Download the printable 33-page PDF (includes two appendices, on scenario assumptions and transmission cost estimates) HERE.

Download the printable 33-page PDF (includes two appendices, on scenario assumptions and transmission cost estimates) HERE.

For an Excel workbook that includes all calculations (and can be used for sensitivity analysis), click HERE.

By Peter Lang. Peter is a retired geologist and engineer with 40 years experience on a wide range of energy projects throughout the world, including managing energy R&D and providing policy advice for government and opposition. His experience includes: hydro, geothermal, nuclear, coal, oil, and gas plants and a wide range of energy end use management projects.

Summary

Here I review the paper “Simulations of Scenarios with 100% Renewable Electricity in the Australian National Electricity Market” by Elliston et al. (2011a) (henceforth EDM-2011). That paper does not analyse costs, so I have also made a crude estimate of the cost of the scenario simulated and three variants of it.

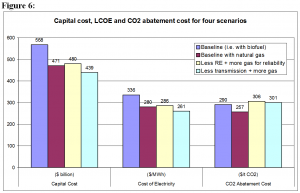

For the EDM-2011 baseline simulation, and using costs derived for the Federal Department of Resources, Energy and Tourism (DRET, 2011b), the costs are estimated to be: $568 billion capital cost, $336/MWh cost of electricity and $290/tonne CO2 abatement cost.

That is, the wholesale cost of electricity for the simulated system would be seven times more than now, with an abatement cost that is 13 times the starting price of the Australian carbon tax and 30 times the European carbon price. (This cost of electricity does not include costs for the existing electricity network).

Although it ignores costings, the EDM-2011 study is a useful contribution. It demonstrates that, even with highly optimistic assumptions, renewable energy cannot realistically provide 100% ofAustralia’s electricity generation. Their scenario does not have sufficient capacity to meet peak winter demand, has no capacity reserve and is dependent on a technology – ‘gas turbines running on biofuels’ – that exist only at small scale and at high cost.

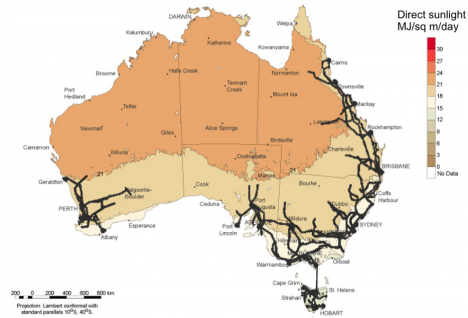

Map of Australia’s transmission lines. There are no transmissions lines to any of the proposed CSP sites, and the best solar areas are far removed from the existing transmissions infrastructure.Source: Grattan Institute, Figure 10.1 (attributed to DRET (2010), Grattan Institute)

Introduction

I have reviewed and critiqued the paper “Simulations of Scenarios with 100% Renewable Electricity in the Australian National Electricity Market” by Elliston et al. (2011a) (henceforth EDM-2011).

This paper comments on the key assumptions in the EDM-2011 study. It then goes beyond that work to estimate the cost for the baseline scenario and three variants of it and compares these four scenarios on the basis of CO2 emissions intensity, capital cost, cost of electricity and CO2 abatement cost.

Comments on the EDM-2011 study

The objective of the desktop study by EDM-2011 was to investigate whether renewable energy generation alone could meet the year 2010 electricity demand of the National Electricity Market (NEM). Costs were not considered. The study used computer simulation to match estimated energy generation by various renewable sources to the known hourly average demand in 2010. This simulation, referred to here as the “baseline simulation” proposed a system comprising:

- 15.6 GW (nameplate generation capacity) of parabolic trough concentrating solar thermal (CST) plants with 15 hours thermal storage, located at six remote sites far from the major demand centres;

- 23.2 GW of wind farms at the existingNEMwind farm locations – scaled up in capacity from 1.5 GW existing in 2010;

- 14.6 GW of roof-top solar photovoltaic (PV) inBrisbane,Sydney,Canberra,MelbourneandAdelaide;

- 7.1 GW of existing hydro and pumped hydro;

- 24 GW of gas turbines running on biofuels;

- A transmission system where “power can flow unconstrained from any generation site to any demand site” – this theoretical construct is termed a “copperplate” transmission system.

The accompanying slide presentation by Elliston et al. (2011b), particularly slides 5 to 12, provides a succinct summary of the objective, scope for their simulation study, the exclusions from the scope, the assumptions and the results.

The results of the baseline simulation show that there are six hours during the year 2010 when demand is not met, with a maximum power supply shortfall of 1.33 GW. It should be noted that the supply shortfall would be significantly greater with higher time resolutions, e.g. 5 minute data rather than the 1 hour increments used, but this limitation is not addressed by EDM-2011.

The EDM-2011 approach is more realistic than Beyond Zero Emissions (2010) “Zero Carbon Australia – Stationary Energy Plan” (critiqued by Nicholson and Lang (2010), Diesendorf (2010), Trainer (2010) and others), especially because EDM-2011’s approach, as they say, “is limited to the electricity sector in a recent year, providing a more straight forward basis for exploring this question of matching variable renewable energy sources to demand.” As the authors say, “this approach minimises the number of working assumptions”.

Despite the lack of costings, the EDM-2011 study is a useful contribution. It demonstrates that, even with highly optimistic assumptions, renewable energy cannot realistically provide 100% of our electricity generation. The baseline simulation does not have sufficient capacity to meet peak winter demand, has no capacity reserve, and is dependent on a technology – gas turbines running on biofuels – that currently exist only at small scale and at high cost.

The study is based on a number of assumptions that I argue are unacceptable:

- a system with insufficient capacity to meet the winter peak demand and no capacity reserve margin would violate Australian Energy Regulator (AER) requirements;

- the assumed capacity factors for the renewable energy generators are too high to be credible for the average plant life in a 100% renewable energy system;

- the assumptions about the way the existing hydro and pumped hydro facilities can be used are not practical;

- the assumptions about pumping and generating capacity of the pumped hydro plants are unjustified;

- the practicable capacity of gas generators running on biofuels (and the capability of the biofuel system to provide the fuel and store it until needed) has not been demonstrated and critical details are glossed over;

- the assumptions about a ‘copper-plate’ transmission system is unrealistic;

- the assumptions about reducing winter peak demand is highly optimistic and not borne out by recent experience.

These assumptions, and the cost of the system simulated are discussed in the following sections.

Comments on the technologies and assumptions

Gas turbines running on biofuels

Gas turbines running on biofuels are not a proven, commercially viable electricity generation technology at the scale required (IEA, 2007).

Although some countries, e.g. those quoted by EDM-2011, do have some electricity generated by biomass, there are a wide variety of technologies used, and very little of it is gas turbines running on biofuels. Much of it is in small plants, such as combined heat and power (CHP) fuelled by wood waste, chicken litter and other waste products. Most of it is in thermal plants, not gas turbines. IEA/OECD (2010), Table 3.7 lists four countries with some biogas capacity but this is mostly as reciprocating engine generators on waste dumps, sewage plants and the like. According to Energy in Australia 2011 (DRET, 2011a),Australia has 231 MW of biogas generating capacity.

The land area that would be required for the required biofuel production would be unacceptable (1.6 million hectares of prime agricultural land in good years (Electropaedia); far more in droughts; this represents 74% of Australia’s irrigated agricultural land and 4% of all arable land (ARNA, 2009)). The water requirements would also be unacceptable. As would the truck movements required to collect the biomass. A large commercial plant would need 100 to 200 truck movements per day and night collecting biomass from an area of 100 km radius (Simms et al., 2009)

The existing biomass electricity generation plants tend to be baseload or intermediate load plants. Some of the European biogas systems, which use a biomass feed, take around 30 days to make the biogas from the biomass feed. Such plants cannot be used for just the few days a year in winter when the CST, PV and Wind plants are unable to supply enough power to meet the demand. The biogas plants listed in IEA (2010) Projected cost of electricity generation, Table 3.7 have assumed capacity factors of 80%, 85% and 90%. These types of plants are not suited to the peaking plant role envisaged by EDM-2011.

Grattan Institute (2012) gives cost estimates for biofuel electricity generation inAustralia; however, the costs are based on a capacity factor of 70%. The report makes no mention of “gas turbines running on biofuels”. The technologies mentioned are steam plants and reciprocating engines. Following are three quotes from the report (Section 8):

For Bioenergy to provide 10% or more of Australia’s electricity needs it will have to use the large amounts of energy embodied within cereal crop residues

Even at 20 to 30 megawatts such plants require large amounts of biomass fuel to realise good capacity factors that are essential to offsetting the high upfront capital costs.

For a 30MW power plant at a 70% capacity factor the land area would be around 240,000 hectares and involve nearly 500 average sized wheat farms.

