Guest Post by Peter Lang. Peter is a retired geologist and engineer with 40 years experience on a wide range of energy projects throughout the world, including managing energy R&D and providing policy advice for government and opposition. His experience includes: coal, oil, gas, hydro, geothermal, nuclear power plants, nuclear waste disposal, and a wide range of energy end use management projects.

[Ed: Peter is seeking feedback. Some reviewers comments he has already received are given at the end of this document, for reference.]

Pumped-Hydro Energy Storage – Tantangara-Blowering Cost Estimate

Introduction

Energy storage is essential for intermittent renewable energy generation and is valuable with coal and nuclear generation too. Pumped-hydro is a mature technology and is generally the least cost option for large scale energy storage.

This paper provides a rough cost estimate for a pumped-hydro energy storage facility that would utilise existing dams and reservoirs in the Australian Snowy Mountains Hydro Electric Scheme.

The paper is in response to questions about the cost of pumped hydro energy storage, especially as a component of a fossil-fuel-free electricity generation scenario for Australia. The paper is the fourth in a series of articles (see here for a listing — search this page for articles authored by Peter Lang).

Project Description

The proposal is to build a 9 GW pumped-hydro facility by connecting two existing reservoirs with tunnels, pipes, generators and pumps.

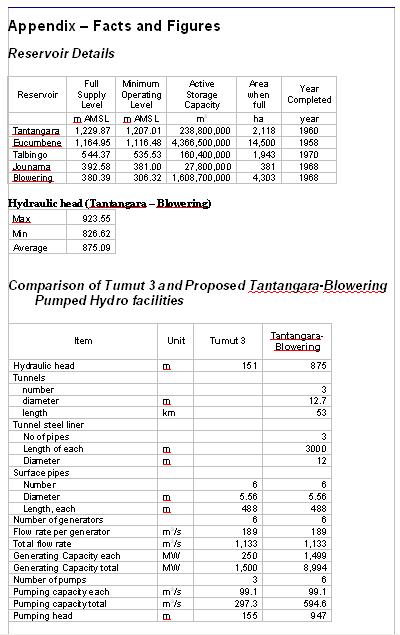

The two reservoirs are Tantangara (the upper reservoir) and Blowering (the lower reservoir). The difference in elevation between the water levels in the upper and lower reservoirs is 875m (see Appendix). The tunnels to join the two reservoirs would be 53km long (Figure 2).

The facility would generate 9GW peak power, for 3 hours per day from 6 hours of pumping at full pumping rate. It could generate for longer at less than 9GW, or if pumping was for longer than 6 hours per day, or if the pumping rate is greater than assumed in this analysis.

The proposal is to bore three tunnels, each of 12.7m diameter, to link the two reservoirs. The reservoirs would be tapped near their down-stream ends to maximise the volume of water storage available. About 3km of the tunnel at the lower end would be steel lined to prevent leakage. There is just about sufficient ground cover along most of the remainder of the tunnel route to avoid the need for waterproof lining or grouting for most of the remaining 50 km of tunnel.

The rocks to be tunnelled through would be mostly granite and similar strong, hard igneous rocks. There may be some hard sedimentary rocks, possibly including minor amounts of limestone. The rock would be fractured and faulted.

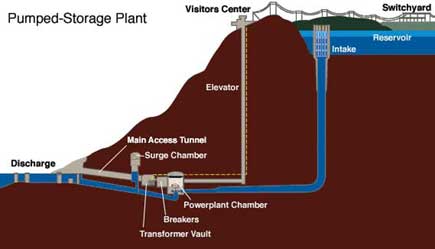

The power station is assumed to be similar to Tumut 3 in that it would have six turbines in a power station of similar size to Tumut 3. The differences are that the power output will be six times that of Tumut 3 (because six time the hydraulic head). There would be six pumps rather than the three at Tumut 3. Another difference is that some 3km of steel lining will be required in the tunnels.

Issue – Francis turbines, which are best for pump storage, currently have a hydraulic head limit of about 600m. Tantangara-Blowering is 875m hydraulic head. The manufacturers are working on increasing the upper limit. I understand manyufacturers are working at the moment to double them up.

Issue – Francis turbines, which are best for pump storage, currently have a hydraulic head limit of about 600m. Tantangara-Blowering is 875m hydraulic head. The manufacturers are working on increasing the upper limit. I understand manyufacturers are working at the moment to double them up.

Cost Estimate

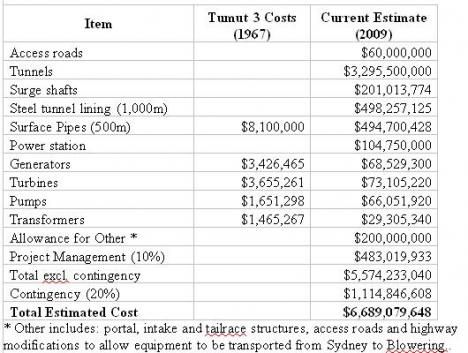

The table below provides a ball park cost estimate for the scheme. The tunnel costs, the main component, were calculated using costs for rock tunnel excavation from world wide experience. The power station, pumps, etc, were estimated by multiplying the original costs (from 1967) for Tumut 3 by 10 (that is approximately how much inflation between 1967 and 2009), and by doubling the cost of this equipment to allow for the six times greater water pressure and, therefore, power output. The greatest uncertainty is the cost of the steel pipes, tunnel lining, power station and ‘Allowance for Other’.

How realistic is this cost estimate?

World experience is that hydro projects cost about US$2,000/kW to US$4,000/kW. The Electricity Storage Association gives a range of costs for Pumped-Hydro of US$500/kW to US$1500/kW. This project is A$744/kW.

So the proposed Tantangara-Blowering facility is towards the low end of the range (if the figures are correct). The main reason for the lower than average cost is that the reservoirs do not have to be built; they already exist. However, this project requires more tunnelling than is normal for pumped-hydro facilities.

Conclusions

The Tantangara-Blowering pumped hydro scheme would be a high capital cost investment for just 3 hours of peak power generation per day.

This is the most economic of the four projects investigated.

Pumped hydro is often economically viable for providing peak power for a system comprising mostly fossil fuel and/or nuclear generation (France’s system is the ideal example). But pumped hydro is not well suited to intermittent, unscheduled generators.

I would like to acknowledge the help of some friends, all of whom have had a life time of experience working on hydro-electric projects around the world (all but two still are). Our work on hydro sites and our friendship go back 39, 33, 33, 29, and 19 years. I would like to thank Rich Humphries and Dr Derek Martin for their invaluable assistance (and for taking time off from catching neutrinos to help me: they are building a large underground cavern deep below Sudbury, Ontario to catch neutrinos that will be beamed through the rock from Chicago); Tim Little (Canada), Andreas Neumaier (currently in Asia) both of whom have a life-time of experience designing and constructing hydro-electric projects; and David Purcell who was the first boss I had who could influence me. He grew up in Cabramurra, the construction camp for the Tumut 1 and Tumut 2 projects in the Snowy Mountains Scheme. On weekends he would go with his father, a civil engineer, around the scaffolding and walk-ways as he checked out the construction work and instrumentation on the Tumut Pond concrete arch dam, Tumut 2 Dam and the Tumut 1 and Tumut 2 underground power stations. What a way to start a life. Certainly, today’s young can’t get that sort of early experience of the real world.

Pumped hydro is an excellent match for nuclear and for dirty brown coal fired power stations (because they run at full power all the time and produce very cheap power). Consider the 2007 NEM demand: Peak = 33GW, average = 25GW, base-load = 18GW. Option 1 – nuclear only. 33 GW @ $4b/GW = $132b. Option 2 – nuclear + pumped hydro. 25 GW nuclear @ $4b/GW = $100b + 8GW pumped hydro for $15b = $115b. Conclusion: Option 2 (nuclear + pumped hydro) is the lower cost option.

Reviewers’ Comments

Reviewer 1

I had a quick look at your idea of a pumped storage scheme between the Tantangara and Blowering resevoirs in the Snowys. I have only spent a couple of hours looking at your numbers for the assessment of the technical and economic viability of such a scheme. It is my personal view as an individual and not that of the company I am working for.

