, but very poor in uranium. These countries also are very poor in petroleum resources. For these reasons, thorium is a necessary part of their search for energy independence. I expect they will make use of it even though it does complicate operations.

A very well thermalized spectrum such as that existing in the CANDU design is the best for thorium utilization because of the resulting high internal conversion ratio.

I have never “disparaged” the use of thorium, but I do insist on presenting both the positive and negative aspects of its utilization.

Dan Menely: the molten salt reactor experiment worked fine, they used heat tracing on small piping and put the entire reactor in an oven. No lack of heat source after operating a few weeks – lots of fission products that make heat. Only startup that is tricky. But again the MSRE had no major issues… using 1960s technology. I’m currently modelling a design that uses a pool of buffer salt that keeps the entire primary loop immersed in hot salt, preventing freezing and allowing easy passive decay heat cooling.

Douglas Wise: the spectrum of the fluoride salt cooled IFR would be fast, but not as fast as the sodium cooled IFR due to inelastic moderation of fluorine. This is possible with thorium, which can breakeven on breeding in any spectrum. It is also likely possible to breakeven on breeding using only uranium and a fluoride coolant.

The coolant would be based on NaF with either BeF2 or RbF as secondary to lower the melting point. So you have NaF-BeF2 eutectic or NaF-RbF. NaF-BeF2 has a melting point of 340 degrees Celcius, the lowest so I’ve been looking at this one.

The vessel is fairly easy, use Hastelloy N like the MSRE used. Per Peterson’s AHTR will also use this material in contact with fluoride coolants.

The cladding is the most tricky part of the system. MIT is developing a triplex silicon carbide cladding for PWRs that fits the bill. If it works then this concept becomes a realistic option with many advantages.

The nice thing about thorium is that some of the negative aspects can be used as an advantage with the right design. For example, the presence of U232 complicates fuel processing, requiring it to be done fully automated. But this will be done for pyroprocessing anyways, and it is actually an oportunity to improve the proliferation (divergence) resistance. It is almost impossibly to steal fissile from a hot cell.

The biggest inherent disadvantage of thorium, in my opinion, is the lack of a fissile isotope. This requires a fissile starter material. The best material is plutonium. Low enriched uranium is also possible, but requires a high enrichment (because most of the fertile needs to be thorium it leaves little uranium which then needs a high fissile percentage to get a reasonable fissile loading).

Here’s an example of a fluoride cooled fuel rods reactor, the HEER reactor system:

https://www.ornl.gov/fhr/presentations/Feng.pdf

This one also uses NaF-BeF2 coolant and SiC cladding, and pool type design with a supercritical CO2 power cycle.

Cyril: Plenty of high-activity fission products to keep the system hot? I guess that would depend on the rate of cleanup chosen for the core and blanket circuits, and the immediate past history of power production. Also, one would have to be careful to ensure that the FPs are evenly distributed in the salt.

The last sentence in your second-last paragraph indicates that you don’t think proliferation is an issue for either IFR or LFTR. I think some skeptics in the Administration will have to be convinced.

Short- and medium-term reactivity control in LFTR seems to depend on the rate of extraction of the protactinium. I would pray for a very highly reliable and steady extraction system, if that is the case.

Chris:

But is thermal efficiency a primary consideration? I think not.

Readers may not understand the relevance of the critical point of water, which is 647 K (374 °C; 705 °F) and 22.064 MPa (3200 PSIA or 218 atm).

Above that temperature and pressure, water behaves differently than below it, because it does not exist as a liquid and it is thus possible to obtain greater operating efficiency due to lower losses, especially condenser losses.

Supercritical points for other fluids can be found on-line, eg at http://en.wikipedia.org/wiki/Critical_point_%28thermodynamics%29.

Supercritical operation is a good thing from a thermodynamic point of view because it enables higher efficiencies – more electricity for the same input heat energy. This comes at the price of increased operating pressures and temperatures, hence possible higher capital cost.

One impact of Chris’s point is that water can be used as the fluid which carries heat from the boiler to the turbine. Candidate designs which use other fluids – lead, sodium, helium, etc – need to manage risks associated with those fluids, whereas steam, if it escapes, is water vapour, the risks of which are very well understood.

Water is also cheap and plentiful.

If Chris is suggesting that water is better than some other candidate fluids and that supercritical operation is desirable, it may be on the basis of lower cost, safety and efficiency and because we have knowledge gained from the many thousands of water boilers in service worldwide, a percentage of which operate in the supercritical range. I agree, but only to the extent that these impact final cost expressed as LCOE and public/regulatory perceptions of risk.

A final note on efficiency was provided by G Stanford, above:

I agree. Chasing efficiency when the raw cost of fuel is low is not important, because it will have minor effect on LCOE.

Caution: I am not an expert in thermodynamics. Have I overlooked any significant other factors?