Note, these plants have to be run with capacity factors of around 70% to be economically viable. They are certainly not the sort of ‘peaker’ plants envisaged by EDM-2011.

For the gas turbines running on biofuels to work as envisaged by EDM-2011, I envisage biogas would have to be produced throughout the year and stored for use during the few days in winter at the times when the remainder of the renewable energy generators cannot provide sufficient power. The amount of biogas required per year is estimated to be 290 PJ (equivalent to 116% of natural gas consumed in electricity generation and 37% of total gas consumption in the eastern states in 2009-10). But most of this is required over just a few short periods in winter.

The cost of electricity from the biogas plants is crudely estimated to be $563/MWh based on the 13% capacity factor assumed in the simulations. Unlike natural-gas-fired gas turbines, which utilise low capital cost generators with readily available fuel, the biofuel proposal also requires capital intensive biofuel plants, year-round feedstock harvesting, and large-scale biogas storage and distribution infrastructure.

Given that the biogas option is so expensive, a cost estimate below was done for an alternative using natural gas instead of biogas. All other assumptions are unchanged.

However, even this alternative would be much more expensive than a system that uses gas throughout the year. In the baseline simulation, most of the gas generation would occur over a few short time spans each year. That requires either the gas supply lines be sized to deliver the gas volumes needed over the short periods, or the gas must be stored at site for use when needed. Either option will have a significant impact on the price of the delivered fuel and, therefore, on the cost of electricity. The baseline simulation has 24 GW of gas generation capacity supplying 28.1 TWh of electricity per year. However, EDM-2011’s Figure 3 shows that 26 GW is needed to provide a supply with no unserved energy and no unmet hours. This capacity in the EDM-2011 baseline simulation is about 4 times the capacity of the existingNEMgas generators.

We should expect the generators’ fuel costs would increase by more than a factor of four. One reason is that there is a small total consumption of gas over the year, but high usage rate for just a few short periods. The gas supply system would have to provide the infrastructure to deliver the peak capacity demanded, but it would be paid for by a small quantity of gas sold per year. So the gas price during the winter peak demand would have to be increased significantly. A second reason the gas price would increase is that there would be a much higher demand for gas in winter at the same time as the gas demand peaks for winter heating.

Hydro

EDM-2011 assumes the water could be saved through most of the year and used on the few short periods in winter when the renewable energy generators cannot meet the demand. This is not how our hydro schemes are designed to operate, nor capable of operating. Here are some reasons why they cannot be operated in this way:

- The generators would not be able to generate throughout the year to sell electricity at the time of peak demand. Therefore, their revenue would be much less over the year. So they would not be economically viable without a significant increase in the price they could charge for their electricity.

- The hydro generation is needed throughout the year to balance the power surges in the system. That is one of the most valuable functions of the hydro system and it will almost certainly be required to continue to serve that role.

- Hydro cannot be stored all year and released in a massive river flush over a few days in winter. To generate a great deal of energy over just a few days would mean large water releases which would compromise the management of storage and releases for irrigation and can cause flooding and unacceptable erosion to the river banks downstream.

- If the management of storage and irrigation releases is compromised the water would be released in winter and not available for irrigation in summer.

Hydro generation is constrained by the average water inflows and the water storage capacity to level out the fluctuation in water inflows over the long term. Snowy Hydro’s capacity factor is about 14%. Total generation by hydro in theNEMin 2009-10 was 12,522 GWh, and less in 2008-09 and 2007-08. This places an upper limit on the amount of hydro generation the simulation should generate.

It should be assumed the hydro generators will operate much as they do now.

Pumped hydro

The simulation assumes there will be no increase in the existing hydro and pumped hydro energy storage (PHES) capacity in the NEM. The existing pumped hydro plants have a maximum energy storage capacity of 20 GWh (Lang, 2010). There are also limits on the amount of energy that can be stored per hour and the time of day when pumping can occur.

The EDM-2011 simulation does not appear to limit the amount of energy that can be stored per day by the pumped hydro plants. I estimate the upper limit on the rate of storing recoverable energy with the pumped hydro plants is (MWh stored per hour):

| Tumut 3 | 394 |

| Wivenhoe | 328 |

| KangarooValley& Bendeela | 157 |

Furthermore, there is a minimum duration for which the pumps must be able to operate continuously once started (e.g. 4 hours). So days when the pumps will not be able to run continuously for the minimum duration will not be able to store energy.

There is also a limitation on the hours of the day when pumping and generating can occur. They cannot occur at the same time. Since most of the excess power that would otherwise be spilled occurs during daylight hours when the CST plants are able to generate excess energy, it would seem that, in the simulation, pumping must be reserved for daylight hours when there is excess solar generating capacity.

It is not clear from the EDM-2011 paper how the model handles the distinction between the energy generated by hydro versus pumped-hydro in the two Australian facilities that are both hydro and pumped-hydro (i.e. Tumut 3 and Kangaroo Creek & Bendeela). EDM-2011’s Figure 2 shows pumped hydro generating at 2.2 GW for 40 hours on 9 and 10 January – a total of 88 GWh. This is not possible. There is only 20 GWh of storage and the pumps can store energy at about 4.5 GWh per day. The existing system would need to pump for about 7 hours with all pumps operating to be able to generate for 5 hours at 0.9 GW. So, the maximum daily generation, on consecutive days, would be about 4.5 GWh (excluding draw down from storage).

It would seem, with EDM-2011’s assumption of pumped-hydro being dispatched first, the 20 GWh of available storage would not be recharged each day since only about 4.5 GWh could be recharged each day. In the simulation, pumped hydro contributes little during the critical winter days shown in Slide 12 (Elliston et al, 2011b) and generates nothing on some days, e.g. July 1, 2, 5 and 6.

Only Wivenhoe is a ‘pure’ pumped hydro facility. The other two facilities are mostly hydro, with a small pumped hydro capacity. Therefore, it is more realistic for the EDM-2011 simulation to assume the hydro capacity is 6.6 GW and the pumped hydro can generate about 4.5 GWh per day at up to 0.9 GW on consecutive days (more for a short time if drawing down from 20 GWh of stored energy).

Concentrating Solar Thermal (Parabolic Trough)

EDM-2011 assumes a 60% capacity factor for CST. The details underpinning this are sparse, thus a number of questions arise. Is the assumed capacity factor a realistic average for the life of the plant? What is the basis for the assumed capacity factor for CST? Does it take into account:

- The system performance and reliability that is likely to be achieved over the full book life of the facilities?

- Spilled energy?

- Scheduled and unscheduled outages?

- Outages in the long transmission lines (which are mostly in remote areas far from the major service centres, so repairs will take longer than for the existing system)? Inevitably, these transmission lines will have lower reliability than theNEMaverage. Therefore, the capacity factor of the wind and CST plants would be reduced because of transmission line outages.

PV

What would be the average capacity factor for a fleet of 14.6 GW of roof-top, fixed plate PV over a 30 year life?

- How much would have to be spilled because the distribution system cannot handle the peak power output and power surges?

- How much would the assumed 16% capacity factor be reduced over the 30 year assumed life of each installation as a result of, for example:

- Performance deterioration of the solar panels

- Performance deterioration due to collecting dirt and lack of cleaning

- Some PV installations stop working or are disconnected, for whatever reason, and are never fixed or reconnected

- Buildings are sold, new owners are not interested in maintaining the system; some don’t keep it connected

- Buildings are knocked down and rebuilt without reinstalling the original PV system (the cost analysis assumes an average 30 year life for the original installations).

Is 14.6 GW of roof top solar PV realistic? That would be the equivalent of 1 kW for every man woman and child, or average of over 2 kW per dwelling. The PV is assumed to be on residential dwellings many of which could be on apartment blocks with limited roof space. Many of the houses may have tree shading and many will not have sufficient north facing roof space for a 2 kW system.

While the inclusion of 14.6 GW of rooftop solar may be theoretically possible, theNEMcould not accommodate such a concentrated non-dispatchable and variable energy supply without large-scale distributed storage and advanced ‘smart-grid’ management. All of which is expensive, but no attempt has been made to cost this

Wind

The assumed capacity factor of 30% for wind seems too high for a 100% renewable system. Although this is a valid figure for individual wind farms, much of the wind energy from a large-scale network of farms would have to be spilled. So the system wide average capacity factor for wind would be less than 30% in an all renewable energy system comprising primarily solar and wind generation.

Transmission

The EDM-2011 simulation assumes a ‘copper-plate’ transmission and distribution system (“power can flow unconstrained from any generation site to any demand site”). To achieve this assumption would require extensive additions to the existing transmission and distribution systems. The additions would need to have the capacity to carry the full peak power output from each generator plant.

The distribution systems would have to be upgraded to carry the peak power output of the PV systems in each area, or have smart grids to curtail the power output of the PV systems when they exceed the capacity of the distribution and transmission systems.