Ok, here comes the technical side:

1. One would have to assume that the available head is between the minimum operating level at Tangagara, MOL = 1,207 and the full supply level at Blowering, FSL = 380 because any operator would have to guarantee 95% reliability for his peaking power. Thus, the gross head for power generation is MOL – FSL = 827 m

2. Assuming 3 No.s tunnels of diameter D = 12.7 m gives a cross sectional area of Atot = 380 m2.

3. Assuming a maximum flow velocity of v = 3 m/s to keep friction losses within a reasonable range, the total discharge Q = v * Atot = 1,140 m3/s.

4. With that and assuming a local and friction loss factor of η = 0.85, the energy P computes to be P = 7,860 MW using the formula

P = (9.81*η*Q*H)/1000

5. Assuming an operating time of T = 3 hours/day the available energy is E = P * T//1000 = 8.6 GWh/year

6. The discharge volume V = Q * T * 3,600 = 12.3 106 m3.

7. With a reservoir area of Ares = 2,118 ha and assuming vertical reservoir walls, the drawdown over the 3 hour operating period will be Δh = V/Ares = 0.6 m which is acceptable from an environmental and safety point of view, I think.

8. Assuming that the operator can sell peaking power at 4 times the rate as he has to buy the power for pumping during off-peak times, say $0.60 generating vs $0.15 pumping costs, the annual revenue from the scheme would be R = ($0.60 – $0.15) * 8.6 106 = $3.87 billion per year.

9.I am not a mechanical engineer but I believe that at a head of H = 827 m you are pushing the envelope of what turbines can take. I also think that you may need more than 3 units, say 6 or 9 to keep the size of the turbines and pumps and the width of the underground cavern to a reasonable size.

Now comes the project cost sides:

1. The tunnel is by far the most expensive single item so I have focused on that. I do not have a price for a 53 km long, 12, 7 m diameter tunnel excavated by TBM so have used a 8 km long, 3.5 m diameter tunnel and scaled it up to give an approximate figure for the bigger tunnel. Assuming that the tunnel will be mostly unlined and constructed in essentially sound rock, the costs for excavation, support and care of water during construction is $ 7.56 109, which more than double your figure.

2. You have scaled up the 1967 costs of T3 to arrive at the other major cost items. If my tunnel cost figure is correct, I fear that the other cost items may also be higher than what you have estimated.

3. If this is the case, the construction costs may be closer to $15 billion than $7 billion as you have estimated, which will bring the cost per installed kW back into the range of $2,000/kW which is about what pumped storage schemes cost these days.

I do not mean to discourage you but the capital expenditure for a pumped storage scheme between Tantangara and Blowering seems prohibitive because of the scale of the investment, the high up-front costs and the long period for investors to recover their money. Unfortunately, politicians and banks take a much shorter view of life when it comes to political or financial gains and it seems to me that your idea, as much as I like hydro, seems to be condemned to the ‘not economical’ basket.

Reviewer 2

I took a quick look at your costs and determined that it would take more time than I have to review those adequately. We have had a lot of challenges with cost escalation over the last several years (until the last year or so) and I would not want to give you a misleading opinion. That said, I do have some quick comments on your proposal:

– The proposed capacity of 9GW (9000 MW) is huge. Compare to Itaipu (12,600 MW), previously the world’s largest hydro plant and now Three Gorges (ultimately about 22,000 MW) or Revelstoke (2000 MW, soon to be 2500 MW when Unit 5 is completed).

– The proposed number of turbines is 6, which translates to 1500 MW each. I believe the world’s largest turbine capacity to date is about 750MW. (e.g. the turbines at the Sayano-Shushenskaya dam in Siberia which recently experienced the world’s worst hydro plant disaster to date – check it out on Google if you are not familiar already).

– The head is very high as you note. I believe Francis turbines have been built for heads as high as about 800m, but probably not for large capacity.

– Your overall cost looks quite low at less than $800/kW; as you note, world experience is typically several times that today.

– Your stated uncertainty of 25% is too optimistic. When we do a conceptual level estimate by a qualified estimator, we state that the uncertainty on the upper end is as high as 100%. The uncertainty goes down as more design is done, and we would not claim 25% uncertainty until we were into final design.

– Steel lining is one of the more critical cost factors. For many high head projects, the cost of steel lining is the factor that determines whether the project is economic or not. You need to know in situ stresses etc to do a proper analysis.

Filed under: Nuclear, Renewables

.png)

Thanks for this analysis Peter. Very interesting.

Given that even if tyhe impediments to rolling out nuclear power disappeared tomorrow, we would be burning gigatonnes of coal before dispensing with the last coal plant in favour of the latest nuclear plant, even if the total did come to $132 billion for the combination NPP + pumped storage it would probably still make sense.

After all, if one can reduce the CO2 intensity of coal and gas by judicious management of coal and gas plant operation that’s still an advantage. If less redundant capacity for the renewables we are going to have is needed then that too is an advantage.

And of course, our total stationary energy demand by 2030, 2040 and 2050 is bound to increase, especially if significant transport capacity is on grid, so the facility is hardly likely to be wasted.

Peter – Excellent post, thank you.

I wonder if you could explain your conclusion “Pumped hydro is … not well suited to intermittent, unscheduled generators” in a little more depth, as this wasn’t really discussed in the body of the paper. I assume this is because (in this example) it can only generate peak power (9 GW) for 3 hours a day, which is problematic when considering total density and volume of electricity in a grid powered by intermittent sources, but I’d be keen to understand it properly.

Cheers.

115 billion dollars is a very large amount of money. Is spending that much, even over a number of decades, even in the realm of possibility? I ask because this is mostly discussion from an engineering perspective, however that is not something the public is interested in. How much will it cost the average Australian? Apologies if these questions are too much in some way or another.

Thanks.

Teekay

I think its more a question of the fact that the pressure in pipes has to be maintained by a constant and steady supply of power to the pumps over several hours. Intermittent sources by definition can’t meet this standard.

Scott asks:

Well if we are talking 30 years, for example, that’s less than 4 billion per year or less than 0.4% of GDP. By way of reference, the government is negotiating over a submarine contract which is going to cost between 25 and 40 billion dollars. The national broadband network fund is $43 billion (most of it private but the government is backing the project funding).

So the money is there and in the end, the bulk of it is for installed energy production assets that have to be built. Those coal and gas plants have to be replaced sooner of later and in the end, someone will pay.

On the income side on both coasts of the country a number of massive LNG projects have just been announced probably beginning 2015 the revenue from which will dwarf the sums we are talking about here.

Ewen @ 5 April 2010 at 19.11

I am not quite clear what you are asking or stating in this first post. I’ll try to answer, and please ask again if I’ve misunderstood.

You are correct that demand will increase and it will take at least 30 years, probably longer, to replace all the coal fired power stations. This papers shows projections of demand and the replacement of coal generating capacity with other options between 2010 and 2050. http://bravenewclimate.com/2010/01/09/emission-cuts-realities/

Pumped hydro will not reduce the CO2 emissions intensity. It actually increases it because the efficiency of the pumped storage system is about 7%5 to 80%. So we need to burn say 5 tonnes of coal for pumping and then we get the energy equivalent of only 4 tonnes of coal when we generate from the pumped hydro. Gas generators would not be used for pumping because gas is far too expensive; similarly with wind and solar, even if they could provide reliable constant power in the early hours of the morning. Coal and nuclear are ideal for puimp storage because they produce cheap power in the early hours of the morning when demand is low. So there is no demand for the power from hydro and little other demand for the power from the coal fired generators.

The $132 billion figures was for the all nuclear option to replace all the current generators in the NEM. The alternative with 25GW nuclear and 8GW hydro would cost $115 billion. So this option is cheaper. (reserve capacity margin ignored in these figures for simplicity). I doubt pumped hydro is economic in Australia at the moment. Gas can do the job more cheaply and with less emissions than using brown coal (the cheapest) for pumping.

Does this address your points?

TeeKay, on 5 April 2010 at 19.35 Said:

I had intended to rewrite the paper after the reviewers comments and also address your question. But never got around to it. Thisew who were following the discussions with Neil Howes last year, will recognise that this paer stemmed from those discussions.