@Dan Meneley on proliferation … “reactivity control in LFTR seems to depend on the rate of extraction of the protactinium” – did you really mean “extraction”?

Sure, after an LFTR powers down, the transient Pa 233 (that was near equilibrium with the previous rate of creation and fission of U 233) will continue to decay and increase the reactivity. It would be an automatic process to remove or dilute the fertile salt that remained in the core to ensure that its reactivity could never reach criticality.

However moving some of the salt outside of the core would be enough. If an LFTR installation was found to be taking the extra step of extracting Pa 233, there would indeed be a proliferation concern as any protactinium isolated would decay to highly enriched U233.

Roger: It is my understanding that, in order to sustain a conversion ratio of 1.0 or above, the LFTR must remove protactinium from the circuit, more or less continuously. The decay product, U233, is returned to the circuit after an appropriate delay.

Am I wrong?

Yes Roger, he means extraction of Pa-233 and out-of-core decay to U-233, this is how the proposed LFTR fuel cycle works. The question I guess is the purity of the removed salt, as you say.

Could someone explain to me, as a lay-person, the advantages of both the LFTR and the IFR over advanced CANDU reactors (or point me in the direction of some good reads on the matter)? I’ve read numerous times that CANDUs can run off of natural uranium, thorium, and even “burn” weapons grade plutonium.

Are there any operational CANDUs which are using thorium as a primary fuel source now? Why is the LFTR considered so important if CANDUs can already use thorium as a fuel?

And what are the advantages of the IFR over the CANDU, if CANDUs can use natural uranium or plutonium as a fuel source? Does the IFR have a higher burn up rate/fuel use efficiency?

And how do costs (or projected costs) compare?

I assume that if either the LFTR or IFR has more advantages over existing CANDUS than the other, that would give that reactor a competitive edge.

@Dan, Barry. A thorium MSR design can ensure maximum conversion ratio by “removing” (which Dan may actually have meant by saying “extracting”) occasional bucketloads of salt from the core, replacing it with bucketloads of salt which had been sitting out-of-core for a few months. (Where xenon is removed at the pump, fission product cleaning might be quite infrequent, if at all).

On the other hand, it would worry the proliferation people, if pure Pa 233 were chemical isolated, and then deliberately accumulated until it had decayed to highly enriched U 233. The extra process seems unnecessary, expensive and requiring levels of radiological control and security unwelcome in a power station. Am I missing something?

Tom: Yes,the CANDU can operate on natural uranium, slightly enriched uranium, RepU, MOX. Further it can run as a “near breeder” with top-up of fissile material, either U235 or Pu. None of the 30-something operational CANDUs are now operating on thorium as a primary fuel source. Both India and China are well along on the development pathway to that goal. (In Canada and other countries the simplicity of the natural uranium cycle has, so far, won the day.)

However, the fraction of the original potential energy that can be extracted by CANDU is only a few percent — running on a natural uranium once-through cycle it extracts 0.75 percent – only about 25% more than a PWR. So long as one has a goodly supply of cheap natural uranium, all is well. In the long-term future however, especially as the demand for nuclear energy expands by 1-2 orders of magnitude, uranium will become expensive (thorium too). The then-existing world fleet — mainly water reactors — will require a steady flow of economic used fuel.

It is prudent, therefore, to develop advanced reactors that can assist CANDU and other thermal reactors to sustain operation as uranium prices rise — at least over their expected 100-year life span. It also is prudent to do so in order to reduce the hazards and volume of “used fuel” discharged from those older reactors, and that must be stored for a long time.

The prime candidate for this duty is the SFR, especially the design known as IFR. This new IFR fleet will be able to utilize all of the accumulated used fuel from thousands of thermal reactors and extract about 100 times more energy from each ton. At the same time the final used fuel from the SFR will be much easier to manage than is the thermal reactor used fuel.

Personally, I am not sufficiently knowledgable regarding the LFTR to say whether or not they will be able to produce a sufficient amount of excess fissile material to sustain the older thermal reactor fleet — I suspect not. In addition, I doubt that they will be able to “dispose” of the accumulated used fuel from the older thermal reactors, at least as efficiently as the SFR can. These two tasks are “must do” assignments for any advanced reactor, in order to justify its development costs.

Capital + operating costs of CANDU reactors today are comparable to those of LWRs, based on recent experience in China. Future costs of all “fleet capable” units will decrease slowly as technology and experience is accumulated. I have no firm data, of course, for the IFR or the LFTR.

Best regards

Dan

Roger: Certainly, that is how a “normal” operator would operate. However, the first assumption of the safeguard folks is that the plant owner (a national government) has a deliberate plan to produce illicit weapons-grade material. Cost is no barrier.

I understand that there would be some degree of protection afforded by the small amount of high-activity U232 that will be present in the protactinium stream.

If I understand this correctly this seems to be saying Australia may never need a uranium enrichment industry if it takes the CANDU->IFR path, apart from imported start charges that is. Australia will soon produce as much thorium as uranium purely because of demand for zircon and rare earths, not as nuclear fuel.