The additions to the transmission system would incur additional energy losses. Therefore, the 204.4 TWh of electricity generated in 2010 must be increased to account for the extra transmission and distribution losses. Appendix 2 contains more about the ‘copperplate’ transmission system assumptions, options and the basis for the cost estimates.

Winter peak demand reductions

EDM-2011 suggest methods to reduce the peak demand in winter so the renewable energy system can meet the demand. However, this approach is inconsistent with the stated objective which is to find a 100% renewable energy solution that can meet the 2010NEMdemand.

The relationship between energy efficiency and peak load is complex. As such, caution needs to be exercised in assuming that energy efficiency measures will invariably lead to commensurate reductions in peak demand. Indeed, electric vehicles and other unforeseeable new sources of demand may increase the peak.

Scenarios costed and compared

I have made a crude estimate of the capital cost, the Levelised Cost of Electricity (LCOE) and the CO2 Abatement Cost for the EDM-2011 baseline simulation. I have included an estimated cost for needed additions to the transmission and distribution systems to allow them to approach the ‘copper-plate’ assumption.

I have also analysed three additional scenarios with changes to some of the baseline assumptions. The changed assumptions include: sufficient generating capacity to meet all demand and maintain about 20% capacity reserve (which is less than a typical level for modern electricity networks, and much less than in theNEM); natural gas instead of biogas; reduced system-wide capacity factors for CST, PV and Wind, and less capacity for additions to the transmission system. The reduced capacity factors of CST, PV and Wind are compensated for by increasing the amount of generation by natural gas. Also included is additional generation to compensate for the increased energy loss in the additions to the transmission system.

The scenarios (detailed in Appendix 1) compared are:

- Baseline EDM-2011 simulation (i.e. gas turbines running on biofuels)

- Baseline with gas turbines running on natural gas

- Less renewable energy + more gas to improve reliability – Scenario 2 with most pumped hydro capacity reassigned to hydro, reduced pumped hydro capacity factor, reduced capacity factor of CST, Wind and PV, increased natural gas capacity and capacity factor.

- Reduced transmission capacity + more gas – Scenario 3 with half transmission capacity from wind farms, half transmission capacity of interstate interconnectors and reduced capacity factor of CST, PV, Wind and pumped hydro generation because of transmission constraints.

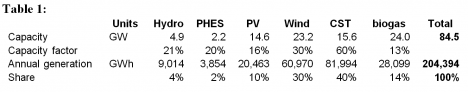

Capacity, capacity factor and generation assumptions

This section summarises the capacity, capacity factor, amount of generation contributed by each technology and each technology’s share of the total generation. These data are presented for the baseline (Scenario 1) and the three varied scenarios identified above as Scenarios 2, 3 and 4.

1. Baseline (i.e. gas turbines running on biofuels)

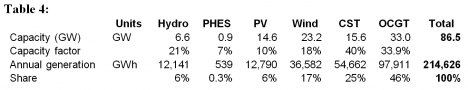

Table 1 lists the capacity, capacity factor, annual generation and share of total generation for each technology in the baseline scenario.

The capacity factors for hydro and pumped hydro energy storage (PHES) are not explicitly stated in the EDM-2011 paper. I have estimated the capacity factors for the baseline case by subtracting the energy generated by the other technologies from the total 2010NEMdemand (stated by EDM-2011 to be 204.4 TWh).

2. Baseline with gas turbines running on natural gas

Scenario 2 is the same as Scenario 1 but with the gas turbines running on natural gas instead of on biofuels. Table 2 would be the same as Table 1 except the ‘biogas’ column would be renamed ‘natural gas’.

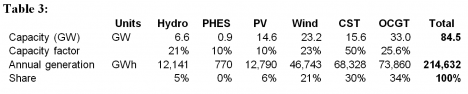

3. Less renewable energy + more gas to improve reliability

The capacity, capacity factor, annual generation, and share for Scenario 3 are:

The total capacity is not the sum of the individual capacities because all but 0.5 GW of the PHES capacity is included in ‘Hydro’. The total generation is increased from 204.400 GWh to 214,600 GWh for an assumed 5% energy losses in the additions to the transmission system. The capacity of OCGT is increased from 24 to 33 GW to ensure 20% capacity reserve above peak winter demand. From Slide 12 (Elliston et al, 2011b), on July 1 peak demand is about 32.5 GW. At the time of peak demand there is little wind, no solar and no pumped hydro generation (because the pumped hydro was not recharged during the day). So, all the generation must be provided by hydro and gas. To maintain 20% reserve capacity (in case of unavailable generators) we need about 39.6 GW of gas and hydro capacity. We have 6.6 GW of hydro capacity, (excluding the 0.5 GW of ‘pure’ pumped hydro capacity because it may not have been recharged as was the case on July 1, 2, 5 and 6). So we need about 33 GW of gas capacity to give a 20% capacity reserve on1 July 2010.

4. Reduced transmission capacity + more gas

The capacity, capacity factor, generation and share for Option 4 are:

In this option the capacity of the transmission line from the wind farms is arbitrarily halved. The capacity factor and generation for wind is reduced because the transmissions line capacity is reduced. The capacity factor and generation for CST is reduced because the capacity of the intestate interconnector lines is halved, so less power can be transmitted from the solar plants, at times. The capacity factor and generation of PHES is reduced because the reduced capacity of the interstate interconnectors will reduce the amount of excess power that can be transmitted to and stored in the PHES facilities. The capacity factor and generation of OCGT is increased to compensate for the reduction in contribution from Wind and CST.

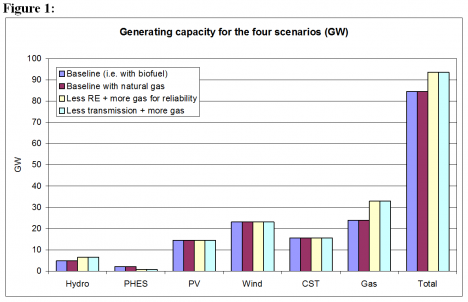

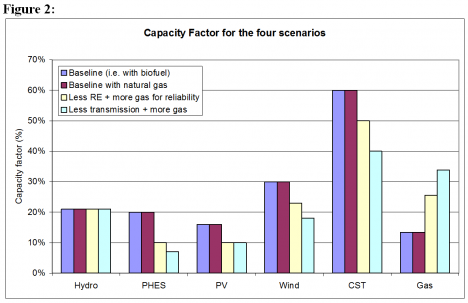

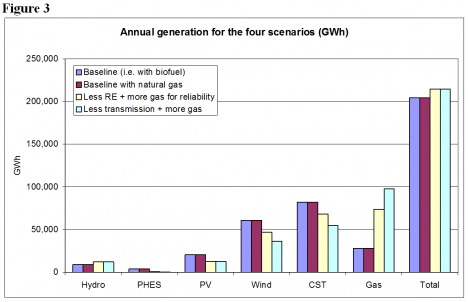

To clarify the differences between these assumptions for the four scenarios, the capacity of the technologies is compared in Figure 1, the capacity factor in Figure 2 and the annual generation in Figure 3.

Transmission and Distribution assumptions

For estimating the cost of the transmission system additions needed to achieve the ‘copper-plate’ assumption (Scenarios 1, 2 and 3), I assumed the transmission lines from each CST plant and wind farm will be sized to carry the rated power output of each facility. The transmission lines are assumed to run from the plant to the closest capital city or to the nearest entry point to the interstate interconnector lines.

The capital cities would have to be linked with interconnector transmission lines. For this crude cost estimating exercise I assumed their capacity must be sufficient to transmit the lesser of the peak demand at the receiver end or generation capacity minus demand at the sender end.

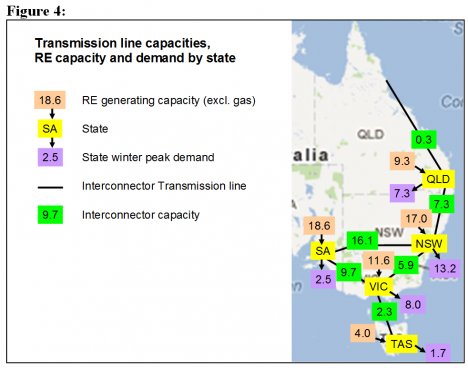

Figure 4 provides a graphic summary of the estimated capacities for the interstate transmission lines, as well as the renewable energy generating capacity (excluding biofuelled gas turbines) and the winter peak demand for each state.

For Scenario 4, the capacity of the transmission lines from the wind farms is half the rated capacity of the wind farms. The capacity of the interstate interconnectors is half the capacity assumed for the ‘Copper-plate’ scenario (shown in Figure 4). The capacity factor of the PV, CST and wind farms is reduced because of the transmission capacity constraint. Increased generation from gas compensates for the reduced generation from the CST and Wind generators.