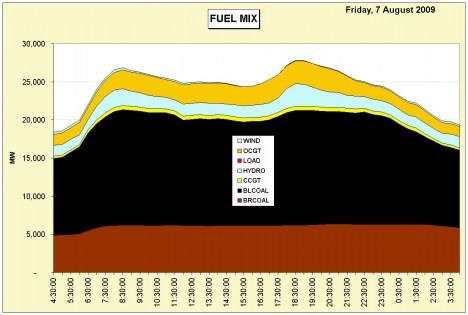

Hydro is an excellent mix with intermittent renewables because when the intermittent renewables are generating the hydro does not, so it saves its stored energy (the water stays in the storage reservoir for future use. But this is not the case with pumped hydro. With pumped hydro we need constant, reliable power when the demand on the grid is low. That is from about midnight to about 6am (refer to the last chart in the article above and not the time of low demand). So for this reason alone solar and wind power are totally unsuited to pumped hydro.

But there is another reason to. As the Reviewer # 1 above pointed out, the power for pumping needs to be purchased at about ¼ the price the power will be sold. Wind power costs about $110/MWh and solar abour $250/MWh, where as the baseload power from coal in the early hours of the morning is probably around $30/MWh. So wind and solar power (and gas) are too expensive for pump storage. The power from pump storage would be sold at peak power rates. (readers will appreciate I am simplifying everything here).

Scott, on 5 April 2010 at 19.44 Said:

Scott, I think you may not have seen this paper: http://bravenewclimate.com/2010/01/09/emission-cuts-realities/

It is an important background to all these discussions.

The spending of $115 billion would be over the period 2010 to 2040. However, if we didn’t have to spend it on nuclear, we’d have to spend it on replacing the existing coal fired power stations either with coal or with gas. We would need to spend about $2 billion per year for 40 years if we replaced with coal. So the extra cost is about 35 billion for nuclear and gas over a period of 40 years. The paper above shows the projections of capital expenditure, capacity of each technology, CO2 emissions, and electricity cost (for the substitutions) for six technology mix options (coal, gas, nuclear, wind and solar).

As Ewen pointed out, to put tthe $35 billion extra expenditure over 40 years in perspective, we have committed to a federal debt of $200 billion in the past year, spent $3 billion on pink bats insulation and committed to $43 billion for a national broadand network (mostly private sector funding is hoped but that is unlikely to happen).

By the way, I just noticed. Barry has been very cunning. If you click on the photo of the Tumut 3 power station, it takes you to a satellite view of the project and several other photos,

Thanks for your response Peter, that makes sense to me now. I appreciate the simplification too.

As far as I can tell there’s also no way pumped hydro could complement the renewable-only advocate’s notion of “efficiency” as a solution, as the process would have to be an overall net consumer of energy. It just makes good economic sense, in terms of peak revenue, if you have reliable baseload generators.

Good article Peter. For the sake of reference what sort of continuous output could this project deliver with the water inventories it collects from the natural catchments?

Pumped hydro certainly has a place but this idea looks to be in the engineers pipe dream class.

Apart from all the technical and cost problems it is just way too big and centralized which exposes the grid it feeds to reliability issues.

One issue could be water.I was at Tantangara Reservoir last year and it was virtually empty-below the tunnel outlet to Lake Eucumbene in fact.

Australia would do better to concentrate on smaller,dispersed generation,not mega projects.

An alternative approach might be to deliver unregulated electricity from nearby to dedicated pumps at the discharge area. The water is simply sent back uphill to the lake in a short steep pipe, no tunnels or major concrete works needed. The motors would be variable speed and the pumps would be positive displacement such as helical rotor. I have no idea how much it would cost or the round trip losses.

If Tasmania had the export capacity several dams would suit this approach. There are two vacant slots for 150 MW Francis turbines at Gordon Dam, suggesting river flows didn’t meet expectations. The King and Pieman catchments are very close to the windy west coast. Maybe there is 2 GW in it at unknown expense including building a second underwater HVDC cable for export. In reality Tasmania now imports more and more coal fired baseload electricity from the mainland since the existing cable was built. For the zinc, steel and aluminium electrorefiners it is a case of ‘out of sight out of mind’.

I misled readers in my post at 5 April 2010, 22:03.

The $35 billion extra is the additional cost to build 25 GW of nuclear and 8 GW of pumped hydro instead of replacing the retiring coal power stations with new coal. However, this does not take into account the demad growth. 25 GW was the average demand for 2007 and 33 GW the peak demand in 2007. The demand will increase over the 30 to 40 year replacement period, so obviously more cpacity will be required and this will cost more than the $35 billion I mentioned in my previous post. Based on the assumptions in the paper here http://bravenewclimate.com/2010/01/09/emission-cuts-realities/, (such as high cost nuclear), Figure 9 shows that the extra capital expenditure, cumulative to 2040, would be about $80 billion ($180 billion for coal and gas instead of $100 billion for coal). Figure 8 shows the projected capital expenditure per 5 years from 2010 to 2050. Divide the capital expenditure in Figure 8 by five to get the annual capital expendityre. Subtract the capital expenditre for BAU (Business as Usual) from ‘Nuclear & Gas’ to get the additional capital expenditure that is due to building nucear and gas instead of new coal.

DV82XL, on 6 April 2010 at 1.23 Said:

That is a complicated question. Here is some of the answer.

The upper reservoir Tantangara) is the smaller of the two. If it was full, and if there was no restriciton on the rate of drawdown, it could run at full power (9GW) for 58 hours. Great in an emergency where the grid goes down. That was the easy part to answer.

(As an aside, one of the really great things about hydro is it can restart the grid from scratch if there is a total failure).

Now for the harder part. Tantangara’s role is to capture water in the headwaters of the Murrumbidgee River and divert the water to Eucumbene, which is the Snowy Mountains Scheme’s large, central storage reservoir.

Another aside – (I love this stuff) Eucumbene is the key to the Snowy, and a great story in itself how it came to have this role (thanks to Sir William Hudson, a highly regarded consultant from the Tenesseee Valley Authority and a long horse back ride around the scheme in the early 1950s).

Water transferred from Tantangara to Eucumbene falls some 100 m without generating electricity. Then it runs down through three power station (Tumut 1, 2 and 3) to Blowering Reservoir.

This is going to get too complicated to explain here. The short answer is that I have based the scheme on pumped hydro only and no generation from the normal inflows to Tantangara. The economics of the scheme would be improved by using some of the Tantangara catchment water for generation. How much would be an economic decisions and a whole stack of other factors.

Teekay

Dead right. Well summarised. You’ve got that in one. Please explain it to Mark Diesendorf and Mark Jacobson. 🙂

Podargus, on 6 April 2010 at 5.50 Said:

I agree. It is not viable. I wrote this up because greenies kept bleating about how much pumped hydro storage capacity was available in existing dams in the Snowy Mountais Scheme and elsewhere. They keep raving on about how “we can have masses of cheap pumped hydro storage and Compressed Air Energy Storage available in existing dams. They reckon the problem is that no one takes any notice of them. So that is whay I wrote this up. And this is about the most economic scheme available. Anything else would provide more expensive electricity.

I presume you do realise of course that we don’t need to build the full 8 GW. We could build smaller amounts, built incrementally, and we could build similar but more expensive schemes elsewhere.

I presmue you did read right through to the Reviewers’ comments, since they said much the same as your comment.

The reason you saw it empty is because Tantangara’s role is to divert all its water to Eucumbene. It needs to be enpty before the seasonal inflow season starts so it can capture as much of the seasonal inflow as possible. But this is irrelevant to the pumped hydro scheme because the pumped hydro uses only the water pumped up from Blowering. The water level in Tantangara Reservoir would rise and fall by about 0.6 m each day (when the reservoir is full, more when empty).

No that is wrong. Distributed systems are far more expensive. Probably orders of magnitude more expensive.

The so called distributed wind and solar systems are EXTREMELY centralizing and very susceptible to common-mode failure.

Here is the aggregate wind power production of the entire nation of Germany: http://i47.tinypic.com/8xjuw6.jpg

It acts not as tens of thousands of individual turbines; it acts like a single unreliable 25 GW generator.

What is the typical solution offered to this problem by self-professed greens? They range from build a massive pan-european grid and intricately coordinate the various countries rather than the loose coordination of today to building weeks of electrical storage at massive centralized facilities.

What’s the solution taken by Germany in reality? Build a big gas-pipeline to Russia.

The decentralization of “renewables” is a mirage.

Why not connect talbingo->tantangara (which is much closer at ~20km)?

Hi Dashpool,

That is a really good question and it was discussed at length on another earlier thread.