This is a setback to those who were hoping the AP1000 could be built in Australia somewhat closer to the Korean price. It locks us in to one particular Gen 3 manufacturer so we don’t get to shop around.

Dr. Meneley,

Thanks very much for your response, it clarifies well my questions, and your framing of the two “must do” assignments to justify investment in advanced nuclear power is a compelling argument for IFR development.

Please bear in mind there are several types of LFTRS. The workhorse is the single fluid “Converter”, the breeders are usually dual fluid.

The single fluid version was the one actually built and tested for about 5 years.

Tom Keen, in the paper “Transition to Large Scale Nuclear Energy Supply“, Dan Meneley has gone over the CANDU/IFR scenario is some detail. It is really worth reading. Here is a snippet:

This article mentions the ‘energy amplifier’ as an alternative to the LFTR

http://www.smh.com.au/environment/energy-smart/thorium-pushed-as-uranium-alternative-20111106-1n1z3.html

The mining companies that would benefit from increased local thorium demand appear to be

Lynas – mine in WA and extraction plant in Malaysia

Iluka – mine in SA concentrate sent to WA, currently stockpiled

Arafura – mine in NT, extraction in SA.

Generally the mining companies that are mining zirconium, titanium, and the lanthanide elements such as Iluka and Lynas want to try and find mineral deposits that contain the minimum amounts of U and Th because they don’t want to get caught up in the political and regulatory headaches associated with “uranium mining”, “radioactive waste” etc., because they don’t consider those headaches to justify the value they might get from producing a small amount of processed saleable uranium oxide, and the demand for Th at the present time is very low.

I would be very interested in hearing what Martin Ferguson and Martin Hoffman have to say about nuclear energy at this upcoming thorium nuclear energy conference in Canberra.

@John Newlands: Personally I don’t see any value in the “energy amplifier” aka. accelerator-driven subcritical reactor.

You need a very large, very powerful particle accelerator (something roughly on the order of 10 mA of proton beam at 1 GeV, so about 10 MW of accelerator power) driving the reactor (the reactor is cooled by Pb-Bi eutectic, which acts as the neutron spallation target for the proton beam) and adding this very large particle accelerator to your fission reactor obviously adds a lot of complexity and cost.

But what’s the point of all that added complexity and cost? What justifies it? What does the accelerator give you that an IFR or LFTR or Pb-Bi cooled fast reactor does not already give you?

Basically nothing, as far as I can tell.

Dan Menely wrote:

Processing out the fission products doesn’t make the heat go away – that’s the fundamental challenge with the fission products. But we can use this to our advantage. Either process online and let the decay heat warm up the hot cell (oven) elsewhere, or don’t process and run as converter reactor (a DMSR) which leaves the decay heat in the fuel. Either way you can design for this heat to keep everything in liquid state even during extended shutdowns.

One idea I have is to just make the hot cell thermally leaky so that it always loses some heat, based on thermal emissivity, the hotter it gets the more heat it loses. That’s a guaranteed decay heat cooling system. If it gets to cold during a shutdown the thermal emissivity drops exponentially. That prevents freezing during extended shutdowns. For really long shutdowns you’d eventually need supplementary electric heating or let the stuff freeze in a dump tank.

I’ve suggested to put the entire primary loop in a bath of buffer salt which shields the radiation and is a heat buffer for transients.

There wouldn’t be any fission products of significant quantity in the coolant for this system… its a fluoride cooled IFR. For a LFTR with fuel in the salt, the stuff that wants to stay in the salt stays there and the noble stuff – gasses and metals – come out easily in simple sparging and particle spunge filters. Oak Ridge ran the molten salt reactor experiment very successfully for several years and was able to solve all the operational issues. They were getting ready for a large scale demonstration when the funding was cut for political and budget reasons.

It’s not the case. The equilibrium Pa233 concentration in the system is very small, and one can easily make do without any Pa seperation while still breaking even on breeding. This is done simply by lowering the power density – the slow decay constant of Pa233 being sensitive to power (flux) density.

It goes without saying that the processing plant should be able to shut down without the reactor powering down, for reliability/economic reasons. This is not very hard since any practical processing will be slow (months to years).

Dan Menely wrote:

I strongly disagree with this line of thinking, for several reasons.

By the time LFTRs are developed the exisiting thermal burner solid fuelled fleets will be older than cranky.

Moreover, in the grand scheme of things, the existing nuclear plants are almost completely unimportant. We need at least 10000 GWe, and probably more like 20000 GWe, of nuclear new build to solve the CO2 emissions problem adequately in the future (growing energy demand). What’s 500 GWe of existing capacity in that scenario? It’s nothing.

Besides, there’s plenty of mineable uranium available at high energy return, the stuff being log normally distributed in the earth’s crust.