The distribution system must allow the 14.6 GW of roof top solar PV, which is located in the residential areas, to supply their peak output without curtailment. It is assumed the transmission network would need to be ungraded to achieve this.

CO2 emissions intensity

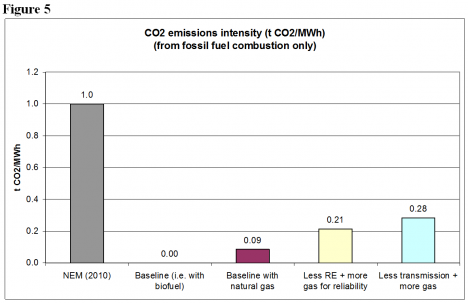

Figure 5 compares the CO2 emissions intensity of the four scenarios with the 2010 NEMemissions intensity (DCCEE, 2010). The emissions intensities for the scenarios are for fossil fuel combustion only. Importantly, they are for gas turbines running on natural gas and operating at optimum efficiency. They do not take into account the higher emissions produced when the gas turbines are operating at less than optimum efficiency, for example during start up, shut down, spinning reserve, part load and when their power is cycling up and down to respond to changes in demand and changes in the output of the PV panels and wind farms. If these were included the emissions intensity for the three scenarios that use natural gas would be higher. They would also be higher if fugitive emissions were included. The emissions intensity figure for the NEMincludes fugitive emissions. None of the emissions intensities are life-cycle emissions so they do not include the emissions embodied in the plants. The emissions intensity used for the calculations is 0.622 t CO2/MWh ‘sent out’ (EPRI, 2010). See Appendix 1 for basis of estimates of CO2 emissions intensity.

Cost estimating methodology and assumptions

This section explains how the capital cost, Levelised Cost of Electricity (LCOE) and CO2 abatement cost for each scenario was estimated.

Except where otherwise stated, unit costs are derived from the Department of Resources Energy and Tourism (DRET, 2011b).

All costs are in 2009-10 Australian dollars.

Capital costs are ‘Total Plant Cost’ and do not include ‘Owner’s Costs’ and ‘Interest During Construction’ (IDC).

The inputs and intermediate calculation steps for each scenario are presented in Appendix 1.

Capital cost

Generation

The capital cost for each generator technology is the capacity times the unit cost ($/kW) for that technology. The capacity of each generator technology for each scenario is in Tables 1, 3 and 4. The unit cost for each technology, except gas turbines running on biofuels, CST and hydro, is the average of the high and low ‘Total Plant Cost’ in the DRET (2011c, 2011d) spreadsheets, converted to “sent out”. The central estimates are also presented in ACIL-Tasman (2010). The costs in the DRET spreadsheet are ‘$/kW installed’, so they must be converted to ‘$/kW sent out’:

$/kW ‘sent out’ = $/kW ‘gross’ / (100% – ‘Auxiliary Load %’)

DRET unit costs for CST are for 6 hours thermal storage. The EDM-2011 simulations assume 15 hours storage. The capital cost for CST is factored up by 1.53 to account for the increase of solar field and thermal storage size to increase energy storage from 6 hours to 15 hours. The factor of 1.53 was derived from the DRET (2011c) costs for CST without storage and CST with 6 hours storage, assuming a linear upscaling.

The DRET costs for PV are for 5 MW commercial installations. However, the simulations assume residential, roof-top, solar PV panels. These would normally be around 1 to 6 kW (say average 2 kW), not the 5 MW to which the DRET cost figures apply. The capital cost for PV should possibly be factored up by about 1.5 or 2. I have not done this in these analyses.

The DRET spreadsheets do not include ‘gas turbines running on biofuels’. There is very little commercial experience or cost information available for this technology. The capital cost and LCOE for gas turbines running on biofuels are based on $5,051/kW. This was derived from (IEA, 2007), IEA (2010), Grattan Institute (2012) and considerations of what would be needed to provide a secure supply of biofuels inAustralia. The cost estimate for gas generators running on biofuels has high uncertainty.

There is no capital cost for the hydro and pumped hydro plants because they already exist and there are no plans in the EDM-2011 baseline or the additional scenarios to build additional hydro plants.

Transmission additions and distribution enhancements

The capital cost estimate for the transmission system additions is the product of the transmission line length, the transmission line capacity and the unit cost ($/MW.km). The unit cost for additional transmission lines is estimated at $1,500/MW.km. This is derived from the AEMO (2011) cost estimates for the South Australian Interconnector feasibility study assuming a mix of AC andHVDC transmissions lines. The cost estimate assumptions and intermediate computation results are presented in Appendix 2. The largest uncertainty is in the transmission line capacity for the interstate connectors.

The capital cost for the distribution system enhancements to carry the PV generation is estimated at 20% of the asset value of theNEMdistribution system.

Cost of electricity

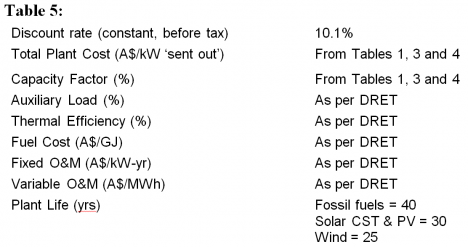

The Levelised Cost of Electricity (LCOE) for the generator technologies was calculated using the NREL LCOE calculator. The capital cost and capacity factor for each technology and each scenario are in Tables 1, 3 and 4. The other input values are as per DRET (2011c, 2011d) spreadsheets for all except the gas turbines running on biofuels, hydro and pumped hydro. Table 5 lists the other inputs.

The estimates of LCOE for generation using gas turbines running on biofuel assumes capital costs of $5051/kW (‘sent out’) and fuel price of $10/GJ to account for the costs involved with production, storage and transport. All other inputs for calculating LCOE are the same as for natural gas fuelled OCGT.

The assumed LCOE for hydro is $50/MWh and for PHES is $300/MWh[1].

The LCOE for the additions to the transmission network were calculated using the NREL calculator. The inputs are the capital cost (estimated as described above and shown in Figure 7) and the O&M costs. The O&M costs were estimated from the 2010 NEMO&M cost for transmission factored in proportion of the line length of the new additions compared with the total length of existing NEMtransmission lines (AER, 2011). Book life was assumed to be 40 years and discount rate as per Table 5.

The LCOE for the enhancements to the distribution system assumed the capital cost to be the equivalent to 20% of the 2010 value of the NEM’s distribution system assets. The O&M costs are assumed to be 20% of the NEM’s 2010 O&M costs (AER, 2011).

Costs not included in the cost estimates are:owner’s costs and interest during construction

- biofuel generating costs may be understated

- higher costs for natural gas to include the cost of building larger capacity gas pipes to supply 24 to 33 GW of peak gas generation (depending on the scenario), but with only 13% capacity factor to pay for the pipes (this means higher gas prices would have to be charged to pay for the high volume gas pipe system but with gas sales much less than the pipes could deliver).

- Increased O&M costs for CST with 15 h storage instead of the 6 h for which the DRET O&M costs apply.

- Costs for solar PV are probably too low (for kW sized, roof top, solar PV).

- Cost of electricity for the existing NEM transmission and distribution network. (Only the cost of the transmission additions and distribution enhancements are included. If the LCOE for the existingNEM network was included it would increase the cost of electricity for all options and make no change to the capital cost or CO2 abatement cost.)

CO2 abatement cost

The CO2 abatement cost is the cost to reduce emissions intensity from the CO2 emissions intensity in theNEMin 2010 to the emissions intensity that would exist with the new scenario implemented; it is expressed as ‘cost per tonne CO2 abated’ ($/t CO2).

CO2 abatement cost = (LCOE2 – LCOE1) / (EI1 – EI2)

Where:

LCOE1 = LCOE for theNEM in 2010

LCOE2 = LCOE for the scenario

EI1 = Emissions intensity for theNEM in 2010

EI2 = Emissions intensity for the scenario

The LCOE and CO2 emissions intensity for theNEMin 2010 are taken as:

LCOE1 = $45.40/MWh (AER, 2011; Chapter 1, Table 1.4)

EI1 = 1.0 tonne/MWh (DCCEE, 2010, Table 5, weighted average forNEM)

The LCOE and CO2 emissions intensity for each scenario are in Appendix 1 (and charted in Figure 5 and Figure 6).

The inputs and intermediate calculation results for the CO2 abatement cost estimates are in Appendix 1.

Uncertainties in cost estimates

The greatest uncertainties in the cost estimates are in:

- the fuel costs, capital costs and O&M costs for the gas turbines running on biofuels,

- the cost of the solar thermal plants with 15 hours of thermal storage and their lifetime average capacity factor, and

- the amount of additional transmission and distribution capacity needed.