The main reasons why I did the analysis on the basis of Tantangara Blowering (T-B) rather than Tantangara-Talbingo (T-T) are:

1. The greater hydraulic head difference (that is the difference in elevation between the water levels in the top and bottom reservoirs), and therefore more power available from T-B than T-T (see the Reservoir Details in the Appendix).

2. Talbingo is maintained near full to maximise the head for generation in Tumut 3. The operators manage the level in Talbingo by controlling the rate they release water from Eucumbene and down through Tumut 1 and Tumut 2 to Talbingo. They also have to keep enough storage space in the top of Talbingo to hold the water Tumut 3 pumps up at night (Tumut 3, as you probably know, is a pump storage facility itself). So, without knowing much about the operating constraints, I guessed that running another pump storage scheme using Talbingo might compromise the overall efficiency and flexibility of the system.

I actually did a rough comparison of power, storage and cost for four options:

1. Enlarged Tumut 3 including pump back from Blowering

2. Eucumbene – Talbingo

3. Tantangara – Talbingo

4. Tantangara – Blowering

Tantangara Blowering was the most economic based on my very rough calculations. However, as the two reviewers pointed out, I probably underestimated the cost by a factor of 2 or so, so a more expert analysis might find your proposal, Tantangara Talbingo, to be a better proposition. If you are able to do this comparison, it would be great if you could post it here.

Well, I would be interested to see why your Tantangara – Talbingo was relatively expensive.

Basically, the head is ~720m instead of 875m, so not so much different. For same flow rate, 6.5GW instead of 8GW.

The tunnels would be ~20km long instead of 53km long. Assuming the flow rate is limited by losses inside the tunnels, it would be reasonable to use two tunnels instead of three to get the same proportional drop in head due to friction losses. (a quick calculation gives losses of the order of a couple of percent one way)

I can’t figure out what cost methodology you used for the tunnels, but assuming

the cost is proportional to volume excavated, this would reduce the cost of the tunnels by almost a factor of four. As the reviewer points out, your tunneling costs seem low compared to comparable projects (e.g. Gotthard base tunnel per unit volume).

Since almost all the major cost items are proportional to tunnel cost, this would seem to massively reduce the cost of the project. The sides of talbingo and blowering are pretty steep, so 1km seems adequate for lining. $250,000/m should buy quite a lot of steel. Rougly adjusting your figures, the cost would be about 3.5 billion dollars instead of 6.7 billion.

I don’t know what the interoperations with tumut 3 would involve: this might be inside the margin of error for a project of this scale.

Hi dashpool,

I can see from this post that you do know quite a lot about the subject. I’ll give you some quick responses now, but I’ll have to wait until after the weekend to look back at the four cost comparisons.

I agree.

No this is not correct. We’d still need to keep the flow velocity at about 2.5m/s so we still need three tunnels. I agree, therfore, that the cost of the tunnels would be roughly 20/53. The length of the steel lining would be roughly the same if the topography is the same at the down stream end. So we’d still need 3km of steel tunnel liner. This is a mjor cost item. The steel liner design is explained here: http://140.194.76.129/publications/eng-manuals/em1110-2-2901/c-9.pdf

The tunneling costs were determined from Figure 24 here http://www.rocscience.com/hoek/references/H2001b.pdf and escalated to 2010. However, I now understand that this does not include all the costs for such tunnels, hence the comments by both reviewres that I had probably underestimated by about a factor of 2.

No that is not a correct assumption. The power station and equipment will change little. The steel liner, a major cost item will not change in length, but the steel thickness will change by the reduction in hydraulic head. The tunnel will change by about 20/53 roughly and this is applied to roughly half the costs. The surge shafts will not change. Most items don’t change. Very roughly I see the cost of TT/TB = 75% and the power of TT/TB = 70%. This is very rough. Ialso think the constraints on managing the storage in Talbingo are not insignificant. Talbingo was designed to poperate with Tumut 3 and as part of the Eucumbene to Blowering generating and pump storage system. We cannot expect to make a mjor change to the top reservoir of Tumut 3 and not have a significant impact on the total system.

dashpool,

I would consider that Tantangara-Blowering would be in the order of $15 billion and Tantangara-Talbingo in the order of $12 billion.

By the way, I seem to recall (but may be wrong) that Talbingo did not have sufficent storage volume to make full use of the available storage capacity at Tantangara, So in the TT case Talbingo is the constraint, whereas in the TB case Tantangara is the constraint. That is from memory, I might have that wrong.

Dashpool,

I just realised I made a mistake in my quick calculation of the change in power. TT/TB = 82% not 70%. This swings the conclusion towards wht you are arguing. So I’ll have to look back at my original comparison. However, I don’t expect to be able to do so before Monday.

Woops again. I accepted your 720m hydraulic head for TT. It is actually about 670m. So the power ratio TB/TT = 76%. This is roughly what I expect the ratio of the cost to be also. But the TT option has major constraints on storage in Talbingo reservoir. So much so that I expect it would be less economic than TB.

Sorry to go off topic but I thought this was interesting. It suggests that maybe fusion is hotting up as an alternative in the not to distant future.

http://www.abc.net.au/news/stories/2010/04/06/2865472.htm?section=justin

Sorry about my mistake in the head calculation.

The TT proposal would involve a height change of ~0.7m on Talbingo (which has approximately the same area as Tantangara). This is less than a tenth of the working head range of Talbingo. Why do you think this would pose a major problem? I would have thought Blowering going up and down by 80m was more of a headache.

To elaborate on the number of tunnels question: as far as I understand, frictional losses can be approximated using the Darcy–Weisbach equation. Given the same Darcy friction factor (which is approximately constant at these Reynolds numbers) , pressure drop due to friction per unit length is proportional to the square of the mean fluid velocity.

So keeping the proportion of frictional losses the same as in your TB proposal, the TT proposal uses two tunnels, 25km long, with ~85% of the total TB flow rate. 968e3 kg /s *9.8 m/s^2 * 670m = 6.3GW before losses, 5.4GW electrical power assuming efficiency of 0.85. The fraction of head drop due to friction is 3,3% in both cases, which seems pretty conservative (Darcy friction factor 0.015).

Essentially the point is that steeper tunnels are cheaper, because you can afford more losses per unit length and have the same overall efficiency.

I recalculated costs, rescaling costs in your table according to the number of tunnels, electrical power, and tunnel length where appropriate. I use the maximum head for the TB calculation.

Tantangara-Blowering:

8.3GW electrical

$7,170,000 total cost

$862/kW

Tantangara-Talbingo

5.4GW electrical

$3,440,000

$636/kW

Of course, these are based on your cost methodology, but it seems to indicate that TT is better. Especially since the proportion of tunnel cost (which is very uncertain) drops substantially. (I’m having trouble getting your figures to add up exactly hence the slightly different value for TB).

Hi dashpool,

I still haven’t had time to look back at the comparison of the four options so I am working from memory as to what I did at that time (about July or August last year). TB worked out to be the most economic option using the assumptions I used at the time. However, the anlaysis was very simple. For example I used the same size power station and equipment for all the options. I now realise that I need to double the size of the power station because the maximum size turbine and generator set is 750MW not 1500MW as I had used.

I’ll have a look again at my earlier calculations for the four options, but not until Monday.

However, I certainly would not dismiss the effect of using Talbingo for the lower reservoir for a very large pumped-hydro facility while also using it as the upper reservoir for Tumut 3. There will be significant compromises, efficiency losses, and costs associated with that. If the TT project was clearly economically viable, it might be at the expense of Tumut 3.

But as I said, this did not enter into my earlier calculations but was in the back of my mind.

@Lang: Given CSIRO predictions for AU rainfall to move down the isotherms away from the equator over the next few decades, I am surprised to see a pumped hydro calculation for AU that does not mention this.

I cannot recall whether you are an AGW denialist or not, but your Snowy study here seems compatible with believing that precipitation in south-east AU is and will be constant.

As you know, Venezuela depends heavily on hydro and due to drought is running blackouts and brownouts at present; Ecuador is 40% hydro dependent and had them from ca. last October to Jan.

While I believe that the Snowy contributes only ca 3.5% to the national grid, it would seem strange to build an addition to it the feedstock of which is migrating to the Pole.

Hi again Peter,

I am not sure what the efficiency losses would be when operating Talbingo as a middle station between two pumped hydro schemes. It seems like both schemes would tend to be operating in the same direction (either both pumping, or both generating) at any given moment. As a result, the variation in the level of Talbingo would tend to decrease. In the case where only one scheme is working, the variation would be no worse than before.