Results

Capital cost, LCOE and CO2 abatement cost of the scenarios

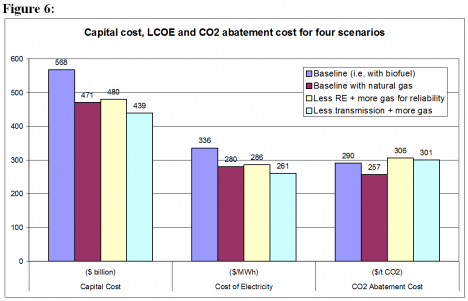

Figure 6 compares the four scenarios on the basis of capital cost, cost of electricity and CO2 abatement cost.

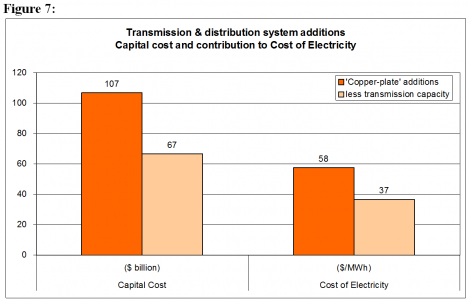

Figure 7 compares the capital cost and cost of electricity for the ‘copper-plate’ additions to the transmission system (Scenarios 1, 2 and 3) and the scenario with reduced additions to the transmission system (Scenario 4).

Discussion

General

The EDM-2011 study reveals a great deal about the difficulty and cost of a largely renewable energy electricity system forAustralia’sNEM.

The study is more realistic than Beyond Zero Emissions’ “Zero Carbon Australia – Stationary Energy Plan” (critiqued by Nicholson and Lang, 2010; Diesendorf, 2010; Trainer, 2010; and others), especially because their approach, as they say, “is limited to the electricity sector in a recent year, providing a more straight forward basis for exploring this question of matching variable renewable energy sources to demand.” As the authors say, “this approach minimises the number of working assumptions”.

Despite the lack of cost estimates – a deficiency rectified in this paper – the EDM-2011 study is a useful contribution. It demonstrates clearly that, even with highly optimistic assumptions, renewable energy cannot realistically provide 100% of our electricity generation with currently available technology. The baseline scenario does not have sufficient capacity to meet peak winter demand, has no capacity reserve and is dependent on a technology – gas turbines running on biofuels – that exist only at small scale and at high cost. Furthermore,Australia’s hydro and pumped hydro facilities cannot be used in the way assumed in the simulations.

Reliability of supply

The system simulated by EDM-2011 would not provide a reliable electricity supply. The gas turbines running on biofuels and hydro-electricity provide nearly all the power, outside sun hours, on some winter days, e.g. July 1 to 6 for 2010 (Elliston et al., 2011b, Slide 12). However, the gas turbines running on biofuels system does not currently exist at commercial scale. Furthermore,Australia’s total hydro capacity cannot be run at full power for days and weeks at a time as is assumed in the simulation. As such, without the assumed generation from these two technologies, the system simulated has near zero generating capacity for many hours in winter. This would mean load shedding or rolling blackouts across theNEM, with no electricity for most consumers during those times.

If we substitute natural gas for biofuel for the gas turbines, we’d need capacity about equal to the winter peak demand (33 GW) to provide a reliable electricity supply with about 20% capacity reserve. That means, nearly all the generation would be by natural gas on some days in winter. The plants would be ‘peaker’ plants, not ‘baseload’, so they would be open cycle gas turbines (OCGT), which are the inefficient, high cost of electricity, high CO2 emissions type of gas technology.

Cost

For the baseline scenario (Scenario 1) the electricity supply would be unreliable and the costs for a system built in the current decade are estimated to be around $568 billion capital cost, $336/MWh cost of electricity and $290/tonne CO2 abatement cost (Figure 6).

That is, the wholesale cost of electricity for the simulated system would be seven times more than with the existing system, with an abatement cost that is 13 times the starting price of the Australian carbon tax (Energetix. 2011) and 30 times the European carbon price (European Energy Exchange, 2012). (The cost of electricity does not include the costs for the existing electricity grid).

For Scenario 2 (natural gas substituted for biofuel in the baseline scenario) the cost of electricity is estimated at $280/MWh (Figure 6), which is about six times the 2009-10 average cost of electricity generation in theNEM. The power supply would still be unreliable, but less so than with gas turbines running on biofuels.

For Scenario 3, where the assumptions are changed to provide a more reliable, mostly renewable electricity supply (although still not as reliable as we have now), more gas would be used and the cost of electricity is estimated at $286/MWh. CO2 abatement cost is estimated at $306/MWh (Figure 6).

Scenario 4 – If the transmission capacity is reduced the capital cost and cost of electricity are further reduced (Figure 6) but more gas is used and more CO2 emitted (Figure 5). This scenario has the lowest capital cost and lowest cost of electricity.

The assumed ‘copper-plate’ transmission system (Scenarios 1 to 3) adds $107 billion to the capital cost and $58/MWh to the LCOE (Figure 7). The reduced additions to the transmission system (Scenario 4) adds $67 billion to the capital cost and $37/MWh to the cost of electricity (see Figure 7). These costs are included in the capital costs, cost of electricity and CO2 abatements costs.

The transmission system additions are a high cost, especially when we consider there is no increase in demand driving these extra costs. These costly transmission upgrades are only required if the policy objective is to implement renewable energy, rather than to provide low emissions electricity at least cost..

Baseload

EDM-2011 conclude “Achieving 100% renewable electricity also entails a radical 21st century re-conception of an electricity supply-demand system.” They make their point succinctly in the last slide in their slide presentation where they state “Baseload plant is an outmoded concept” (Elliston et al. (2011b).

However, since the cost of electricity from the renewable energy option is some seven times the current cost of electricity, their study does not refute the fact that the “baseload plant” is still by far the least cost way to supply most of our electricity needs, and is far from being an “outmoded concept”.

The least cost way to meet the demand and reliability requirements is with a mix of generators that are located close to the demand centres, connected by relatively short transmission lines to the main demand centres and capable of supplying the power to meet baseload at all times, intermediate load during day time on week days and peak demand whenever it occurs.

The least cost option to match generation to the demand profile in most countries where large hydro capacity is not available such as inAustralia, is usually with coal, gas or nuclear for baseload, gas and hydro for intermediate load, and gas and hydro for peak load.

Bayless (2010) in “The case for baseload” provides “an engineer’s perspective on why not just any generation source will do when it comes to the system’s capacity, stability and control”. He says:

The electric system is more than just the delivery of energy—it is the provision of reliability. First, the system must have capacity, that is, the capability to furnish energy instantaneously when needed. The system also must have frequency control, retain stability, remain running under varied conditions, and have access to voltage control. Each of those essential services for reliability must come from a component on the system. Those components are not free, and they don’t just happen. They are the result of careful planning, engineering, good operating procedures, and infrastructure investment specifically targeting these items.

The simple cost analysis presented here demonstrates that the renewable electricity system simulated by EDM-2011 cannot meet these requirements at anywhere near the cost of a conventional system.

Conclusions

I have reviewed and critiqued “Simulations of Scenarios with 100% Renewable Electricity in the Australian National Electricity Market” by Elliston et al. (2011a). That paper does not analyse costs, so I have also made a crude estimate of the cost of the scenario simulated and three variants of it. I conclude:

The costs for the simulated 100% renewable electricity system are estimated to be $568 billion capital cost, $336/MWh cost of electricity and $290/tonne CO2 abatement cost. That is, electricity would cost seven times more than now, and CO2 abatement cost would exceed current carbon prices by 13 times the starting price for the Australian carbon tax and 30 times the European carbon price (at time of writing).

The electricity supply would be unreliable.

Any largely renewable electricity system for theNEMwould be high cost, as demonstrated here. The changes made to the assumptions make little difference to the estimated capital cost, cost of electricity and CO2 abatement cost.

Recommendations

I recommended the simulation be rerun with the following changes:

- Use natural gas instead of biofuel

- Increase the gas generation capacity so there is sufficient capacity in the system to meet all peak demand and ensure 20% capacity reserve.

- Check that the system can meet demand at the 5 minute time scale, not just the average demand over 1 hour.

- Introduce constraints on hydro generation, pumped hydro energy storage rate, times of day for pumping and for generating and minimum number of continuous hours of pumping that match the actual constraints on the actual plants in theNEM.

- Reduce the capacity of transmission lines from the wind farms to a percentage of their rated power output and reduce the maximum output of the wind farms accordingly; optimise (roughly) the transmission line capacity and generating capacity to achieve the least overall cost of electricity from the system.

- Limit the peak output of the PV generators at a percentage of their peak power output to fit within the constraints of the distribution system; optimise (roughly) to achieve the least overall cost of electricity from the system.

- Limit the capacity of the interstate transmission interconnectors (this would reduce the output of the renewable energy generators at some times and reduce the pumped hydro storage rate).