If anything this would appear to make combined operation easier, because:

1) It softens a volume constraint (height of Talbingo).

2) It slightly reduces the head variation of both schemes, so that equipment can operate closer to nominal head.

Both of these effects should be small though.

I look forward to seeing your updated costings.

@TerjeP, they haven’t even been able to get D-T fusion working. Not even with a fissionable blanket which provides a free 10x amplification of the energy released. Not even in a subcritical fission reactor with the neutron source being fusion instead of spallation.

p-B11 is orders of magnitude harder. I would expect it to take at least several decades just for the laser technology to improve enough between achieving ignition for D-T fusion at a useful pulse rate(~1 Hz could be useful if you have a large fission component, probably about ~10 Hz to make the economics work without fission) to p-B11 becomming feasible.

It’s becoming apparent that rainfall variability not only affects farming but hydro as well in several continents. Parts of western Tasmania got over 3 metres or 10 feet of rain last year I believe. This year I think those same areas have had less rain than Alice Springs. Assuming evaporation is minor it seems logical to utilise the sunk costs by looping the water flow in drought years. That is the river is almost dry but the dam stays full due to re-pumping. That also assumes the capital cost per watt is competitive.

If this volatility is systemic we might get a repeat of those times when peaking hydro was unable to prevent rolling blackouts in southern cities.

http://www.abc.net.au/news/stories/2009/01/30/2478497.htm?section=australia

The water was in the dams but the converters overheated on the Basslink cable. Next time the converters may be OK but the water won’t be there.

Another example of how climate change and population growth double up but the guvmints can’t see it.

John Newlands and Peter Lalor,

Rainfall is not relevant for pumped-hydro. The same water is pumped up and down between the upper and lower reservoirs. So pumped-hydro schemes have an upper reservoir that is entirely man-made, with no natural inflows.

In the case of Tantangara-Blowering or Tantangara-Talbingo, the inflows to Tantagara will make the scheme more economic than being dependent on pumped-hydro alone. I did not include the revenue from straight hydro generation in my calculations. The additional revenue would not be great, because most of the water captured by Tantangara must be diverted to Eucumbene for storage for use when most needed and when the peak power is most valuable.

The sentence in the second paragraph of my previous post was supposed to read “Some [not “so”] pumped-hydro schemes have an upper reservoir that is entirely man-made, with no natural inflows.”

Initially I compared four options, however I had not considered the Tantangara-Talbingo option previously. I have added it this morning. You are correct, it is better on a cost per kW basis. The key parameters and the cost of the four original options plus Tantangara-Talbingo are summarised below:

Power Storage Stg rate Cost Cost per unit Pw Cost per unit energy storage capacity

MW MWh MWh/h $ $/kW $/kWh

Tantangara Blowering 8,482 526,692 5,104 $6,689,079,648 $789 $13

Eucumbene Blowering 7,729 3,320,623 4,651 $8,336,829,648 $1,079 $3

Eucumbene Talbingo 2,140 24,946 1,168 $2,229,693,216 $1,042 $89

Tumut 3 Expansion 3,000 10,867 1,762 $3,597,948,848 $1,199 $331

Tantangara Talbingo 6,903 24,946 3,865 $4,022,349,120 $583 $161

The reviewers suggested that my estimates are low by a factor of about 2. I accept the reviewers comments; they have a lifetime of experience in hydro projects and are still fully involved. One is the Chief Engineer for a major utility with enormous hydro projects and still building them. The other is chief designer for another organisation and is on site building one in Asia now. We could not get a better sanity check from more experienced people than these two have provided. We can rely on what they have said in their reviews.

Let’s consider your most important concern about the costing for TT. You suggested we could manage with two instead of three tunnels. This is not correct. Let me explain how I did the simple analysis. The aim was to get a cost comparison. So I needed some detailed cost breakdowns by major components. The best available was for Tumut 3, a pumped-hydro facility built in about 1967. The cost breakdown for each major contract is available in the public domain. The costs from about 1967 and need to be escalated by about a factor of 10 to 2009 A$.

The Tumut 3 engineering specifications are also available. To make the comparison simple, I kept the rate of water flow the same for all options (except Eucumbene Talbingo where I used only one tunnel) and increased only the hydraulic head (or pressure). I assumed the power station, turbines, generators and length of steel pipe on the surface would be the same size for all options. Of course, this is a gross simplification. They should all be scaled up in proportion to power, (but not necessarily as a simple factor).

Many improvements are needed to my original estimates. The power station would need to be build below water level in the existing Blowering dam. That will be much higher cost than I allowed for. The upstream and down stream tunnels must be portaled below water level. The intake structure must be built below water level. These will add considerable extra costs. We would need a steel lined tunnel from the downstream portal to the position where the surface is some 400m above the tunnel level for TB and some 350m above for TT. I did not fully allow for the cost of the steel liner, nor for the logistics of getting the 12m diameter pipes from Sydney to Blowering. This may require high cost modifications to the highways from Sydney to Blowering. All these extras were no included in my estimate in the article published at the top of this thread.

What about the need for 2 or three tunnels for TT? The calculations are on the basis that the total flow is the same for all options and is the same as for Tumut 3. The total flow rate is 1133 m3/s. The flow velocity must be less than 3 m/s and preferably much less. One hydro project I worked on in Canada had a 2.8 km tunnel and the velocity in the unlined rock tunnel was 1.5 m/s. So, I have used the upper end of the acceptable velocity as the basis for the tunnel cross sectional area. So three tunnels are required and they are the same diameter for all projects, 12.7m (larger would be better from a head loss and revenue perspective). The head loss in the TB tunnel is 23m and in TT is 9m. This is a valuable benefit for the TT project, but I have not calculated the implications for total revenue and return on investment.

The last point concerns the impact of adding a 7GW pumped storage facility to the performance of the Tumut 1, 2 and 3 hydro system. I do not agree with you that the consequences would be insignificant. The scheme was optimised during design to obtain the maximum output and revenue consistent with meeting the obligations to provide water as required for irrigation. Water is released from Eucumbene to Tumut Pond and released down through Tumut 1, Tumut and Tumut 3 power stations. Some is held back below Tumut 3 and pumped back up at night into Talbingo. The remainder is released to Blowering where it is held for release to suit irrigation needs. Talbingo is designed to optimise the storage capacity above Tumut 3 so the best value can be extracted from that water. It is designed to hold the water pumped up by Tumut 3 at night and also to hold the flows released through Tumut 1 and Tumut 2. If all Talbingo’s stotrage was not required, its active storage would have been designed to be less. This would have given a higher maximum head and therefore more power in Tumut 3. The engineers knew what they were doing. We cannot add 7GW pump storage to that system without a significant impact on the operation and performance of the existing system. In my calculations, I have worked on the basis that 10% of the storage in Talbingo can be considered available for use by the new pump-hydro system.

At the moment I believe the Tantangara-Blowering pumped hydro facility would cost in the order of $13 billion ($1,577/kW) Tantangara-Talbingo pumped hydro facility would cost in the order of $8 billion ($1,165/kW). However, TB can store 527 GWh but TT just 25 GWh allowing for the impacts on the existing systems.

A more detailed comparison of the options would be needed to take this any further.

One option to be considered would be underground versus surface power station. The underground power station is much more costly, but it avoids much of the steel tunnel liner. This is as far as it is worth my while to take this simple options comparison.

dashpool and other contributors to this thread,

Further to my previous comments, I suspect none of these pumped-hydro schemes are economically viable at present. They may become viable if we adopt nuclear power. I expect some of these pumped-hydro schemes may start to be developed, in stages, once about half our coal fired power stations have been replaced with nuclear. I suspect pumped hydro will not be viable until we have a lot of nuclear installed, most of the coal is replaced and we are turning to pumped hydro instead of gas for the fast-response, load-following generation capacity.

dashpool

I am interested in this comment. I haven’t done the calculations for the cost of the steel liner, but if you could I’d be very interested.

Peter said:

And on this point I strongly suspect Peter has it right. It may well be that pumped hydro turns out to be the most cost-effective way of delivering increased power at short notice.

Fact is that pumped hydro is the ONLY solution that can be currently scaled, at a reasonable cost, and with a mature technology, to store excess nuclear power for peaking.