- Do a loss of load probability (LOLP) analysis to check that the system being simulated meets the Australian Energy Regulator’s reliability requirements.

- Do a simulation with a nuclear power scenario to provide an objective comparison of the cost for an alternative way to provide a low-emission electricity supply.

Estimate the costs of all scenarios and compare them on the basis of:

- CO2 emissions intensity

- capital cost

- cost of electricity

- CO2 abatement cost

Acknowledgements

I would like to thank Professor Barry Brook, Dr. Jani-Petri Martikainen DrJohn Morgan, DrIan Nalder, Martin Nicholson, Graham Palmer, Dr. Gene Preston, Dr. Ted Trainer and two others in the electricity industry whom I cannot name, for their input and assistance with this analysis and reviewing this document.

References

ACIL-Tasman (2010), Preparation of energy market modelling data for the Energy White Paper

http://www.aemo.com.au/planning/0400-0019.pdf

AEMO (2011), South Australian Interconnector Feasibility Study

AER(2011), State of the Energy Market 2011

http://www.accc.gov.au/content/index.phtml/itemId/1021485

Australian Natural Resources Atlas, Land Use – Australia

http://www.anra.gov.au/topics/land/landuse/index.html#lands

Bayless, B. (2010) The case for baseload

Beyond Zero Emissions (2010), Zero Carbon Australia – Stationary Energy Plan

http://media.beyondzeroemissions.org/ZCA2020_Stationary_Energy_Report_v1.pdf

DCCEE (2010), National greenhouse accounts (NGA) factors, Table 5

Diesendorf, M. (2010), Ambitious target does not measure up.

http://www.ecosmagazine.com/paper/EC10024.htm

DRET (2011a), Energy in Australia – 2011

http://www.ret.gov.au/energy/Documents/facts-stats-pubs/Energy-in-Australia-2011.pdf

DRET (2011b), Fact Sheet – Australian Electricity Generation Technology Costs – Reference Case

http://www.ret.gov.au/energy/facts/Pages/EnergyFacts.aspx

DRET (2011c), Data – Renewable Performance and Cost Summary 2011

DRET (2011d), Data – Fossil Fuel Plant Performance and Cost Summary 2011

Electropaedia, Electricity Generation with Biofuels

http://www.mpoweruk.com/biofuels.htm

Elliston, B., Diesendorf, M. and MacGill, I.(2011a), Simulations of Scenarios with 100% Renewable Electricity in the Australian National Electricity Market

http://www.ies.unsw.edu.au/docs/Solar2011-100percent.pdf

Elliston, B., Diesendorf, M. and MacGill, I.(2011b), Simulations of Scenarios with 100% Renewable Electricity in the Australian National Electricity Market. (Slide presentation)

http://www.ceem.unsw.edu.au/content/userDocs/Solar2011-slides.pdf

Energetics (2011), Carbon price impact on energy prices

http://www.energetics.com.au/newsroom/energy_newsletter/carbon-price-announcement

EPRI (2010), Australian electricity generation technology costs – Reference case 2010

http://www.ret.gov.au/energy/Documents/AEGTC%202010.pdf

European Energy Exchange (EEX) (2012), European Emission Allowances

Grattan Institute (2012), No easy choices: which way to Australia’s energy future? Technology Analysis

http://www.grattan.edu.au/publications/125_energy__no_easy_choices_detail.pdf

IEA (2007), IEA Energy Technology Essentials – Biomass for Power Generation and CHP

http://www.iea.org/techno/essentials3.pdf

IEA/OECD (2010), Projected costs of generating electricity

http://www.mit.edu/~jparsons/current%20downloads/Projected%20Costs%20of%20Electricity.pdf

Lang, P. (2010), Australia‘s pumped hydro energy storage capacity, Oz Energy Analysis

http://www.oz-energy-analysis.org/feed/show_me.php?comm=OzEA_DG0002

Nicholson, M. and Lang, P. (2010), Zero Carbon Emissions – Stationary Energy Plan – Critique

http://bravenewclimate.com/2010/08/12/zca2020-critique/

NREL (2011), Levelised Cost of Energy Calculator

http://www.nrel.gov/analysis/tech_lcoe.html

Simms, R. et al (2009) “IEA’s report on 1st to 2nd Generation Biofuel Technologies”

Trainer, F. (2010) Another ZCA 2020 Critique

http://bravenewclimate.com/2010/09/09/trainer-zca-2020-critique/

[1] Crude estimate of LCOE: PHES plant would buy renewable energy when it would otherwise be spilled and would have to sell at about 4 times the buy price for PHES to be economically viable. If we assume electricity is bought at average $75/MWh, then LCOE for generation from PHES would be 4 x $75/MWh = $300/MWh.

Filed under: Emissions, Policy, Renewables

.png)

Excellent analysis Peter.

GT’s are indeed highly flexible Brayton tech. They can run on anything liquid or gaseous. Most can be configured to run on both when either is available. They run them on crude oil in Saudi Arabia in fact. The problem is the creation of such vast amounts of biofuel to run them on. The infrastructure for such a project is only imaginable without the costs included, IMO.

Secondly, ‘storage’. There is always a few half-truths invovled with this.

Obviously a CSP plant that has 24 hour out put can only do so at about 1/6 the name plate capacity. The ability to hold usuable heat say, 8 hours after the sun goes down is quite limited and, questionable as to reliability. Additionally, it is also weather dependent. But more importantly…these massively expensive proposals are limited to just that: ONE SET OF 24 hours of declining energy reservoirs. What happens if there is a regional, say, 1 day overcast? What then? Suppose the morning fog, something we get in California or a winter storm blocks out the sun…what kind of reliability then exists for such a scenario? It is a very one.

Very informative post. Thank you. I would just add few remarks on the biofuels:

1)Low energy density which is inconsistent with required labour productivity in developed countries: I recently read a book “The biofuel delusion”, by Giampietro and Mayumi which discussed this quite well. If we have a society where kids go to school, older people retire etc . etc, then labour metabolic rate MJ/ working hour must be very high in the productive sector. These rates are powered by the energy sector where the rate must be higher still (20000-40000MJ/hour apparently in the developed world). With biofuels it will be very hard to achieve the required metabolic rates. They had a clear example on whether crop residues are suitable feed for livestock. Answer: In undeveloped world they could be, but in developed world to break even economically you need so much higher labour productivity that concentrate feed is required.

2) Many biofuel schemes are questionable from climate perspective. When fossil inputs to agriculture and the effects of land uses changes are taken into account they essentially amount to repackaging of a barrel of oil into barrel of biofuel.

3) When mankind already appropriates maybe around 30% of continental primary production and this is the main driver of extinctions, burning some more living things into energy seems crazy. It just adds to the pressure.

4) Removing crop residues should not be assumed harmless. As far as I understand, one of the reasons why African soils are so depleted is their need to use of crop residues as energy.

Great work PL . I totally concur with the above comments. And Jani, it is indeed critical in an advanced society to have available : abundant ,affordable and clean energy , 24/7. I love the labour metabolic rate you mention, it actually is good shorthand for why certain societies have higher incomes than others. Actually I would argue that a high metabolic rate is a prerequisite, if not a sine qua non, for any society to function well in the modern world.Of course nuclear is the only way to go here, as explained so well in the above post. Finally , I would like to mention again the likely objection solar concentrating plants would get from the indigenous peoples whose land it actually is where they would be built upon.

David Walters, Jani Jani-Petri Martikainen and unclepete, thank you for the informative comments. I know little about biofuel so all the contributions we can get about this will be great.

My focus, of course, is on the cost of the system.

I’d like to get a better understanding of how a biofuels electricity generation system could work as a ‘peaker’ plants that operate at just 13% capacity factor and run only for a few short periods in winter time, as illustrated by Slide 12 here: http://www.ceem.unsw.edu.au/content/userDocs/Solar2011-slides.pdf

By system I mean all the components of the biofuel production, transport, storage, distribution for biogas or for liquid fuels. How much land area would be required at worst case (in droughts), If we need irrigated land, then how much water would be required, How would the biofuels be collected and transported to the power station.

Most importantly, what would be the total cost of the biofuel delivered to the gas turbine for a system to generate 24 GW of power, in ‘peaker’ plants with an average at of 13% capacity factor and all generation over a few short periods in winter?

The metabolic rate observation seems to be an equivalent formulation of the ‘EROEI cliff’ described here. That is an advanced society needs high net yield primary energy sources. Peter Lang’s detailed calculations seem to bear this out. Biofuels are a useful niche where they accumulate as waste at places like dairy farms, fast food restaurants, landfills and sawmills. Behind the scenes diesel and coal fired electricity are doing the real work. Waste product biofuels are quite different to growing and harvesting them on a massive scale as a matter of necessity.