I suggest there are perhaps three ‘water’ connections for surplus nuclear electricity

1) pumped hydro

2) reverse osmosis desalination

3) high pressure electrolysis

A desal co-located with a coastal NPP could also expend electrical energy pumping the fresh water to a large holding tank in the hills above the city. That source can be mixed with conventional water supply when required. Electrolysis can produce compressed hydrogen and oxygen as a chemical feedstock and medical good respectively. These will be more expensively than hydrogen from steam reformed natural gas and oxy enriched air produced by the PSA method. However I have no doubt the demand for hydrogen will be insatiable in a few years.

Thus a large NPP could split the load between the grid, the desal and the electrolyser. I think they should be located together as a PR exercise and to reduce suspicions that the water and hydrogen output are underpinned by coal.

Dear Peter,

Your method for estimating costs (without scaling cost of certain system components for power generation, steepness or head height), and a very low figure for tunneling costs has led you to select a very large project which has extremely long tunnels and high head.

More accurate analysis might show smaller power plants to have comparable or smaller cost/kw.

I therefore am not confident that your system selection was correct. I don’t disagree with the referee’s comments though. I think that the cost estimates were too rough to say much except that pumped hydro would not be insanely expensive, even at quite large power. I don’t have the knowledge to provide better cost estimates, unfortunately. But it is an interesting exercise.

My gut feeling is that since large hydro has already been constructed in the area, with big tunnels, pumped storage should be feasible.

On flow rates: you seem to be claiming that a particular flow velocity is appropriate, without reference to the steepness or diameter of the pipe (based on previous experience). I would suggest that since the tunnels are very expensive, you had better figure out exactly how much flow you can put through the tunnel. Longer tunnels have more drag.

Data point: Jinping-II uses 4 headrace tunnels with nominal area of 100m^2 each (excavated diameter is 12.4m, but quite a lot of lining is required due to large overburden and water). At 4.4GW rated power (some sources give 4.8GW), efficiency 0.85, and rated head 310m (minimum head is 280m), gives a flow rate of 4.3m/s.

(www.rowa-ag.ch/images/PDFs/ref_JinPinStudie_d.pdf gives 4m/s)

We seem to both agree that the TT project would not interfere significantly with tumut scheme for the proposed pumping time.

On lining, 0.2m thick A517 steel would be sufficient for 8MPa pressure tube 12.5m diameter, at 30% of yield strength. That gives ~60e3 kg/m. At steel prices of a few dollars a kilo for simple steel products, plus assembly, transport, $250,000/m should be about sufficient. Liner thickness can decrease along the tube somewhat. To avoid transporting huge tubes, I believe that the liners are cut into sections, shaped so that welds are at a large angle to the line along the pipe. I am not a structural engineer, so this estimate is to be taken with appropriate caution.

Almost all high head hydro is built in caverns nowadays.

ps: Jinping II headrace tunnels are 17.2km long.

Hi dashpool,

Thank you for these comments and suggestions. This is much appreciated. I’ll provide a brief response to each.

This started off as a ‘ball park’ estimate. It is not a detailed cost analysis of all possible projects or options. It was confined to looking at the cost of adding pumped hydro to existing reservoirs in the Snowy Mountains Scheme. The initial proposal was to increase the capacity of Tumut 3 by a factor of two or three, including pumping back from Blowering. This was the least economic of the four options initially considered (in this rough comparison)

I agree that scaling up the power station, turbines and generators for the higher power will increase the estimated cost of all the options.

The slope of the tunnels is not relevant. The system may be designed with a near horizontal low pressure tunnel, shaft and high pressure tunnel or a sloping tunnel. Those are details that would be considered in preliminary design. They do not need to be decided during the earliest stages of feasibility. Regarding the “very low figure for tunneling costs”, I am not sure if you looked at the reference I gave you. This reference presents a compilation of world wide experience in all types of tunnels and rock conditions. The Swiss rail tunnel you pointed me to is not much help, unless we can separate out the costs for just the rock excavation component for the actual tunnels, excluding the tunnel lining, rails, signals, stations, cross tunnels, ventilation and rolling stock. All those appear to be included in the US$9 billion total project cost. Do you have the actual cost for the rock tunnelling? If so, can you point me to a link?

I agree that projects with shorter tunnels would be lower cost, everything else being equal. I am not aware of any other pumped hydro project that has tunnels as long required for these schemes. But this just supports the contention that these proposed pumped hydro projects, are not viable at this stage. I suspect this exercise supports the point, made earlier in this thread, that pumped hydro is not likely to be viable until a substantial amount of coal power is replaced with nuclear.

Small pumped-hydro projects are not viable either – without large subsidies.

My gut feel is that these projects are not economic until we have a major component of nuclear in the generation mix. If these projects were viable now, they would have been investigated extensively and repeatedly by now, and built long ago. They are not even on the radar. By the way, the water tunnels on the Snowy are not large. They are small span, and excavated by drill and blast – rough surface.

Practice for unlined rock tunnels for hydro schemes is maximum flow rate of 3m/s and usually well below that. The flow velocity, surface roughness and tunnel length are factors in the calculation of the head loss. The slope of the tunnel is not. The cross sectional area of the tunnel(s) is determined from the flow rate and flow velocity. The number of tunnels is determined by the excavation cost; larger diameters cost less per m3, but larger tunnel boring machines are less readily available and the mobilisations costs can be higher (eg modification to the highways from Sydney to Blowering).

I considered four configurations for the diameter and number of tunnels:

6 tunnels of 8.0m diameter, 3.76m/s = 401m head loss; cost $3.731 billion

3 tunnels of 12.7m diameter, 3.0m/s = 69m head loss; cost $3.295 billion

3 tunnels of 13.9m diameter, 2.5m/s = 43m head loss; cost $3.570 billion

2 tunnels of 15.5m diameter 3.0m/s = 35m head loss; cost $2.827 billion

I based the costs on 3 tunnels of 12.7 m diameter, because the tunnel boring machines for the larger diameters are less available.

I understand the Jinping-II headrace tunnels are lined. Therefore, they can have a higher flow rate than the unlined rock tunnels assumed for the T-B project. If the tunnels were lined they would be far more costly.

You have misunderstood my comments on that. I said the opposite.

Regarding the thickness of the steel plate for tunnel liner, did you look at the reference I provided on the design of tunnel liners (it is linked in the article above). The static pressure during pumping is 9.75MPa, not 8MPa. Also, I wonder, did you allow for dynamic internal pressure (when there is rapid shut off), for the external pressure and the buckling failure (see reference)?

You are correct that the steel plate thickness decreases from the portal to the end of the steel liner. The rate depends on the height of the ground surface above the tunnel. Let us assume the average thickness is 200 mm. We have three tunnels of 3 km length, 9,000 m @ $250,000/m = $2,250,000,000. That is 4.5 times more than I allowed in my estimate.

An underground rather than surface power station may be the better option. The cost of the steel liners would be much less; however, the cost of the underground power station is considerably more than the cost of a surface power station. The options would be compared during feasibility investigations. As pointed out above, this started as a simple exercise to get a rough cost estimate for the projects which were being claimed to be low cost and readily available. To get rough cost estimates I had to use information readily available. 33 year old costs are available for Tumut 3, a a pump storage facility with a surface power station, and located in Australia. That is a good start. World wide experience is that pump storage projects cost around $2000/kW.

Hi Peter,

Just to be clear:

I don’t think that your are exaggerating the cost of pumped hydro. I think your costs are too inaccurate to correctly select a project, or to give that much information about final cost. Thats why you end up falling back on ‘World wide experience $2000/kW’.

1) Tunneling costs:

You agreed earlier (8 April 2010 at 21.26) that the figure (fig 24 in reference) you used did not give all the costs. Also, it is not clear whether the tunnel is in ‘good ground’ or not. I don’t think you have a very useful number at all. Hopefully the part of the snowy mountains we are tunneling through is mostly granite, but who knows. I agree that the Gotthard tunnel estimate includes other things than tunneling, and the large overburden probably makes it more expensive: I intended it as a ‘high ball’ figure. Tunneling costs may indeed be a factor of two higher than this figure, rather than ~8 times higher.

Power station costs obviously need to be scaled with power to get even vaguely indicative figures.

2) Flow rates:

The ‘slope’ I am talking about is the overall slope (rated head)/(total length of tunnel). The point you seem to be missing is for the same tunnel efficiency [(head loss due to friction)/(rated head)] for otherwise identical tunnels, the flow rate will depend on the ‘slope’.

In other words 3m/s seems to be acceptable for a tunnel from Tantangara to Blowering, but if you were building the tunnel to Brisbane, the acceptable flow rate will be lower. If your tunnel to Blowering was 212km rather than 53km long, the acceptable flow rate for the same head loss would be ~1.5m/s.

Scaling your figures for TT, 25km tunnel for same flow rate gives 32m head loss. The efficiency of the tunnels alone is 95% (32m/670m), compared to 92% (69m/827m) for TB. So your TT tunnels are excessively conservative. I am not sure why we are having so much trouble engaging here: perhaps I am not expressing myself clearly.

3) Jinping II

These tunnels are lined for stability. I don’t know what the cost of lining a tunnel bored by a TBM in order to make it smooth would be. Certainly at an average thickness of 0.1m shotcrete material costs don’t look too bad.

Reference:

‘The hydraulic roughness of unlined and shotcreted TBM-bored tunnels in

volcanic rock: In situ observations and measurements at Kárahnjúkar Iceland’ by Kristín Martha Hákonardóttir et.al in Tunnelling and Underground Space Technology 24 (2009) 706–715

Unlined TBM walls 7.6m diameter, avg. 20mm roughness. Lined shotcrete walls, 10mm roughness. 10% difference in Darcy friction factor, 5% difference in velocity. for same head loss: conclusion, no, lined tunnels not significantly better.

4) Using 10% of Talbingo gives ~4hours of power and meets the original specification of 3 hours.

5) Lining: my figures were for 670m head TT where 8MPa seems adequate. I assumed that you wanted only 1km per tunnel, as per your cost breakdown. At 3km it indeed becomes very expensive. The pumps have to be buried deeper than (maybe 50m below) minimum dam level to deal with cavitation. So your turbines have to be at ~250m in altitude. Actually at this point it is clear that you are dealing with an underground power station anyway so this discussion is moot (same goes for TT obviously).

If you are designing a connection with 3km of 9MPa liner it indicates you are doing something wrong. By the way, where are your surface pipes meant to be? It seems like your whole design needs a complete rethink.

[…] Over at BraveNewClimate, there are some plans and cost estimates for a large (9 gigawatt) pumped hydroelectric storage facility in Australia. Two reservoirs separated by 875m of elevation would be joined with a 53km pipe. The […]

Dashpool,

Thank you again. You’ve made a lot of good points. Pity we didn’t have this discussion before I got started. I did not begin the exercise envisaging that I would get into this level of detail.

Below I will reply to the points in your latest post.

I agree with this statement. But ranking the projects was not the purpose of the exercise, as I explained in previous posts. In fact, the article did not include the rough analysis of the other projects. This was something I added in answer to one of your questions. What the exercise does show is that none of the projects are economically viable given the current mix of generators in the NEM. So it is no correct to claim that these pumped hydro sites could provide low-cost energy storage for intermittent renewables. It was that claim that the paper was originally written to address.

I used the world wide experience as a sanity check. It is unreasonable to believe that Australia has a pumped-hydro option sitting undeveloped in the Snowy Mountains Scheme, which would cost well below world experiece. If there was a feasible option SMEC and other organisations would have been advocating it for ages. It clearly is not viable.

I used “average tunnel costs” from the Evert Hoek’s figure 24, http://www.rocscience.com/hoek/references/H2001b.pdf. For the 12.7m diameter tunnel this gives a cost of A$155/m3 when escalated to 2009 A$. I could equally have used “good ground requiring minimum support” as that is the likely rock conditions for this tunnel. I’ve had some experience tunnelling in the area, am familiar with the rock types along the tunnel line, and have walked and done geological mapping in the area near Tantangara Dam and Long Plain. There is considerable experience and knowledge about the tunnelling conditions in the area. I have alos reviewed the 1:250,000 geological maps of the area which are available on-line from Geoscience Australia. I have written up a short description of the geology and rock conditions in the article. Having said this, if you can suggest a source of better cost figures for TBM tunnelling in granitic type rock, I’d be grateful. The Hoek figure 24 is still being widely used for preliminary estimating (that was confirmed by two of the people mentioned in the acknowledgements who are actively involved in underground excavation design and estimating, so I would need something more credible to persuade me to move away from these figures). I do agree that there may be some missing costs, and I may not have included sufficient escalation. However, the the TBM tunneling is cheaper and this would tend to reduce my estimate. However, all this is way beyond the level of detail I had intended to get into when I did the calculations initially.

I have just looked, for the first time, at possible tunnel alignments from Tantangara to Talbingo. This alignment will be a far more costly per kilometer than the Tantangara-Blowering alignment. For most of the tunnel length, the hydraulic head will be above ground level, meaning the tunnel will have to be lined as a pressure tunnel to prevent leakage. There are deeply incised creeks, where the tunnel will surface and have to be bridged, or the tunnel will need to be excavated at a relatively steep slope at the Tantangara end and then run at depth. The tunnel will pass through the limestones near Yarrongobilly Caves, meaning it may have to deal with cavernous limestones so there is the risk of dangerous, sudden water inflows during tunnelling. Furthermore, these sections would need to be lined as a pressure tunnel. From my rough scaling, I expect the tunnel will be more than 30km long, not the 20km you estimated. There is no suitable location for surge shafts. I expect the cost of this tunnel would be considerably higher per kilometer than the Tantangara-Blowering tunnel.

I agree I do need to scale up some of these costs, as I said before. I doubt the power station costs are proportional to power. The power of Tantangara-Blowering is six times higher than Tumut 3. However, I expect the costs would be perhaps 2 to 3 times higher than Tumut 3. I should have used twelve 750 MW instead of six 1,500 MW turbines, pumps and generators. The flow rate is the same as for Tumut 3 so I am guessing the turbines and pumps need only to be scaled up for strength, not flow. The generators should have been scaled up from 250MW to 1,500MW in my original estimates.

If I re-do the calculations, I would change from 6 to 12 turbines with half the flow rate of the Tumut 3 turbines and scale up from 6 generators of 250MW to 12 generators of 750MW. To do this I would reduce the cost of turbines to say 0.75 of the Tumut 3 turbines and increase the total cost of the generators by a factor of 4.5 of the total cost of the Tumut 3 generators.

The pumps are separate from the turbines in Tumut 3, but I understand would be the one unit in the Tantangara-Blowering power station (reversible Francis turbines used for both pumping and generating). So there is a cost saving for the pumps. I had included in my original estimates the factoring up of the pumping capacity.

I would double the size of the power station to cater for the 12 x 750 MW units instead of 6 x 1500 MW units (remembering that the turbines would have half the flow and therefore be smaller than the Tumut 3 turbines).

To keep this discussion in context, we are playing with power station costs that make up about 5% of the total project cost. The cost for the power station equipment in the article above totals $342 million. Roughly, I should double to tripple this to say $700 million to $1 billion. The total project cost increases from $6.7 billion to $7.4 or $7.7 billion (based on my initial figures). I’ve already accepted the cost of the project is more likely to be around $15 billion, so these changes are not very significant in the total picture. The component of the cost estimate I have the least confidence in is the steel tunnel lining.

You are expressing yourself clearly. I now understand your point. I felt previously it was a ‘down in the weeds’ issue so I had not examined it to this level of detail. The head loss in the 12.7m diameter, 53 km unlined rock tunnels for Tantangara-Blowering, I calculate as 69m..

Today I’ve looked at three options for the Tantangara-Talbingo (TT) tunnel. I’ve used 30 km tunnel length. Option 1 has three tunnels of 12.7m diameter, head loss = 39m. Options 2 and 3 keep the head loss the same as for Tantangara-Blowering (TB), i.e. 69 m. Option 2 has 3 tunnels of 11.4m diameter. Option 3 has 2 tunnels of 12.3m diameter. Now I see what you are getting at! 🙂

Tunnel excavation cost comparison:

TB with 69m head loss (3 x 12.7m x 53km tunnels) = $3.281 billion

TT with 26m head loss (3 x 12.7m x 30km tunnels) = $1.864 billion

TT with 69m head loss (3 x 10.5m x 30km tunnels) = $1.657 billion

TT with 69m head loss (2 x 11.4m x 30km tunnels) = $1.239 billion

The two tunnel option reduces the tunnel cost for TT by about $425 million. However, as pointed out above, I expect the cost estimates for the TT tunnels are too low in comparison with the TB tunnels. I expect they may be too low by perhaps 25% because of the reduced land height along the tunnel line, the need to cross deep ravines and the need for a pressure tunnel lining along much of the tunnel length.