Household batteries coupled with smart meters may be a way to use and store widespread PV. In Australia that could mean perhaps $50k investment per house times times say 5m homes or a mere $250bn.

There seems to be no simple calculation that comes up with an optimum renewables penetration like 20% but we know it is less than 100%. We could eventually discover that number if the biases were removed from the system, perhaps subject to an overall carbon constraint.

Ah Peter Lang… When he is good, he is very very good indeed. Invaluable contribution, thank you Peter.

Peter Lang — Well done indeed. I suggest using generation curtailed rather than spilled as the later strictly only applies to hydro operation upon resevoir at capacity or to meet minimum streamflow requirements at times of low demand for electricity.

Peter, let’s hope you get more response from the EDM team than we got from BZE on the ZCA2020 critique.

This kind of in-depth analysis (as with the ZCA2020 critique) deserves a comprehensive response from the authors of the original paper. To not respond suggests an irresponsible disregard for the potential value in the critique. I trust you will make sure that the EDM team get a copy of your paper.

This is a huge and truly impressive piece of work. Peter is to be congratulated for the effort he’s put into this and the detail of his analysis.

The discussion of each of the component technologies is particularly valuable, and could stand alone, without reference to the EDM paper. If anyone is finding the sheer size of this paper offputting, I’d suggest reading the “Comments on the technologies and assumptions” section.

It demonstrates that one cannot simply abstract a high level representation of these generators and bolt them together to make an energy system. Rather, one has to deal with the messier physical realities of the dynamics and latencies, costs and scaleabilty, spatial distributions and temporal variabilities, and not least the economics. To borrow a term from philosophy of mind, it is their qualia that matters, and that many of the renewable plans ignore.

The biogas discussion in particular brought this home for me. The substitution of biogas for natural gas in discussion of backup power looks like a sleight of hand – they aren’t substituteable, as Peter lays out in these points:

– the existing biogas capacity is not substantially gas turbines but reciprocating engines – steam power, or perhaps internal combustion. Small, local, and with very different characteristics to a gas turbine.

– The biomass required to cover the winter gap in solar amounts to ~74% of Australia’s irrigated land.

– Supplying a biogas plant would require a ~1-200 truck loads every day from about ~100 km catchment.

– The latency between biomass collection to biogas production is of the order of a month. So like other technologies the biogas plant capacity needs to be “overbuilt” so stockpiling feedstock and product biogas can begin ahead of the winter demand.

– Large biogas storage tank capacity must be available at the biogas generator sites, sufficient to cover a large chunk of national energy demand through the winter weeks.

The cost of this would be enormous, even if it weren’t practically impossible, for infrastructure that is mostly to be used in a single season.

High level descriptions of systems are easy; detail is hard. The inclusion of a large biogas component in the EDM work suggests a cavalier disregard for detail, and therein hides the devil.

Peter, excellent analysis.

Like JN and JM, I think the biofuel proposal is hugely problematic.

Kessides and Wade have an interesting measure of dynamic EROI, which permits a more nuanced measure of EROI. They make the point in regards to wind (although the same applies to biofuels), that despite possessing a similar static EROI to coal, the ability of wind to rapidly scale up its production by

bootstrapping its own energy appears to be far more limited. I suspect this is what most of us suspect anyway – are wind, biofuels, etc going to be able to generate enough surplus energy within ecological limits to run the mines, processing, factories, transport, homes, agriculture etc.. that is required in a modern industrial society?

http://www.mdpi.com/2071-1050/3/12/2339/pdf

I agree with Elliston et al. that there are many potential opportunities to exploit agricultural wastes (and other wastes), but the whole bioenergy discussion is a huge can of worms, ecologically, economically and logistically.

[…] answer whether a system of 100% renewables can meet Australia’s 2011 electricity demand. Detailed critique and analysis shows that it cannot. Costing done independent of the study itself (… For the EDM-2011 baseline simulation, and using costs derived for the Federal Department of […]

DBB, thank you for that suggestion. You are correct that “spilled is not a good term, but it is widely used and is used throughout the paper I critiqued.

There is a better term that is commonly used, but it has slipped my mind for now. I’m sure I’ll remember it as soon as I post this comment.

Martin Nicholson: good points. Thank you. Yes, I will send the authors a copy of the PDF. And thank you for your help.

John Morgan thank you for your comments, and for all your help too. I suspect your comments also apply to liquid biofuelled gas turbines.

Graham Palmer, thank you for your interesting comments and excellent help too. I hope you will expand on this as the thread progresses.

Peter Lang — NREL uses curtailed.

Peter, well done.

It is a nice critique, the cost analyses in particular are excellent. I really hope they respond (unlike BZE!) so we get some constructive discussion happening between BNC and Elliston, et al, and hopefully identify some common ground.

I have some extra points to add to the PV section, I’ll get back to you soon.

Cheers

Although only briefly mentioned in both the Elliston paper and critique, the issue of peak demand reduction is critical in a reducing the need for infrequently used capacity. The Elliston paper, the BZE report, and nearly every pro-renewables proposal assumes that energy efficiency reduces both consumption, and peak demand ipso facto yet the literature on the relationship between efficiency and peak demand is actually quite sparse.

Putting aside Jevon’s Paradox, perhaps the greatest challenge in these Australian plans is providing sufficient capacity for Melbourne during winter. Forget smart grids, TOU pricing, and extra insulation – on a near freezing morning or evening, households want to press the thermostat and get warm. This is an essential service that must be provided reliably and affordably for all households as an issue of social justice. The key issue is that when people get home from work and turn on their heater, and it runs at full capacity for an hour, it doesn’t matter whether extra insulation reduces the annual energy consumption, the peak demand remains. Ironically, leaving the heater on all day will result in reduced contribution to aggregate peak demand during the “peak hour”, but consume more energy. It can be shown that energy efficiency can provide some aggregate reduction in peak demand, but the relationship is by no means simple, and usually limited.

In this regard, the Elliston paper is far more sensible than the BZE report, which advocates shutting down the natural gas network. The large scale conversion to electric heat pump would worsen peak demand due to the need to run a defrost cycle on the coldest days, and operate at substantially reduced efficiency at low ambient temperatures.

Brilliant work, Peter.

Barry, thanks for bringing this to us.

Care to tell us why this is the case. I don’t see where the authors have widely missed the mark on hydro storage capacity and requirements. 2.2 GW capacity at 20 GWh DOES reflect an upper storage limit … it’s roughly 9.1 hours of continuous pumping (before the max is reached). Water availability is not factored into their model. I also don’t see where they intend to use stored energy during “most of the year” for release during a “few short periods in winter.” As they state in the paper, PHES is utilized for storing “spilled” energy and daily balancing to maximize yearly gross energy production: “In this scenario, pumped storage hydro plants are charged using spilled energy and dispatched first to maximize the energy supplied year round” (p. 3). They state the main benefit from hydro storage (at the low energy storage levels achievable in Australia) is not meeting peak demand, but offsetting biogas consumption (p. 9).

Your other recommendations are spot on: it would be great to have a run of their model on 5 minute scale, LOLP analysis (rather than statistical comparison with 2010 load profiles), and addition of a non-solar dependent 24 hour baseload variable (geothermal, nuclear, CCS) and look at how this changes operational criteria (with respect to spillage, gas utilization, storage demands, unmet demand, etc.). Since there is a great deal that they are not doing in this study yet (Slide 7: providing a plan, covering all regions, covering all end-use, demand response analysis, transmission modeling, economics), it sounds like NOW is a pretty good time to have a constructive impact on the full shape and scope of this long-term research project (for this conference paper, and in the future).

Graham Palmer,

Thank you. Excellent points.

I’d add, if we want to reduce emissions from all energy consumption, electricity will have to replace gas for heating. That means the peak Melbourne cold morning peak demand would be even higher.

John Bennetts, thank you for the comment. Can you suggest any refinements for the transmission estimate (see Appendix 2 in the PDF version)?

EL,

Thank you for your questions and comment. I’ll answer your questions in two separate replies.

I need to provide more explanation on this. I’ll give a short answer here and intend to write up a more detailed comment to post on the Pumped Hydro thread and perhaps on OzEA to add to the previous comment here http://www.oz-energy-analysis.org/feed/show_me.php?comm=OzEA_DG0002 which addressed the question:

EDM-2011 cited this comment on OzEA as the basis of their pumped hydro energy storage capacity, but they did not realise there is a constraint on the rate at which energy can be stored.

I need to add to the OzEA comment an explanation of the rate at which energy can be stored in the three existing pumped hydro plants.

Is the short answer:

“20 GWh DOES reflect an upper storage limit”. This satatement is correct.

“2.2 GW capacity”. No. That is not correct. Wivenhoe is the only pure pumped hydro scheme in Australia. The other two PHES plants have some pumped hydro capacity within a plant that is mainly a hydro plant. EDM-2011 attributed the full generating capacity of these plants to pumped hydro.

Only 0.9 GW of generating capacity can be attibuted to pumped hydro. The remainder of the 2.2 GW EDM-2011 assumed should be attributed to hydro. Furthermore, there are energy losses in pumping and generating, so only about 75% to 80% the energy can be recovered.

Wivenhoe PHES:

All the water Wivenhoe PHES plant uses to generate power must be pumped up from Wivenhoe reservoir. It can store energy (that is energy that can be recovered, after losses) at the rate of about 328 MWh per hour. It pumps when demand is low and electricity is cheap – between about midnight and 6 am (longer on weekends). It is on standby (spinning and ready to go to full power within less than 1 minute) for about 12 h per day and generating to meet peak and intermediate demand for about 7 hours per day (at variable power output). It generates a little during standby to balance power and frequency fluctuations in the grid. It cannot pump while it is generating or on standby. Because it is needed to be generating and on standby during the day, and because power is cheap at night, the pumping is done at night when the plant is unlikely to be needed for generation.

It takes a lot of energy to start pumping the water. The weight (~23,000 tonnes) of water must be lifted up 100 m against gravity and accelerated from 0 to 3.6 m/s velocity each time pumping starts. Therefore, it is not economic to repeatedly stop and start the pumping. The pumps are not variable speed so once started they run at their constant pumping rate of 207 m3/s.

Therefore, the pumps should only be started if they can be assured they will pump for at least several hours (e.g. 5 hours, but I said let’s assume a minimum of 4 hours to be economically viable).

If we assume an average of 5 hours of pumping time per day and energy storage at the rate of 328 MWh per h, then Wivenhoe can store about 1,640 MWh per day.

Tumut 3 has 1,500 MW of generating capacity in six generating units but only three have pumps and the power of the pumps is only little more than half the power of the generators. So it is not appropriate to assign the 1,500 MW of Tumut 3 generating capacity to PHES.

Bendeela & Kangaroo Valley – similar comment to Tumut 3.

See more details here:

http://www.oz-energy-analysis.org/feed/show_me.php?comm=OzEA_DG0002

EL @ 10 February 2012 at 7:21 AM

Part 2 to my reply to your questions

But EDM-2011 also point out the system they simulated cannot meet the demand on some days in winter. EDM’s figure 2 does not make the problem clear because the 0 to 2.2 GW on the vertical axis has been truncated. This is where the pumped hydro should be displayed. So, I refer readers to their Slide 12 here: http://www.ceem.unsw.edu.au/content/userDocs/Solar2011-slides.pdf.

The dispatch order has been changed so pumped hydro is not the first to be dispatched. The dispatch order is:

• Wind,

• PV,

• CST,

• pumped hydro,

• hydro,

• gas turbines running on biofuel.

This is a more sensible and realistic dispatch order, than the one presented in the paper, from the point of view of trying to minimise the cost of electricity (given the technologies assumed by EDM-2011, their capacities and capacity factors).

Slide 12 shows that very little pmped hydro is available during the critical days in winter. For the 8 days shown in Fighre 12, there is no pumped hydro generation on four days, and very little on the other four. In fact, the the CST plants have not even been able to recharge their storage on those days.

My point was that the pmped hydro is most needed on those days in winter. To be most effective, pumped hydro would need to be maitained at full storage before entering those periods in winter. That is storage throughout the year until those critical periods in winter. This is what is critical for reducing the total capacity of biofueled gas turbines that would be required to provide a reliable electricity supply. The use of pumped hydro to reduce the amount of biofuel energy generated is a seaparate issue from the peak generating capacity required.

Just to repeat the point of your comment/question:

The point I was attempting to make is that pumped hydro is of little value in helping to meet winter peak demand. It also plays only a small role in summer at huge cost to avoid a little generation from biofuels (from looking at Slide 11).

I hope this has addressed this comment/question satisfactorily.

Just to head off any tendency to get down into a pedantic discussion about points of figures that have no significant bearing on the costs, can I suggest that we focus discussion on issues that do have a significant bearing on costs.

Sure enough, charge rate does appear to have a bottleneck at existing pumped hydro facilities (and other hydro plants) in Australia. If they intend to continue to use existing facilities in their calculations, they will have to update their figures in their model, and adjust for any efficiency losses for shorter term charging cycles. Perhaps this is what they meant when ruling out “water availability” in their calculations … excluding both environmental resource constraints and charge rates on existing facilities (up to full available capacity). It should be helpful to have these numbers published and documented here and elsewhere.

As concerns feasibility and costs of PHES in their paper, I’m not sure why they limit their analysis to “existing hydro” when looking at energy storage options for NEM? They are clearly proposing a broad buildout of generating technologies (CST and more), why not do the same for energy storage and run their model to more fully cover the winter period, maximize capture of spilled energy, and use less biogas on an annual basis? In Australia, energy storage from pumped sea water should be an option (anybody else know about specific proposals). Japan has an operating plant (31 MW with about 6 hours of storage), and Ireland is looking to do the same (980 MW with some 6 hours of storage). A Diurnal Storage Presentation (p. 14) at a recent DOE energy storage workshop suggests ocean pumped and variable speed PHES is less than five years from commercialization (with stainless steel components and fiber-reinforced plastic tubes in penstock and tailrace to minimize corrosion and barnacle concerns). A peer reviewed study from 2010 suggests CAES as a more affordable option than PHES for Australia, with an estimated 15.4% rate of return on capital investment (as compared to 9.6% for a sea water pumped hydro plant). Natural caverns, old mines, depleted gas, and aquifer reservoirs may be available for larger CAES facilities. Obviously, with lower cost fossil fuels available for capacity reserves there’s not much economic incentive to currently pursue these more expensive storage options (unless rising fuel prices, high marginal costs, supply interruptions, policy mandates, carbon costs, technology breakthroughs, or other externalized costs of fossil fuel generation are added to the picture).

One other issue concerning cost. Traditionally, PHES has been a strategic tool for baseload developers, especially in helping with thermal power efficiency and flattening out load variations. So while expensive, it often has operational and power utilization benefits that far outweigh it’s per kWh levelized investment cost. Increasingly, markets are starting to reward these benefits, and so comparing this to the wholesale rate of energy may not be particularly illuminating. How to properly price the value of stored energy (for such thing as distributed generation and power quality end-use, ramp rate control and load time shifting, voltage regulation and capacity services, transmission stability, and anything else) is anybody’s guess at this point. At the same DOE conference mentioned above, the lead presentation (p.49-51, and throughout) mentions a list of proposals for market reform at national level, state, and among PUCs in the US to perhaps make better use of ancillary and energy storage services (apart from generation). Perhaps something like a rate of return on investment might be a better measure for understanding the comparative costs of storage plants (rather than levelized costs of the energy that is being produced at them)?

EL,

Thank you for your comment. You say:

It is hydro, not pumped hydro, that is limited by the water inflows to the storage reservoirs. So this part of your quote is not relevant to the discussion about pumped hydro. I think EDM have, in fact, limited their total hydro generating capacity (Hydro + PHES) to about what the NEM generated from hydro in 2010. The problem I highlightred was that their allocation of generating capacity between hydro and pumped hydro is not justified (IMO).

It is the figure of 2.2 GW of pumped hydro generating capacity that is the misleading figure they have used (IMO). I’d suggest they shlould use 0.9 GW of PHES generating capacity because that is the sustainable maximum. The average would be much less than this (if charged with coal or nuclear) and much, much less if charged with intermittent renewables).

I’d give two reasons:

1. Because the Greens and environmental NGO’s and their followers are almost as strongly opposed to hydro ans they are to nuclear (not just in Australia but in other developed counmtries too.

2. Pumped hydro is not viable unless you have low cost baseload power supply – like brown coal or nuclear (if we would allow low cost nuclear).

If you would like to get some background on the viability of pumped hydro in Australia could I refer you to this BNC post and in particular to the two reviewers comments included near the end of the article.

http://bravenewclimate.com/2010/04/05/pumped-hydro-system-cost/

Also, you will find many excellent posts in the comments following that article.

EL. That is an excellent idea. Why don’t you set an example for other BNC readers. Shw them how easy it is. Open the spreadsheet linked at the top of the thread, then change the input parameters and record the change in:

1. Capital cost for the whole system

2. Cost of electricity for the whole system (excluding the cost of electricity for the existing NEM grid network

3. CO2 abatement cost for the whole system

You could produce a chart showing the cost of your optins and link it for others to see here.

The inputs you’d need to change are:

1. the generating capacity for PHES (You’d need to change the capacity factor and perhaps the generating capacity for OCGT (i.e. gas turbines running on biofuels) to keep the total electricity generated at 204,400 GWh.

2. the interstate transmisison system capacity (to carry more power from the renewable generators to pump the water)