Now I see what you were pointing out in your previous posts. Thank you. I didn’t take this into consideration when I ran the numbers for the TT option on Monday. I recognise there will be many other items that could also be improved for the purposes of comparing the projects. I accept your point that the rough figures I’ve produced are not sufficiently refined to allow a ranking of the projects. However, although the figures are not good enough to rank the projects, I still believe the exercise confirms that the projects are not viable with the existing generation system nor for energy storage for renewable energy generation such as wind and solar power.

3) and 4), I’ll skip over. Too much effort to explain any further. We can come back to these later if we want to get down to this level of detail.

The 9.75MPa pressure I gave was for TB and is for the maximum static head plus the friction loss. The dynamic head also must be added. You seem to know a lot about this, so I would be interested in what you would suggest. TB is the project I’ve done the main calculations on. As I mentioned in my previous post, I had not considered the TT option when I did the calculations last year (despite having said so in my first reply to you. My response was from memory). Monday morning I did a quick scaling to get the TT project. I have not analysed it to the same level of detail as I did for TB. However, for TT the maximum static head plus friction loss – when pumping from minimum operating level in lower reservoir to full supply level in upper reservoir – would be 763m.

I agree an underground power station might be the preferred option, but I do not have costs I can use. Without them, I cannot do the sort of ball park analysis I set out to do. I’d also point out that neither Tumut 3 nor Wivenhoe, Australia’s two largest pumped-hydro projects, have power statons. Both have surface power stations And neither go 50 m below minimum operating level.

The length of the steel lined section of the tunnel depends on the topography at the down stream end of the tunnel. The surface above the tunnel line does not get above above the Tantangara Full Supply Level until nearly 7 km from the downstream portal (see the east-west section of tunnel at the Blowering end of the tunnel).

I agree the design could do with a rethink. And, of course, that would be done as design progressed. The design for the orginal comparison was based on Tumut 3, as I’ve mentioned above. I had looked at surface penstocks at onstage and then settled on a configuration with surface pipes the same length as at Tumut 3, same diameter, and thicker steel for the higher pressure. I agree, if a surface power station was selected the configuration used at the Wivenhoe power station would be more suitable. There are lots of things to improved. I agree with many of your points and thank you for your contributions. This discussion is helpful for non-experts (of which I am one).

Main uncertainties in the cost estimates

1. Steel liner

2. tunnelling

3. underground versus surface power station

4. turbine/pump, generator and transformer

5. access and modifications to highways

Conclusion:

After all this, it seems the total project cost of around $15 billion for TB is unchanged.

I expect Tantangara-Talbingo would cost around $10 to $11 billion and have significant constraints on the amount of energy that could be generated without compromising operations in Tumut 1, 2 and 3.

We’ve been playing at the edges of the total project costs, except for the steel liner, which has a major uncertainty on the upside.

This rough analysis shows why these pumped hydro projects are not viable with the existing generation mix, and would not be suitable for energy storage for intermittent renewable energy. They may be viable once a substantial proportion of the electricity is supplied by nuclear power.

What next?

I am thinking of improving the calculations a little. I’d probably stick with a surface power station because I don’t have access to costs for an underground power station that I could scale up. I’d scale up the turbine/pumps, generator, transformer and power station as mentioned above and add some costs for the underwater work. If I could get better costs for tunnelling than Evert Hoek’s Terzaghi Lecture, I would use them, but I am not too concerned if I stick with Hoek’s figures and inflate them some more. The caption for Evert Hoek’s Figure 24 says: “Approximate costs for tunnel excavation and support (1999 US$). These costs do not include concrete lining, tunnel fittings or tunnels driven by TBMs.” Using TBM’s will be lower cost than drill and blast, so this will tend to offset tunnelling costs not included so far.

However, it is not worth my while re-doing the calculations unless I can get some help with the calculation for the steel costs. Would you be prepared to help me with that? I can provide the figures from two projects I used as the basis for my estimate. So, if I provide those figures, could you calculate the cost for the steel tunnel lining? I will recheck the length required.

Can I just say how interesting I have found the exchanges between Dashpool and Peter Lang! This is a fabulously informative set of posts especially for those of us interested in the potential of pumped storage to cost-effectively underpin clean energy systems.

Ewen,

Thank you for that comment. I am learning lots too!. I thank dashpool for his comments and hope he will continue to post here.

I mentioned the Wivenhoe pumped hydro project, near Brisbane, in my previous post. It is another example of a pumped-hydro project with a surface power station, albeit a low head one. Here is a fact sheet on Wivenhoe

http://www.tarongenergy.com.au/Portals/0/docs/factSheets/Factsheet%20-%20Wivenhoe%20Power%20Station%2024%20June%202008.pdf

I agree, thanks to Peter and dashpool for their incredibly informative comments (and to Peter for the lead post). This is ‘open blog science’ at its absolute best.

Dear Peter,

Thankyou for the informative reply. I don’t have that much more time right now, so I won’t post in that much detail and I will skip various points.

The point about underground pumping stations is that you can’t suck water uphill very far. Water head from bottom reservoir at pump intake + Atmospheric pressure has to be greater than zero. Because Jounama pondage varies only 9m in height, the pump intake at Tumut III could be built at 393m (max dam level) and still have positive intake pressure. I think actually it is built below this (by excavating a bit) but I can’t find the numbers.

So pumps at Blowering need to be built no higher than 10m above minimum dam level, 316m above sea level (actually somewhat lower than this to account for dynamic pressures in the pump). Since the ground next to the maximum dam level is at 380m, the pumps have to be significantly underground (or you could tunnel to the north side of the dam where the ground is lower, but this seems suboptimal).

On the cost of steel liners, I’m not sure I can do a particularly good cost estimate. I am assuming ‘typical’ steel costs and that material costs are around 50% of the total. Also (conservatively) assuming that the rock supports none of the load, which is reasonable for the thick part of the liner near ground level. In liners with similar internal and external pressures in good rock, the rock can support almost all of the hoop force and the liner, which acts like an elastic waterproof membrane, should be much cheaper (this is explained in the pdf on liners that you linked to). Dynamic pressures are typically limited to around 20% of the static pressures using protection devices like surge shafts and air chambers. (e.g. Applied hydraulic transients for hydropower plants and pumping stations By Mihail Popescu et. al)

Hi dashpool,

And thank you for your great replies too. Some readers are interested in the discussion so I’ll continue; the discussion provides readers with some insight into the sort of considerations involved in designing such systems. It provides insight as to why such systems are not as cheap as they often seem at first, and it illustrates the magnitude of the unknowns involved in the estimates. So here are responses to your post of 15 April @18:06.

I agree that pumps are normally submerged, but I was surprised by your comment about them being submerged by as much as 50m. I realise that this may be the case for an underground power station that is located a long way from the downstream reservoir, as this power station would have to be. Here are the relevant figures for Tumut 3 which is a ‘surface’ power and pump station (see the photo in the lead article for the thread):

Minimum Operating Level for pumping is: R.L.382.5

The centre of the pump scroll case is: R.L.362

The bottom of the excavation for the pumps is: R.L. 351

So the lowest point of the excavation is 32m below the Minimum Operating Level.

My original estimates for the power/pump station on the Blowering reservoir assumed the same arrangement as Tumut 3 (surface power station with submerged pumps), but based on the Blowering Minimum Operating Level, which is R.L.306. So the lowest point of the excavation would be at R.L. 274.

I agree that an underground power station may be more suitable, and this would be decided as design progresses. The cost of steel tunnel liner would be much less, but the cost of an underground power station would be more than a surface power station.

The Wivenhoe power station is also interesting for comparison. The lowest point of the excavation is 2m above seal level. It is a surface power station with similar arrangement to Tumut 3, but with two pumps and turbines. (vertical section: http://www.tarongenergy.com.au/Whatwedo/Generating/WivenhoePowerStation/Howelectricityismade/tabid/150/Default.aspx

Fact sheet: http://www.tarongenergy.com.au/Portals/0/docs/factSheets/Factsheet%20-%20Wivenhoe%20Power%20Station%2024%20June%202008.pdf

Steel Tunnel Liner Cost Estimate: